Superabrasive’s Lavina 7 Pro is now carried through Braxton-Bragg.

The new Lavina Pro line from Superabrasive features more horsepower and an improved operation and driving system to match the new level of performance and productivity. Along with the standard sizes of floor polishers, Braxton-Bragg will also carry the latest addition to the Lavina family of machines, the Lavina 7 Pro - a brand new corner machine.

Lavina floor polishing machines are planetary movement machines featuring 1, 3 and 6 heads. The planetary motion results from the friction between the tools and the floor, which allows the tools to spin either clockwise or counterclockwise. This way the tool will not force itself against the surface’s resistance. Instead, it alternates directions and jumps from high to low points rather than from low to high points.

All Lavina models except the corner edger can be used for wet or dry applications. The wet set-up is enhanced by a self-leveling skirt that prevents slurry from spraying out, a centrifugal force that removes the slurry under the machine and ensures a clean contact between the diamonds and the floor and water cycles that deposit the water on the periphery of the working area. The dry set-up is also complemented by a self-leveling skirt that prevents dirt/dust from spraying out and two hoses located at the bottom of the machine that absorb the accumulated dust and ensure a clean contact between the diamonds and the floor surface.

On all Lavina machines, the tools touch the rim of the skirt. This way, the only distance between the tools and the edge of the working surface is 5 mm or 1/5 inch (thickness of the skirt). Most other machines have a 2-inch gap, reports the manufacturer. The small 5-mm distance keeps operators from having to do the edges by hand or with an additional machine, thus saving them time and money, according to the manufacturer.

www.superabrasives.com

www.braxton-bragg.com

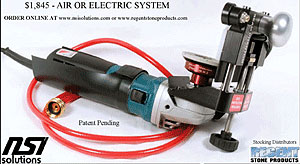

NSI Solutions’s Phantom SL3

www.nsisolutions.com

Flow International Corp.recently launched the Paser 4 Ultra Component Life (UCL) abrasive waterjet cutting head.

Flow’s waterjet expertise, extensive testing and R&D have led to one of the latest abrasivejet enhancements - the Paser 4 UCL cutting head with a low profile water on/off valve, reports the company.

Whether the Flow pump is rated at 40,000 psi, 60,000 psi or even at Flow’s industry leading 94,000 psi, Paser 4 cutting technology delivers optimum cut quality, speed and operating efficiency. Orifice life is increased three to five times while abrasive consumption is reduced, resulting in substantial savings.

www.flowcorp.com

NSI Solutions’s Seam Phantom