Home » stone fabricators

Articles Tagged with ''stone fabricators''

Web Exclusive

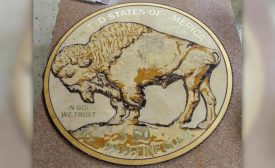

Buffalo Medallion Cut in Stone

A three-dimensional buffalo floor medallion was produced by Creative Edge Master Shop with advanced waterjet technology – demonstrating quality precision and craftsmanship in stone fabrication

March 14, 2018

Creative Countertops increases efficiency in its stone shop

Creative Countertops of Poulsbo, WA, runs a small shop with a few pieces of equipment, but with an efficient workflow in place the company is a top producer in its region

March 7, 2018

Cosentino Group Achieves Record High Revenue in 2017

Cosentino sets record high in 2017 with over $1 billion in revenue and $70 million in net profit

February 28, 2018

Fabricator Issues and Solutions

Moderated by Tony Malisani of Malisani Inc. in Great Falls, MT, the Atlanta Stone Industry Education Seminar drew a group of fabricators who came to share experiences and listen to how their peers deal with various issues that arise in a stone fabrication business

February 15, 2018

Gecko Solid Surface Solutions Rises from the Bottom to the Top

Business major turned stone fabricator, Augie Chavez, began his own fabrication business after moving to Texas more than a dozen years ago, which is now among the most successful stone shops in the state

February 1, 2018

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the international stone industry trends.

SUBSCRIBE TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing