Founded in 1991, Mario & Son opened a new state-of-the-art stoneworking facility in Liberty Lake, WA, in 2007.

In business for nearly two decades, Mario & Son of Liberty Lake, WA, has steadily grown and invested back in its operation. These investments have included a range of CNC equipment as well as automated state-of-the-art technology for slab transportation, bar-coding, inventory and tracking. Moreover, the company has developed a one-of-a-kind, interactive showroom to help customers understand the history and potential uses of natural stone.

In designing the showroom for the new facility, the company’s owners wanted to create a stone “art gallery” for its customers.

Mario & Son was founded by Mario Marcella, and his son, Joey Marcella, in 1991. “Prior to that, my father had been a tilesetter since 1953,” explained Joey Marcella. “I am the youngest of five. My older brother, Michael, joined the business in 1997 and became a partner in 2000. I had always been involved in the industry. I spent my summers setting tile, and got more involved in stone tile in the ‘80s - polishing edges, etc. We started doing small vanities, and it kept growing into a full-blown shop. My father had developed a reputation for craftsmanship over the years, and everyone in the area knew him simply as ‘Mario,’ so that’s how we named the company.

The showroom features stone quarry murals and an interactive “museum wall” that takes the view through the quarry and fabrication process from start to finish.

In 2007, Mario & Son took its showroom to an unprecedented level with the creation of an interactive space that highlights the history and future of the stone industry. “We believe our shop signals a new direction for fabricators as we compete in a subdued economy where customer service is paramount,” Marcella said, adding that when considering the cost of high-end stonework, it made sense to invest in the company’s showroom facilities. “When people are buying a granite kitchen or any stonework, they’re typically paying a lot of money,” he said. “There are a lot of shops nationally that have addressed this. In our area, shops are often in out-of-the-way dingy places. It didn’t seem right to the customer to have that experience. In our old shop, the slabs were all outside. It was a matter of timing and when we could afford to enhance the experience. So in 2007, after 18 years in the stone business, we envisioned and constructed a new shop to enhance the customer experience on all levels.”

A fireside seating area contributes to the comfortable environment for clients in the showroom.

A range of completed vignettes are also in place at the company’s facility.

Mario & Son’s multi-media conference room features a 20-foot-long table and backlit onyx panels.

In equipping the shop, the owners of Mario & Son have continually sought to invest in advanced stoneworking technology. “Our first CNC was a Z.Bavelloni 102-S, which we bought in 1997, and it was one of the first in the U.S.,” Joey Marcella said. “People questioned the idea of buying it for custom fabrication at the time, but we’ve always tried to be at the forefront when it comes to technology. We bought one of the first Park Pro-Edge machines as well.”

The facility is located adjacent to Interstate-90 in Washington State, providing Mario & Son with a large retail presence.

In 2007, Mario & Son purchased a 207-unit automatic warehouse from Breton of Italy. This includes powered straight line and transversal conveyors, a material “flipper” and a bar-code system.

Breton refers to the automatic warehousing system as the Automatic Resource Management System (A.R.M.S.). These systems are customized material warehousing solutions designed to automate the order-fulfillment process.

In addition to the A.R.M.S. system, other Breton equipment includes a Contourbreton NC 260K37 stoneworking center, pictured on the left in the background.

Additionally, the company operates a Speedycut FK/NC 800 saw, which has numeric control and operates with AutoCAD software.

Marcella said that extensive research went into the Breton material-handling system, which he called “the heart” of the company’s operations. “A couple of years prior to getting this built, my brother and I traveled the country and visited various shops,” he explained. “We were concerned with the continuous production concept. We looked around, and we liked what we saw. We knew that we needed a system for material storage, so we wouldn’t have to stop every few hours.”

Mario & Son also operates multiple CNC stoneworking centers from Z. Bavelloni of Italy, including the Egar 250.

For templating, the company relies on two LT-55 laser templating systems from Laser Products of Romeoville, IL, along with a Faro arm. Various projects are tracked using the JobTracker system from Moraware of Reno, NV.

Complicated cutting is done using a dual-table Flow waterjet.

Slabs are also cut to size using a Jaguar bridge saw from Park Industries of St. Cloud, MN.

Material is transported around the facility as needed using seven overhead cranes, which have a 5-ton capacity, along with five Manzelli vacuum lifters and various forklifts.

An EnviroSystem water recycling system from Water Treatment Technologies of Hampton, NH, is in place to help care for the environment.

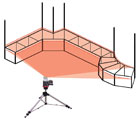

For templating, the company relies on two LT-55 laser templating systems from Laser Products of Romeoville, IL (an example of which is pictured).

Various projects are tracked using the JobTracker system from Moraware of Reno, NV (an example of which is pictured).

“We educate our employees in-house with monthly classes on fabrication and install techniques, such as new seaming methods and surface polishing, as well as group ‘field trips’ to trade shows and suppliers’ facilities,” explained Joey Marcella of Mario & Son.

The company currently processes an average of five to six kitchens per day, down from an average high of 10 per day in 2008. “We had a good 2008, but things went down in 2009,” Marcella said, adding that the economic downturn has provided the company an opportunity to improve efficiency. “It’s given us a chance to slow down and fix internal issues that we’ve always been too busy to fix. We’ve embraced that we’ve been slower than normal and used it to our advantage.”

While the majority of the equipment in the company’s current facility was purchased at the time of the move, some of the older equipment - such as the Cougar bridge saw, Z. Bavelloni Egar 320 and Marmo Meccanica 711 M - are in place at a second location, which operates under the name of Discount Stone & Supply.

Most of Mario & Son’s residential fabrication is in the high-end remodeling sector. “They are almost all remodels, and they’re very high-end custom work,” he said. “We don’t really have galley-style kitchens like there are on the East Coast. There are a lot of bump-outs and radius work combined with the straight work, so it is good to have a mix of machines.”

In addition to residential work, Mario & Son has done commercial projects such as the Terrace Condominiums in Coeur d’Alene, ID.

For this showroom space at Huntwood Cabinets, the company fabricated CaesarStone quartz surfacing with a 6-cm edge detail.

Sidebar: Mario & Son

Liberty Lake, WAType of work: residential and commercial work in natural stone and quartz surfacing

Machinery: Egar 320 and Egar 250 4-axis CNC stoneworking centers from Z.Bavelloni of Italy; Vario 6 and KSL 100MG edge processors from Löffler of Germany, Jaguar C400 and Cougar bridge saws as well as a Pro-Edge II and Wizard Radial Arm polishers from Park Industries of St. Cloud, MN; dual-table 6- x 24-foot waterjet from Flow International of Kent, WA; 711 M flat edge polisher from Marmo Meccanica of Italy; EnviroSystem water recycling system from Water Treatment Technologies of Hampton, NH; Sullair high-capacity, variable-drive compressor; 207-unit automatic warehouse (Automatic Resource Management System) from Breton of Italy, including powered straight line and transversal conveyors, a material “flipper” and a bar-code system; Breton Contourbreton NC 260K37 stoneworking center, Breton Speedycut FK/NC 800 optima saw seven overhead cranes, which have a 5-ton capacity; five Manzelli vacuum lifters; two LT-55 laser templating systems from Laser Products of Romeoville, IL; Faro arm; JobTracker project tracking system from Moraware of Reno, NV

Number of Employees: 30

Production Rate: Five to six kitchens per day, plus commercial work