Remember getting that first smartphone and how it changed everything about your workday? Phone calls, text messages, web access, email and so much more in the palm of your hand, increasing your daily productivity and allowing you to quickly react to the needs of your customer. For the modern fabrication facility, implementing SawJet technology and digital processes can have similar impact on the shop productivity.

SawJet technology, the combination of a saw and abrasive waterjet integrated with a cutting machine, can reduce the time associated with nearly every step in the fabrication process when compared to manual processing. With this technology, a saw produces fast cuts wherever there is a straight cut, and the waterjet takes over to handle curves, faucet openings, sink openings and other complex shapes. In addition, for cuts in areas where an overcut will damage the adjacent piece, the saw can stop the cut short and the waterjet can finish the cut tight to the edge. This allows for much greater material yield and eliminates the need to move pieces on the cutting table in order to perform an interfering cut.

SawJet technology is a digital technology, requiring a CAD file in order to define where the machine will perform cuts on the slab. This typically means measuring the job with a device such as a laser templator instead of manually measuring and creating physical templates. While this might be initially intimidating to those who are new to digital processes, fabricators quickly find that this technology allows them to cut templating time in half, and the process results in less errors when compared to manual measurements. In addition, the template file can be emailed back to the shop remotely, allowing the templator to move on to the next job quicker.

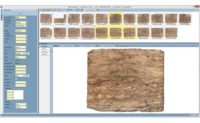

Once the digital file is available, all of the steps in the fabrication process are defined and it becomes easy to move on to the cutting process. The file can be loaded into the SawJet machine, and the cut shapes are overlaid on a photo of the slab. The operator can then move the shapes over the image to place the cuts for best yield and visual layout. This process typically takes less than five minutes — saving a great deal of time over completing a manual layout that can take 20 minutes or more. With the digital layout and the benefit of the SawJet process, it is common for yields to increase by 10 to 20%, resulting in better profitability and

less remnants.

Another huge benefit in using SawJet technology is that the cutting process is much faster than on a manual bridge saw. A job that would take one to two hours on a manual saw can be cut in 20 to 30 minutes with a SawJet. In addition, since the SawJet can cut sink openings, faucet holes and curved cuts, several downstream steps are eliminated. This saves labor, reduces material movement in the shop and allows jobs to go directly to polishing or CNC edge finishing. Also, for shops that utilize CNC technology, additional capacity becomes available as some of the operations normally carried out on these machines is completed upstream in the SawJet process. This also reduces tooling costs on the CNC since cuts normally performed by finger bits are no longer required.

The combination of labor savings, material savings, reduced errors, faster processing times and a reduction of downstream processes makes SawJet technology a strong consideration for any fabricator that is looking to make a huge impact on the productivity of their countertop manufacturing operation.