Baca Systems

Waterjet Technology

A leader in waterjet technology for 30 years, Baca Systems offers the FlexJet, a 5-axis waterjet system for processing ultra-compact materials. FlexJet offers traditional 60k high pressure or optional 90k ultra-high pressure for faster travel speeds. The system can cut inside miters/arcs up to 60 degrees and offers the fastest speeds in the industry for processing ultra-compact materials. Baca Systems also offers the Robo SawJet system – the most reliable and compact cutting solution in the industry. Robo SawJet produces the highest yield and highest production capacity by combining the speed of saw cutting with the flexibility of abrasive waterjet.

Beckart Environmental

Water Recycling System

Designed for 100% water recycling and closed-loop operation, the Hy-Pack® system from Beckart Environmental filters influent from saws, polishers and CNC equipment down to below one micron, and routes the clean water back for use in the fabrication process. These fully automated systems include company-engineered PLC control panels, and fabricators deal directly with the manufacturer throughout the planning, installation and support phases of all critical equipment. They are available in 10 GPM to 200 GPM sizes, and all systems are backed by a factory-trained network of regional support technicians for years of reliable service.

Braxton Bragg

Saw/Cutting Machinery

The Fab King Fabrication Center cuts sink holes, profiles edges, drills holes, polishes backsplashes and antiques, polishes or hones surfaces.

Like a Swiss Army knife for your shop — The Fab King combines the functions of a router, a drill press, an in-line backsplash polishing machine, top polisher and a radial arm sink cut-out machine in one.

Real world designed — nobody knows a machine like a repairman. The designer of this machine has more than 20 years’ experience in the stone industry. Much of that time was spent trouble shooting and repairing stone equipment. 220-volt, single-phase power and off-the-shelf components guarantee maximum uptime.

The Fab King Fabrication Center has a quick set-up and doesn’t have a long training program.

CMS

CNC Stoneworking Machinery

The Aquatec is the most exciting new addition to CMS’s line of CNC machinery for the stone fabrication industry. This machine is equipped with the most advanced 5-axis waterjet head in the business. Utilizing IKC kerf compensation technology, every cut comes out at the exact angle that it has been programmed to be. This machine can produce perfect miters that are ready to glue and true perpendicular cuts to make downstream edge finishing a breeze. Paired with CMS’s new servo powered Green Jet intensifier pump this machine takes stone machining to an entirely new level.

Co.Fi.Plast

Saw/Cutting Machinery

Co.Fi.Plast and Wires Engineering Group designed and developed the Easy 11, a new generation of multi-wire cutting machines for processing versatile combinations of thin and thick slabs.

The Easy 11 multi-wire machine loads a maximum of 11 diamond wires and is equipped with a patented system for the positioning of removable spacers for the setting of the cut thickness from ¾ inch up to 6 inches without dismantling any wheels.

Co.Fi.Plast diamond wires for slab thickness applications are usually 7.3 mm in diameter, but the machine can also be fitted with 5.3 mm and 6.3 mm.

The manufacturing flexibility offers different variations (36, 37 or 40 beads/meter) and diamond bead types. Thanks to its U.S. branch in South Dakota, Co.Fi.Plast is strongly active on site, offering technical support and guiding the customer in the selection of the best cutting parameters and diamond wire typology.

Comandulli

Edging Machinery

Combining precision craftsmanship and a compact design, along with the durability and performance that have made Comandulli famous, the Omega Pencil features two individual calibrators at the top and front of the machine that square off the edge before profiling, plus 11 oscillating heads that provide a fast and smooth polish. The result delivers unrivaled speed and productivity, even for today’s most demanding and sought after designs. This includes up to 3 feet per minute for pencil edge profiles. Of course, the Omega Pencil also offers more traditional profiles such as straight, edge, round, bull nose, shark nose, half bull nose and quarter bull nose — all at the same exceptional quality and speed. What makes this machine even more impressive though is its friendly and easy-to-use touch screen. Groups are set automatically and programs and parameters are saved in a folder for easy recall when needed. For more information on the Omega Pencil, contact Comandulli North America.

Continental

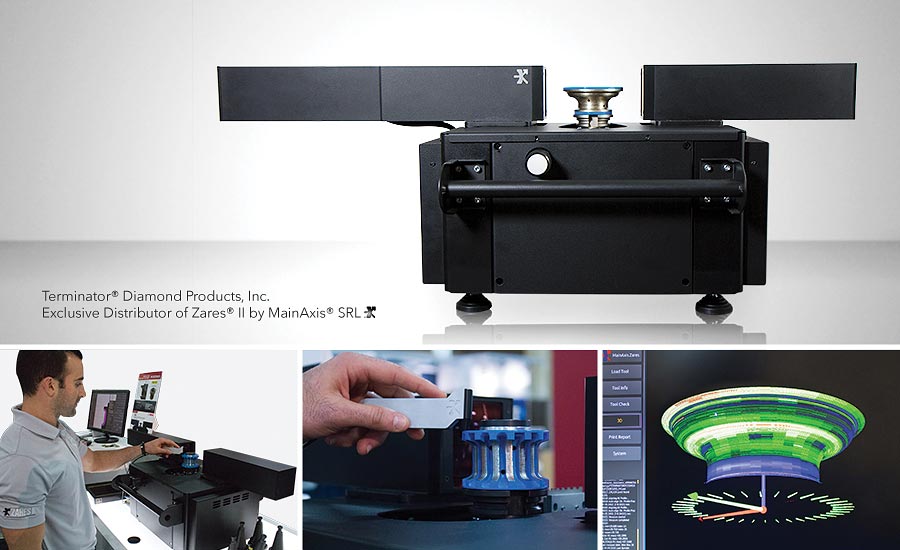

Complement to CNC Machinery

Zares®II 3D Optical Tool Measuring System CNC tool calibrations of new or existing tooling is an extremely tedious and costly task. This process is time consuming, yields inconsistent results and halts production. The costs can exceed thousands of dollars in premature tool wear and lost production each month. Zares®II provides the solution and final piece to complete your automated CNC production process. With features such as:

- Ability to measure all manufacture tooling — ADI, Tyrolit, Nicolai, Diamut, & others

- Software which integrates directly to CNC machines – CMS Brembana, Breton, Intermac, Northwood, Park Industries

- Measure any profile in seconds 100% offline — calibrate a 7-position tool set in 10 minutes

- AutoAlign feature automatically aligns new and used tools

- Ability to preview what your stone edge will look like before tooling has ran

- Reports – concentricity, tool consumption, 360° 3D tolerance scan and much more

Ebbco

Water Recycling System

Ebbco Inc. of New Baltimore, MI, announces the release of the newly redesigned Automatic Hurricane Filter Cleaning Station. The Automatic Filter Cleaning Station offers hands-free cleaning in minutes on Ebbco Brand Hurricane Filter Cartridges that provide crystal clear water to CNC and edge polishers. Filters are placed on automatic rotating rods and water is distributed from the existing filtration unit to a series of nozzles designed to clean each individual pleats. Stone sludge removed from the filter is then deposited into an easy-to-remove patented Settling Weir bag. Excess water returns to the pit for further filtration. A spray down nozzle is also included to clean up any excess sludge left in the collection tray. Ebbco Inc. also offers a series of stone filtration systems custom designed to fit the needs of each individual shop.

Gmm

CNC Stoneworking Machinery

The Gmm GL5 Multispindle CNC cutting center is equipped with five independent cutting heads for cutting dimensions from 140 mm to 2000 mm and blades from 400 mm to 520 mm in diameter.

THK linear guides and skates, Girard gearboxes and Natbesco planetary box are the top names involved in the GL5 CN 2 (patent pending) machine construction. Extreme precision cutting results due to the rotating top cutting unit and the fixed cutting conveyor belt.

The Gmm dedicated software developed by the Gmm Automation R&D team with automatic nesting of the cutting piece with defect track and the external offline camera which can be operated during the cutting process, secures a large production result up to 420 square meters in eight hours. A cutting production report is automatically provided.

Hypertherm

Waterjet Technology

Hypertherm HyPrecision waterjets are engineered using Advanced Intensifier Technology (AIT). By rethinking the way the intensifier pump works, we were able to make it work harder, last longer and require less service time. AIT is what makes Hypertherm HyPrecision waterjets more cost effective.

- Easier

- Longer lasting

- Streamlined

- Optimized shifting

- Simpler high-pressure

- Prolonged seal life

Hypertherm also built the most robust information tools in the cutting industry. From responsive waterjet experts working the customer service lines, to mobile applications and 24/7 online technical service guides, Hypertherm provides what you need to know. And we offer it to our customers free of charge.

Information is only good when you have it. Be informed, be connected and stay ahead of profit-losing troubles and delays with insights from Hypertherm.

Intermac

Waterjet Technology

The Primus 322 is a complete waterjet cutting system available in 3-axis or 5-axis, along with a single or dual head. This feature-rich machine comes equipped with a stainless steel tank that is unique to the industry and protects against rust. With standard proportional control, the possibility of mechanical shock is eliminated and garnet flow is carefully regulated to prevent waste. This is vitally important as garnet represents 40% of the total cost in operating machines with the high-abrasion process.

Omag

CNC Stoneworking Machinery

Omag S.p.A introduces its latest in its range of CNC work centers and the latest in countertop, architectural and dimensional stone-processing machinery, the Blade5ar. The Blade5ar is particularly useful for deep cutting, milling, shaping and polishing of countertops, large dimensional pieces and architectural stone.

This machine, along with Omag’s wide range of shaping and routing machines, can be featured with:

- Single or dual-table configurations

- Lathe attachment option

- Tables in movement

- Automatic blade change

- Automatic tool change (tool changers of many different sizes)

- Optimization of cutting

- Combination of cutting and drilling on the corner

- Automatic vacuum manipulator system

- Ability to work with material in small to large size ranges

Park Industries

CNC Stoneworking Machinery

The Titan® CNC router by Park Industries routes, shapes and polishes stone while delivering lower costs and maximum uptime. What truly sets the Titan® apart is its effect on your bottom-line. It has the potential to increase your capacity by up to 102%. With faster machine movements, more work gets done. Park’s Integrated Tool Management™ system extends tool life by up to 50% by monitoring, measuring and compensating for tool wear. This dependable system significantly reduces the need to reshape your tools, saving you thousands of dollars in tooling costs. Learn more about the Titan® on our website.

Poseidon Industries

CNC Stoneworking Machinery

Poseidon Industries has quickly become a leader in developing intuitive versatile machines focused on making the fabrication process more efficient. The Poseidon Industries T-Rex 5 combination 5-Axis CNC bridge saw and 4-Axis CNC router is the most useful machine on the market. The T-Rex 5 can easily double your production capability with the ability to cut a full slab in under 20 minutes. When you combine intelligent design and a heavy-duty structure, the T-Rex 5 does everything you need to completely finish a job on one machine, including cut full slabs, sink cut-outs, faucet holes, edge profiling and polishing. Truly reduce your labor with a machine that does it all. Some of the features include:

- Dual-Tool CNC cones built for high-speed tooling

- 14- to 20-inch blade for cutting slabs

- Dual-table and customizable work areas

- 30HP electro-spindle

Prussiani

CNC Stoneworking Machinery

Introducing the Tornado -- A revolutionary high-production full CNC-controlled router designed for optimum cutting and polishing of kitchen sinks and vanity bowls. All the functionality and quality of full fledge CNC routers, but without the hefty price tag and the large floor space of full size machines.

Key features of this unique design are:

- Quick workpiece positioning thanks to the Quickzero™ reference system

- Easy to program and operate -- one day training and ready to work

- Automatic Locking System (ALS) of workpiece in place -- no suction cups needed.

- Perfect polish due to the always true surface reference created by “ALS”

- Fast loading and unloading utilizing the roll-in roll out conveyor concept

- Hard center-line arrow to quickly locate the cut-out location

- Prussiani’s best warranty in the industry – three-year parts and labor included.

Regent Stone

Saw/Cutting Machinery

The Husky bridge saw by Rye Corp is used to cut slabs of granite, marble and all kind of stone slabs. The bridge saw stops at several points, comes with a 20-horse power motor and is trusted throughout the stone fabrication industry.

This saw combines simplicity and functionality to create a bridge saw that stands up to even the toughest jobs. Dimensioning granite for countertops and architectural cutting of stone. The Husky’s controls are easy to use and you can operate the saw using the control panel and the wireless remote at the same time.

Standard features include: heavy duty 6- x 10-foot tilting table that stops at 0, 450, 900 and 1350 with variable locking positions; precision machined gantry and bridge; 20 HP, 220v, three-phase direct-drive VEM motor and 18-inch diameter blade capacity. Miter cut capability. Water solenoid automatically turns the water on and off with the spindle motor; high-intensity laser and convenient control panel with amperage gauge and digital readout.

Salem Stone

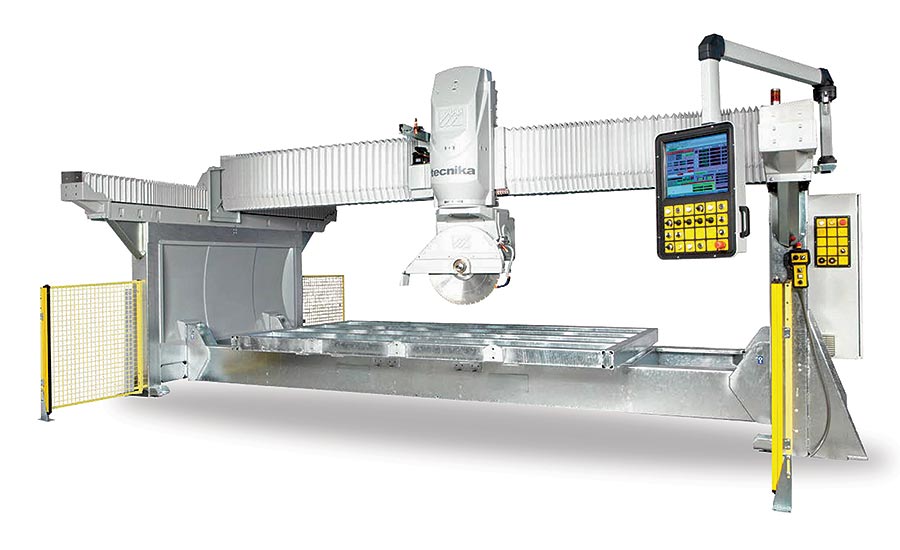

CNC Stoneworking Machinery

Salem Stone, partnering with Denver, delivers the first and most advanced multifunctional 5-axis CNC bridge saw – the Tecnika. This machine is a modern monobloc bridge saw with rotating and tilting head and hot zinc coated frame for exceptionally long-lasting sturdiness and anticorrosion. Equipped with an ISO-40 spindle that can hold both the blade and router bit or core drill and a manual quick release for easy tool changes, the Tecnika excels in a variety of applications, including multidirectional cuts, mitering, sink cut-outs, engraving, texturing, leathering and more.

Water Treatment Solutions

Water Recycling System

Water Treatment Solutions (WTS) pioneered the 100% closed loop, chemical-free, water recycling system for the stone industry. We are the innovators in producing both crystal clear recycled water at less than 2 micron and gray/white water at less than 25 micron. With over 800 systems installed across the U.S., Canada, Mexico, South America and the Islands, WTS knows that water is the backbone of your shop. In 2017, our customers will collectively recycle over six billion gallons of water. We are also dedicated to the well-being of your team — that is why we use no chemicals in our process and our system has the ability to capture the stone dust residue to such an extent that the air born silica dust is meeting and exceeding OSHA standards in WTS shops tested across the U.S.

Wilson Industrial

Saw/Cutting Machinery

The Wilson 11’6 Gantry Saw is built to last. Its heavy duty construction has proven to stand the test of time. New Mitsubishi touchscreens and automated controls make this saw a workhorse. Its various options include a variable speed drive for the arbor speed, operator weatherproof platform for outdoor installation, turntables and much more. For more information visit our website.