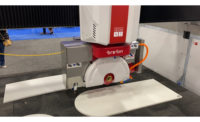

Flow’s Mach 200 waterjet is uniquely designed for today’s stone fabricators. Featuring Flow’s Pivot+™ waterjet cutting head, the Mach 200 is a competitive 5-axis waterjet with bevel capabilities, and features genuine Flow technology throughout.

“With a Flow waterjet, you can cut bevels and miters, straight lines and curves — plus complex 3D — all on a single solution and with one 5-axis cutting head,” said Tim Fabian, vice president of marketing and product management for Flow. “Waterjet truly is a perfect fit for cutting stone. You can easily cut both traditional and highly engineered stone, sinkholes, in-demand trends such as waterfalls and blunt smooth edges, creative inlays and more. Our patented UltraPierce® technology means you can make smooth chip-free cuts and avoid drilling, which is a game-changer for stone fabricators. The Mach 200, paired with Pivot+, a multi-axis solution for cutting angles up to 60 degrees, is a popular solution for stone cutting.”

The Mach 200 is backed by FlowCare, Flow’s support and service offerings dedicated to improving customer uptime and delivering programs that offer worry-free operation.

Benefits of waterjet cutting for stone

- A versatile cutting process for a variety of materials, such as natural and artificial stone, ceramic and glass, as well as bonded and laminated materials

- Precise cutting in all directions: any desired internal and external contours, sharp angles and slanted cuts

- One tool for all holes and profiles with little or no after finishing required

- No direct contact between the cutting head and workpiece

- No heat, dust or fumes

- High-quality finish together with high productivity and low-cost operation