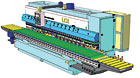

The LCR from Marmo Meccanica is a specialized linear polishing machine for flat edges that can process a pencil round profile in sizes up to 4 cm and chamfers up to 6 cm. It can round and polish the two corners of a flat edge as well as chamfering them at 45 degrees.

The LCR structure is composed of the following:

- 1 incoming calibrating/drip-sizing unit - adjustable both crosswise and lengthwise - to gauge the thickness of the material with varying depths (maximum 6 cm from the edge) or, rotated to the horizontal axis position, for dripstone cutting

- 7 mandrels for smoothing and polishing, the first of which equipped is with a mechanical stop for the diamond tool

- 2 upper and lower 45-degree chamfering mandrels for pre-chamfering diamond tools, equipped with a mechanical stop, which allows the unit to establish the pencil-round edges dimensions

- 2 groups of 3 mandrels each, counter-oscillating (mechanical stop on the first one of each group) for pencil round chamfers (maximum thickness of 4 cm) and 45-degree flat chamfers (maximum thickness 6 cm).

www.marmomeccanica.com