Yancy and Tamie Devine, owners of Old World Granite & Stone (TX), were ready to take their stone fabrication business to the next level. But to do so, they needed a way to make production faster, leaner and far more reliable. They turned to Park Industries for assistance in upgrading their facility. The lineup of new machinery resulted in the ability to produce nearly 1,000 square feet per day with only four employees in the shop.

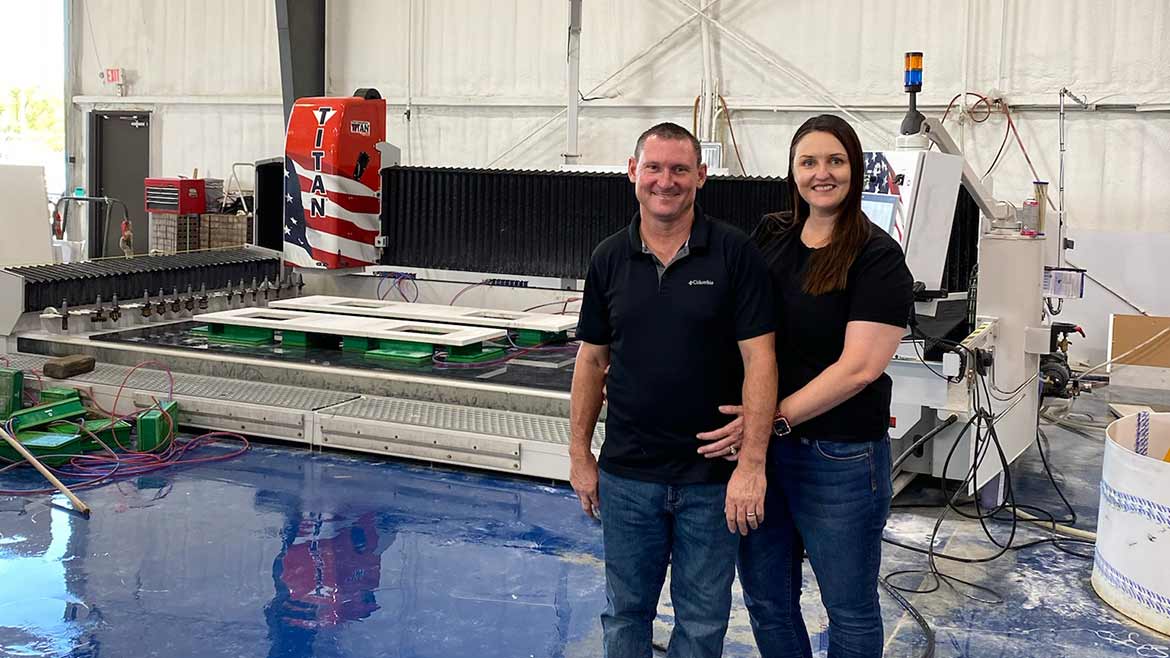

Yancy and Tamie Devine, owners of Old World Granite & Stone (TX). Photos courtesy of Park Industries.

After acquiring the business in 2012, the couple spent the better part of the next decade cutting with their Yukon bridge saw. They dropped sinks and polished by hand. “We were stuck in a rut,” said Yancy Devine. “You can’t grow and had to rely solely on labor. One day we came in and no one in the shop showed up for work. We were tired of the stress and the fight to get jobs done.”

New Shop, New Machines, New Life

The Devines decided they could not wait any longer to make a change. In 2018, Yancy quit his day job as a builder and joined the company full time. His first order of business? Building a new 20,000-square-foot shop. Yancy did all of the construction and layout himself, starting “from dirt,” as he explained. They also began researching machines to automate their processes when it was ready.

In November of 2020, the building was completed and looking pristine with a gorgeous new showroom. It even included blue epoxied floors in the shop to help keep it tidy.

Next, it was time to equip the shop. Not even a month later, trucks rolled up to Old World Granite & Stone via I-35 South from St. Cloud, MN. Among the machinery installed was a two-table SABERjet™ XP CNC sawjet, a TITAN® 3700 CNC router, a FASTBACK® II edge polisher, a HydroClear™ Pro 95 water system and a Pathfinder digital photo station. A second TITAN 3700 would be added soon after.

With a new machine for every aspect of fabrication, the company’s production and efficiency was totally revamped in one game-changing leap. Old World Granite & Stone was now a 100% digital shop.

An investment in a two-table SABERjet XP CNC sawjet and a TITAN 3700 CNC router – both from Park Industries – has significantly contributed to making Old World Granite & Stone (TX) a more efficient and productive shop.

In the Shop

Yancy explained they chose the SABERjet™ XP CNC Sawjet to lead the charge for their sawing production.“The SABERjet XP is a beast for high-speed production,” he said. “I can cut 20 to 25 slabs a day on it.”

Yancy also credits the TITAN® 3700 CNC routers for increased efficiency in the shop. “The TITAN is my favorite machine,” said the fabricator. “You can get so much out of it and the machine can do so much for you. The tool life I am achieving with it is insane. I am getting 4,500+ feet on my finger bit and am still on my first set of flat polish tools at 26,000 feet on the metals -- even though we primarily do flat edges.”

Sink polishing has been transformed for them. It used to take them all day to fabricate and polish six sinks. Now with the TITAN, they can do that in a little over an hour.

Moreover, Yancy explained how the HydroClear™ Pro Water System has rounded out their fabrication process. “We couldn’t do what we do without the HydroClear™ PRO system – water is extremely important for any shop,” he said. “There is no maintenance on it besides changing the bag out once every three weeks and adding some chemicals once a month. It’s been a set it and forget it. The recycled water quality is great and it keeps up with all of our machines without any problems.”

Among other new equipment from Park Industries that was installed was a FASTBACK II edge polisher, a HydroClear Pro 95 water system and a Pathfinder digital photo station. The upgraded shop has lead to nearly 400% more production with 75% less labor utilized, according to Yancy Devine.

Significant Results

The Devines runs their shop like a “ballet” and has been able to accomplish quite a bit with their new machines. Their growth based solely on the numbers is astonishing -- nearly 400% more production with 75% less labor utilized. Before going digital, the shop produced 200 square feet per day or less with 10 employees. Currently, the shop produces between 800 to 1,000 square feet per day with four employees.

“It’s even harder to find people these days, so it feels freeing that, if needed, one person can run the entire shop,” he said. “The efficiency we’ve gained is insane. I couldn’t imagine being where we were four years ago. We can confidently commit to any job now and our lead times are down to one week. We are a preferred vendor because of our reliability. We couldn’t have accomplished that without our machines.”