Bergerson Tile & Stone of Astoria, OR, was founded in 1978, and it made significant investments in digital slab-processing technology and software last year.

Founded by Dave Bergerson as a tile supplier and installer in 1978, Bergerson Tile & Stone of Astoria, OR, has been processing stone for the past 15 years, but it got “serious” about countertop fabrication in July of last year with the purchase of a CNC stoneworking center and advanced software to help the shop run to maximum efficiency.

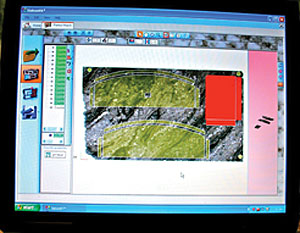

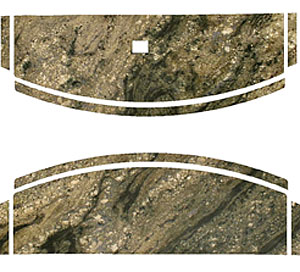

One critical piece of technology is Slabsmith™ software from Northwood Designs, Inc. of Antwerp, NY. The system was designed as both a manufacturing aid and sales tool. Its Perfect Match™ module is for optimized nesting, and allows the user to quickly and easily manipulate the nest for the best results. “We’ve been very happy with the system,” said Trask Bergerson. “After seeing their job on Slabsmith, I’ve never had someone get out of the chair without writing a deposit. It really makes the sale.”

“It was killing me to have to try and do some of the high-end work we were doing with manual equipment,” Bergerson continued. “I saw some digital shops, and they had a completely different approach; there weren’t wires all over the place. Our financial advisers were scared of the investment, but when we looked at the numbers, we saw that our costs for production would actually go down.”

“We’ve been very happy with the system,” Bergerson said. “After seeing their job on Slabsmith, I’ve never had someone get out of the chair without writing a deposit. It really makes the sale.”

But it is a whole new game, and people need to look at it this way. It is possible to expand and grow in difficult times, and we are gaining market share to the point that we are looking okay.”

When processing jobs, the company begins by templating the space using a Prodim Proliner 6 digital templating system, which was purchased from Blick Industries of Laguna Beach, CA. The data that is collected is then processed by computer.

The bidding process

Bergerson said that with the technology currently in place, templating is often part of the bidding process. “We didn’t know how to bid some of these intricate jobs. So what we do is go out and template the job,” he explained. “As soon as I have the template and put it in the system, I nest the job and show them two or three variations. AlphaCAM has a free add-on called ‘Simulation.’ It is a data sheet that estimates how long a job will take to process. It goes on optimum performance, and it comes very close. I just did this with a restaurant job. We are able to manipulate things using the simulations and get a time. So you figure how much you want to make per hour, plus material costs, and it helps you come up with a number. I ended up with a winning bid.”

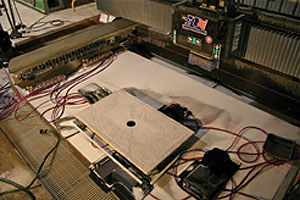

In terms of large-scale machinery, Bergerson Tile & Stone’s shop is centered around its CNC stoneworking center, which is from Northwood Machine Corp. of Louisville, KY.

“[We have the] Northwood FabCenter, the third model,” explained Bergerson. “That’s the heart of it. We have one machine, and we are operating it in the truest spirit that it is intended for.”

Following the CNC model

In terms of large-scale machinery, Bergerson Tile & Stone’s shop is centered around its CNC stoneworking center, which is from Northwood Machine Corp. of Louisville, KY. “We have a 100% digital shop,” Bergerson said. “Mark Lauzon [a stone fabricator who also represents Northwood] set my shop up, and he modeled it with a digital Northwood FabCenter, the third model. That’s the heart of it. We have one machine, and we are operating it in the truest spirit that it is intended for. Some fabricators have rejected the notion of using the machine as intended, which is to use it as a saw and a router. Rather than block-cut the piece on a bridge saw and oversize it, we oversize everything 3/16 inch on the FabCenter, except the scribe work, and then use it as a router. That’s basically the way a SawJet runs. We’re not a big production shop, so this method really works for us.

Bergerson Tile & Stone uses its Northwood CNC stoneworking center for cutting along with edge processing.

Slabs and workpieces are maneuvered around the shop using a Gorbel overhead crane system with vacuum lifters from Wood’s Powr-Grip of Laurel, MT. In addition, the workpieces are protected as needed using the Sink Hole Saver, a bar clamp system from Omni-Cubed, Inc. “I have a 10,000-square-foot warehouse, which is very narrow, so the one-machine footprint made a lot of sense to me for a lot of reasons,” he said, In speaking on the company’s machinery investments, Bergerson said that ownership took a methodical approach. “I never had a bridge saw, so that was never part of our protocol,” he said. “The concept of becoming a CNC shop makes you embrace some important things. You are a manufacturer as opposed to an artist, and you need to understand this. We move materials and program data for a living, so we needed written protocols to understand that we want to do things the same way every time. For example, we always rod sinks - no matter what. All of the employees and sales staff have to use standardized terminology and standardized methods. For example, the word ‘bullnose’ can mean different things to different people, so we standardized exactly what that means.”

Workpieces are oversized 3/16 inch on the FabCenter, except the scribe work, and then the machine is used as a router.

“Now that we’ve established all of this, there are some ancillary benefits. For example, I can track the lineal footage wear of my bits. It also gives you freedom as an owner, because you don’t have to be watching the shop every single minute. You can be out making relationships with clients.”

Slabs and workpieces are maneuvered around the shop using a Gorbel overhead crane system with vacuum lifters from Wood’s Powr-Grip of Laurel, MT.

Production

Over the course of this year, Bergerson Tile & Stone has seen its production change in terms of volume and project type. “We average four to five kitchens per week, and that has come about in early 2009,” said Bergerson. “Initially when we started, most of our work was exotics and complex five-slab kitchens. Now we’ve been grabbing market share, and we’re doing all types of work to keep a full schedule. We’ve even been working in Ubatuba and middle-of-the-road slabs. People aren’t necessarily doing complete remodels where they are doing tilework in the kitchen, but everyone coming to us is doing the kitchen tops. The builders, by and large, don’t have projects clicking at their heels, so they are now installing tile. But they can’t pick up a slab of stone and cut/install it themselves.”

Workpieces are protected as needed using the Sink Hole Saver, a bar clamp system from Omni-Cubed, Inc.

A rail saw is also in place for cutting as needed.

Challenges

Speaking on challenges since the investments, Bergerson said that establishing clear communication with customers was critical. “My costs actually came down, and we were able to get very competitive on simple kitchens,” he said. “My quality went up by light years. I was cheaper and faster, and we worked to be nice to deal with. And people were sort of suspicious that there was some sort of catch. I have spent a lot of spare time making promotional CD-ROMs so people could understand what we were doing and the changes we made. People get it, but it can be an uphill battle. It was something that never occurred to me.”

The company averages a total of four to five finished kitchen projects per week.

Projects are completed in a range of marble varieties in addition to granite and other materials.

Sales and service

According to Bergerson, the investments in equipment have helped them offset the overall decline in the economy. “More and more, we are leveraging technology to our advantage,” he said. “If I didn’t do so, we would have a much lower batting average when everyone is price shopping. This allows us to keep the schedule full. The best month we had was November.”Working in the Oregon market, Bergerson Tile & Stone completes projects across a broad region. “We service a 100-mile radius,” Bergerson said. “I am on the phone all day, and I am tracking every single job and look to make contact with everyone. I want to know my service area - including every side road and cul-de-sac.”

Kitchen projects completed by Bergerson Tile & Stone range from more advanced high-end jobs to traditional layouts.

However, Bergerson added that the clients out there are expecting more for their money. “The higher-end clients who have discretionary income are demanding service like I’ve never seen before,” he said. “And they’re also demanding discounts because they know what is going on out there. And right now, you are really being taken to task. But the well-to-do people with money to spend are utilizing their money to the maximum effect. They are buying vacation homes because it is a great bargain for them right now. So service remains at a premium, but we’re not getting paid for it like we used to.”

Bergerson Tile & Stone also supplies custom flooring projects.

Sidebar: Bergerson Tile & Stone

Type of work: residential kitchen countertops, flooring and tileworkTechnology: Slabsmith nesting/management system from Northwood Designs, Inc. of Antwerp, NY; Prodim Proliner 6 digital templating system from Blick Industries of Laguna Beach, CA; FabCenter CNC stoneworking center from Northwood Machine Corp. of Louisville, KY; Gorbel crane system equipped with vacuum lifters from Wood’s Powr-Grip of Laurel, MT; Sink Hole Saver bar clamp system from Omni-Cubed, Inc.

Number of Employees: 25 (five in the slab division) Production Rate: Four to five kitchens per week