Rocky Mountain Stone Co. in Albuquerque, NM, dates back to 1963 when Vince Lardner founded the stone business. “He was a mason,” explained Chris Quintana, who has been with the company for more than 20 years. “He came to New Mexico from Colorado and there was no one selling stone to masons here at all so he started a stone yard specifically targeting masons doing masonry work. Our origins are in the landscape and building stone business, when we still provide for this local market. We developed from there.

Since 1963, Rocky Mountain Stone Co., a third-generation stone fabrication business, has been servicing the New Mexico area. | Photos by Jennifer Richinelli

“We were the only stone yard here in this location for many years,” Quintana went on to say. “In the mid-80s, a fairly wealthy woman was doing her house and wanted marble counters. She came to Vince Lardner and basically talked him into it. She told him that he was set up better than anyone else so he should give it a try. I have been in that house many times and the counters are still there. That got us our start in the countertop business. It was about 1987.”

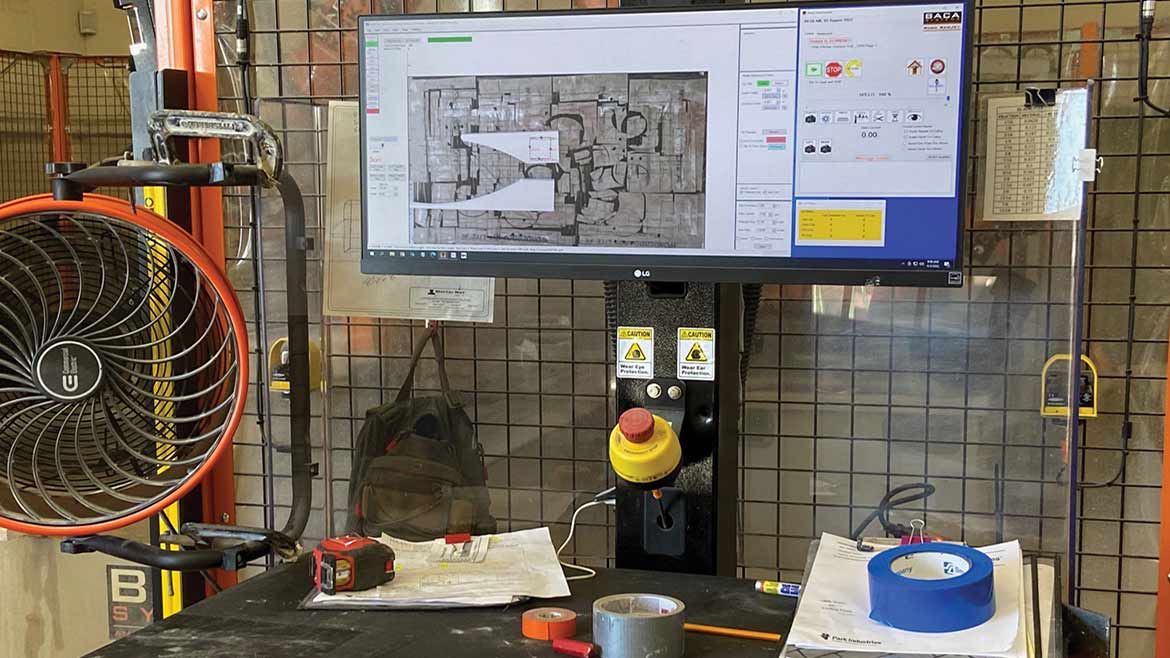

The addition of a dual-table Robo Saw Jet from BACA Systems has contributed to increased production and efficiency in the shop.

Vince Lardner’s son Scott currently runs Rocky Mountain Stone. Scott’s son, Sean, is also involved in the business. “It’s nice that we have a third generation,” said Quintana. “We are working on Sean. He has already made his way through the shop and the office. He has done multiple jobs to really learn the business from the bottom up. That’s our goal – to teach him everything.”

The company also invested in a BACA Systems Miter X miter machine.

Quintana explained that he was a stone sculptor before coming to work for Rocky Mountain Stone. “I was working as an artist,” he said. “I started in 1980. Someone came to me based upon my artwork and asked if I could do an ornate marble fireplace. I had never done anything like that before. I did my first marble fireplace when I was in my 20s and then I shifted into countertops as well.

Further adding to the shop’s high-quality production rate is a Fusion 4045 saw/waterjet and Fastback II edge polisher – both from Park Industries.

“I have been working here since 1998,” Quintana continued. “I have seen where back in the day everything was 2 cm granite – back then that’s all you could get. Everything had a laminate on it. We had a decent shop at that time -- a state-of-the-art bridge saw. It was manual, so you had this crank and the table rotated all the way around. We had wooden templates that were all glued up.

We just kept adding to the business and getting more equipment.”

According to Quintana, the shop outputs roughly 400 square feet per day.

Shop Updates

Today, the shop has expanded to include a dual-table Robo Saw Jet and Miter X miter machine – both from BACA Systems, a Fusion 4045 saw/waterjet and Fastback II edge polisher – both from Park Industries and Slabsmith software from Northwood Designs, Inc.

The company has also grown in regards to the material it cuts. “Quartzite is definitely booming, as well as man-made quartz materials,” said Quintana. “I’m an old stone guy, so I was really dead set against it when it first came out. But, now, when you see some of the material that is being made, they really mimic marble, limestone and slate. You have the durability of quartz, and in some cases, it is hard to tell the difference. So now, I am more of a believer. We are also doing a lot more Dekton, and porcelain is getting bigger too. There are definitely steps involved that are unique to cutting these new ultra-hard materials.”

Rocky Mountain Stone’s market spans the entire state of New Mexico. “Albuquerque Metro is definitely our main area, and we go to Santa Fe about three times a week,” said Quintana. “We have five installation crews – all in-house. Every morning, everyone meets here and we load up the jobs. The bulk of our area is within 80 miles, but we have recent jobs that are six and a half hours from the shop one way, so it ends up being a three-day ordeal with one day traveling there, install one day and then a day to travel back. There definitely are challenges having jobs far away from our shop. The further away from the shop you get, the crazier it gets. I make sure installers have every bit of information, and sometimes, you still have to make another trip out to fix something but we try to keep that at a minimum.”

Rocky Mountain Stone uses Slabsmith software from Northwood Designs, Inc. “Every single slab that comes in, we photograph it, with the exception of some of the quartz that look exactly the same,” said Chris Quintana. “We have a picture of every single one so when a customer chooses a slab we are able to do a layout on the slab. We are now in the process of putting Slab Cloud on our website so people can shop the slabs that they want. They actually see a picture of it. It is also very helpful with remnants.”

At the time of Stone World’s visit to Rocky Mountain Stone’s facility, the company employed approximately 50 workers, including five installation crews. According to Quintana, the shop outputs roughly 400 square feet per day. “It can be as many as seven kitchens a day,” he said. “Some crews, if they are close by, can do two a day if they are smaller kitchens.

“We are tracking square footage, but we have learned that tracking square footage is not very accurate,” Quintana went on to say. “So, we also track the money involved with that. We try to manage that more because it is more representational of actually what is happening on the jobsite.”

There are two template techs who use LT-2D3D template laser from Laser Products Industries. Rocky Mountain also works hard to keep track of their material. “Every single slab that comes in, we photograph it, with the exception of some of the quartz that look exactly the same,” said Quintana. “We have a picture of every single one so when a customer chooses a slab we are able to do a layout on the slab. We are now in the process of putting Slab Cloud on our website so people can shop the slabs that they want. They actually see a picture of it. It is also very helpful with remnants.”

The company has a showroom for customers to browse material options, including natural stone, quartz surfacing, Dekton and porcelain slabs.

A Team Effort

Creating a work culture where employees can thrive is among Rocky Mountain Stone’s priorities. “Back in 2005, we hired Owen Kingman,” said Scott Lardner. “It made a huge difference. We used to have six-week lead times. Within three months, we were down to six days out. It changed our mindset.”

Lardner explained that since that time, the company holds a daily morning meeting. “We talk about issues from the day before and how to resolve them,” he said. “It takes the chaos out of it. That was a game changer. It has made it much easier to manage everything.”

Quintana also spends time ensuring that their installation crews are topnotch. “Every day I challenge my guys,” he said. “I have our number three crew, and every day I push them harder and harder. I give them more complicated jobs and they are getting better and better. I have two crews that can handle anything thrown at them. They by far do the finest work in New Mexico. I would hold them up against anyone in the business – countrywide. They are extremely talented. I am moving my third crew in that direction.

“We also have a commercial crew and a novice crew, which is doing vanities and small kitchens,” Quintana went on to say. “My goal is to get them to move on and get another novice crew started.”

At the time of Stone World’s visit to Rocky Mountain Stone’s facility, the company employed approximately 50 workers, including five installation crews.

As many in the industry, labor is difficult to find. “Albuquerque is a small town, and we have gone through pretty much every single stone person in this town and know what they are about,” said Quintana. “Some are good – the cream of the crop – and some of them aren’t. Now we are drawing from carpenters and welders. People who have the ability to measure and read a blueprint and understand the process of doing quality work.”