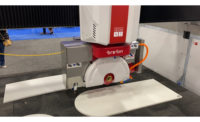

CMS Brembana has released a new generation of 5-axes bridge saw entirely managed with numeric control. Compact and easy to install, it does not require any kind of base so it can be re-located almost immediately. The machine is fitted with an abrasive waterjet cutting head which, by working in combination with the diamond blade, means natural stone and composite slab cutting can be automated when there are interferent cuts and internal angles. The machine is designed for all laboratories that cut natural stone, composite and ceramic slabs. The machine’s weight, which can be as much as 16,000 pounds, guarantees a perfect rigidity when producing:

- kitchen countertops

- vanity tops

- wall panels (internal and external)

- flooring

- doorsteps, staircases and window sills

- street furniture

Key buyer benefits include:

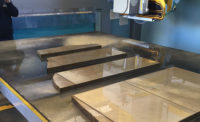

- No workability problem due to the most extensive working table in its category: 157 x 93 inches

- Complete protection against rust: the structure is manufactured in hot galvanized steel, while the work tank is in stainless steel

- Installation dimensions are the smallest in this category: the machine takes up just 393 square feet

- Slab loading operations made easier thanks to the tilting table with an off-the-ground height of just 15 inches