Home » Keywords: » material handling equipment

Items Tagged with 'material handling equipment'

ARTICLES

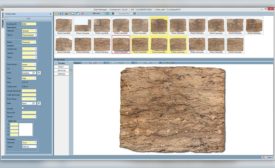

Advances for safe handling of stone material in the shop

Slabsmith’s ability to create digital slabs allows fabricators to spend less time handling slabs, saving time, being safer and cutting expenses

May 14, 2018

Material Handling: An underlying opportunity

Taking some time to examine your fabrication operation to ensure the most effective procedures and equipment is being utilized to move stone products around the shop can result in a safer work environment and more efficient production process

April 1, 2017

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the international stone industry trends.

SUBSCRIBE TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.jpg?height=168&t=1709053914&width=275)