Welcome back to Part Two of this three-part series where we unravel, demystify and lay more pavers leading to the “New Frontier of Mineral Surfacing.” As a brief recap, in Part One, I detailed many of the leading questions fabricators have shared with me regarding the category; questions that have hindered more widespread and aggressive adoption to date.

I then shared various solutions to these questions as provided by the manufacturers and distributors making great strides to assuage the resistance. Then finally, I posed multiple teasers as to why a fabricator should consider, at the very least, active learning and their own R&D on the category.

Deep diving now into Part truly Two: Mineral surfacing has a solid value proposition story to tell and these values will necessarily fuel its growth. I deem the category a very strong player in and of itself, let alone a synergistic design relationship with the incumbent surfacing preferences. Mineral surfacing growth will systematically work its way through pricing normalizations, optimal applications and the methodical development of best practices; all of which we see unfolding more rapidly the past 24 months. Let us now peer into the demystifying of the category here in Part Two.

As the mineral surfacing category evolves and fabricators are becoming more comfortable with fabrication and installation techniques, manufacturers are rapidly vying for brand position, routes to market and differentiation. This “jockeying” of position can be see amongst many of the leading brands such as Lapitec, Neolith, Dekton, Sapienstone, Infinity, Laminam and Geoluxe, who are using descriptors for their brand in an attempt to differentiate, and in some cases, distance themselves from the name, “porcelain.”

Why distance from the name porcelain when it remains such a highly successful category of products and, other than natural stone, is certainly one of the oldest? Think, “brand equity.” Embedded in the heart of marketing is, “the story,” and when trying to bring a product to market amongst a wide field of strong companies, differentiation creates an opportunity for equity with the brand. It was expressed to me several times in my research that the immediate association with the name porcelain is an age-old product used to make vases, mugs and plates. Not that this is negative, but it is common.

Two strategies then: capitalize on the prevalent category awareness so there is less confusion and a greater comfort level when introducing a new product or, separate yourself from the pack and try to be something new, unique; blaze the market with “the next best thing.” As a result of the latter, descriptors such as pyrolithic, ultra-compact and sintered are being used, and while perfectly understandable, it does necessarily create confusion in the market, and actually, further supports the utility of a broad-based set of standards.

So we ask, what’s in a name? I say, while each of these countertop descriptions are intended to be endemic to a certain brand, the rest of the enterprise chain (dealers, A&D, builders, retailers, homeowners, etc.) remain confused; confused as to what is the difference when they all seem to tout many of the same installed benefits? And while the manufacturing processes and aesthetics are different amongst these various descriptors, in the end, there are several attribute commonalities with one KEY process to each that is a unifying factor: heating the raw materials to nearliquefaction – which is known as, “sintering.” This process is endemic to mineral surfacing and resides at the very core of what sets this category apart from all others.

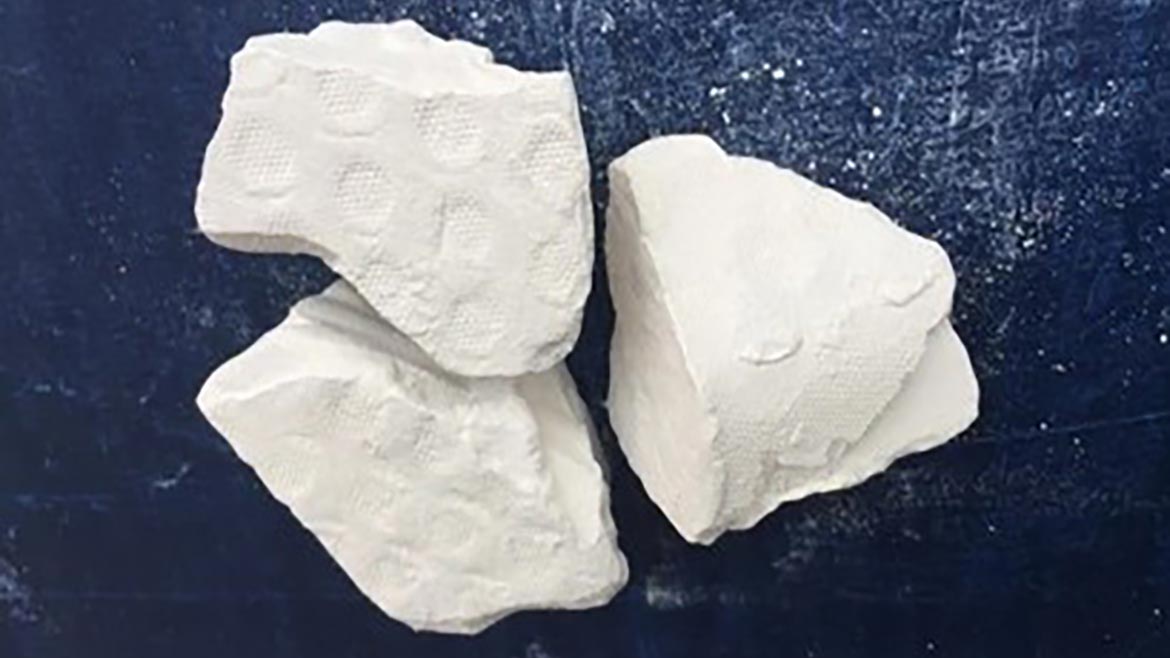

Sintering, in laymen’s terms, is essentially the super heating of the raw material mix to where there is a phase transition of the substrate: from a loosely bound mixture to a solid substance where the minerals have essentially fused. (See graphic 1.1)

The sintering process is what necessarily yields the highly desired end-product attributes, including: durability, thermal conductivity, UV resistance, impermeability to water, chemical and stain resistance and scratch resistance.

What is interesting, however, is the fact that while the raw materials experience a change in chemical bonding, they do not “melt” per se. There is a definite temperature limit that each of the brands will not exceed because in doing so, the mineral mix would reach liquefaction which would then phase transition again into vitrification, or essentially, making a highly glass-like product; something that would then diminish some performance properties when the intended target is a highly durable vertical and horizontal surfacing material.

Interestingly, it was only a few years ago the NSF (National Sanitation Foundation) changed their definition of “solid surface” and within the new definition resides the words, “homogenous core.” It is this fundamental product attribute that would make this category of products eligible for NSF 51 approval; the standard that speaks to Food Zone use/safety. And while there are standards for porcelain and ceramic out there already, this nomenclature quandary -- coupled with some proprietary elements embedded in some various brands’ processes -- would likely necessitate a new or broader standard created for this category of large-format, resin- and binder- free, mineral mix-based, super-heated materials.

Realizing this conundrum and to this specific end, one of the KEY results of my nine month national study was the birth and creation of the name “mineral surfacing”as it relates to unifying all of the materials we are speaking of here.

The two most apparent commonalities of these materials are the sintering process and a raw material mix of exclusively minerals (with no resins/binders) largely including, kaolin (see Fig 1.2) feldspar and sand (quartz).

Graphic 1.2. Photo courtesy of Max “Paul” La Pera

Now, since there was already great debate at the time where the makers of Lapitec® laid claim to being the “real” sintered materials and vehemently opposed being called a “porcelain” and competitor materials calling themselves, “sintered stone,” the need for a neutral identifier that would unify all the products was pressing. The goal of this neutral identifier was to reduce confusion in the market and to set a foundation to more easily pursue standards creation; all the while, none of the manufacturers would have to sacrifice or jeopardize their investment in branding and differentiation nor were required to use the new term.

I presented and subsequently offered my naming convention and complete thought process around “mineral surfacing” to the International Surface Fabrication Association (ISFA), since they are the leading industry organization focused on engineered surfacing. A vote of the Board of Directors ratified the use of my mineral surfacing name and reasoning, and has since devoted efforts to educate the market accordingly. As part of their mission to provide value to their fabricator base, ISFA now offers, “mineral surfaces training” somewhat regularly. These trainings focus on education, sharing best practices and hands on demonstration, all geared towards raising the comfort level and confidence of a fabricator to embrace the category.

It is important to reiterate, that individual brands need not necessarily use or incorporate mineral surfacing into their “story,” but for the sake of clarity, unifying like products, less confusion to the enterprise chain and for the eventual creation of standards, the name mineral surfacing serves a highly critical function to the industry.

Not surprisingly, several companies and brands have “adopted” the name mineral surfacing for their own use and use it to describe their products or some new off-shoots of existing products (including raw material reformulations), etc. I am honored these global conglomerates like the name so much they will use it, and while there is nothing preventing them from doing so, it necessarily mitigates the efficacy of its creation. Let’s just say, to be continued.

If you are a fabricator watching from afar and waiting for demand to necessitate your more mindful adoption, I may suggest to think twice -- that is, at the very least, be more proactive than reactive with this category. As a former fabricator, I was generally not a Gen 1 early adopter, with the exception of quartz surfacing. Back in 1998, when I learned of what this category was and its value proposition, I could not embrace it hard and fast enough and despite a couple years of “finding its way,” I was extremely successful with the product and category proliferation from day one and want to share some of the strategies I used. The simplest way is to remember the acronym, D.E.B.I.T.:Differentiate, Educate, Believe, Investment, Test. Therefore, before a customer “debits” their account to buy the product, you should have already, “DEBITed” them.

-

DIFFERENTIATE: I believe strongly in two sales values: #1) Do not speak negatively about a competitor (company or material) and #2) e.g., the best Mercedes salesperson is a good BMW salesperson. Regarding #1, when you speak confidently about how a product performs and accentuate how it is either different or superior in performance, you necessarily speak indirectly about the competition. Common sense perhaps, but all too often I hear direct attacks and I am much more about taking the high road and creating excitement and appreciation on the benefits versus creating distaste of what something else lacks – a wise consumer will derive this on their own and the former speaks to a higher integrity, in my opinion.

Regarding #2), one can fully understand the brand or material one prefers which makes you the most money, however, your knowledge of the competition’s pluses and minuses is your best artillery in your pitch/education, while serving to hone in on what is best for your customer and closest to their desires/goals. So while I do not condone using a comparative disadvantage directly in your story, you can always spin the benefit of the one material over the other in any number of ways. E.g., “Don’t buy quartz because it has resin and you cannot put a hot pot on top, it could destroy your counter beyond repair.” Instead, consider, that one of the greatest performance benefits of mineral surfacing is its superior heat resistance; and while most other materials advise against putting a hot pot directly on the surface, with mineral surfacing (or Brand xyz) you can have all the peace of mind you want because the product was engineered to offer this luxury. Use your own words and spin it as you like, the key here is no direct attacks; accentuate and highlight the competitive advantage and that will speak for itself.

- EDUCATE: Essentially focus on product properties vs. price. To say something is “expensive’ is HIGHLY personal and subjective. I will suggest that claiming something is expensive can stem from everything amongst: what’s in your bank account at the moment, to ignorance and lack of understanding of the product, to personal values of one characteristic over another and the list goes on. I will suggest eliminating ANY judgment on affordable or expensive in your story and go so far as challenging the customer as to WHY they perceive something as such. Focus on product attributes and differentiation and with full knowledge, then the customer can decide their personal value of what the material offers. Your education is absolutely critical however; speaking of UV stability (outdoor use or NO WORRIES if direct sunlight hits the countertops 12 hours a day in your kitchen design), sleekness of appearance (you can suggest a more modern or minimalist design); superior heat, chemical and scratch resistance; suggest this is the “new” next gen material as many like to have something new and different than their neighbor. This is education and education is compulsory to mitigate any preconceived notions on “expensive;” if the consumer does not understand the value of something they are buying, it will likely always be “expensive’ in their eyes.

- BELIEF: You MUST personally believe in the value proposition of the material. When you believe the material offers certain value and that value will benefit the end user, this is your confidence to represent the product. Notice I do not say “sell” – and while indeed you may be selling, I wanted to create some distance in the connotations of “selling” because at the end of the day, you do want to listen to your customer; see what they need, want and value most; clear up confusion in their minds; and get them the product that best fits their overall goals. By believing in the value proposition, you communicate verbally and non-verbally your confidence, and I dare say, people buy people as much as they do brand or product. Your confidence can install a sense of calm and confidence in the buyer and this is priceless.

- INVESTMENT: Countertops I argue are an investment, not an expense. Their value is depreciated over time – they generally will provide utility for many years and hence, when you break down a $ 4,000 investment over 10 years, e.g., for around $1.10 per day, less than the price of a cup o’ joe at Dunkin, you can have an incredible material to use, enjoy, marvel at and be happy that what you have selected really fits your lifestyle and desires.

- TEST: Do your own testing of the products. Try to stain them, freeze them, cut on them, leave them out in the sun, scratch them etc. Build you own empirically based opinions and speak from a position of strength and experience. This builds belief and confidence, but also allows you to build your story when representing this category to a potential consumer.

Here is a prime example of why education is critically important: It arms you with the ability to hear what is not said. Indeed, a client may speak from desire, influence and/or ignorance, but when you are fully educated, you can discern their intentions despite the words they may use. The end result is a customer for life who will sing your praises (best free advertising!) with then a fine fab and install, bringing their dreams to reality.

It is clear that the mineral surfacing category is expanding, maturing and capturing a growing percentage of the premium decorative surfacing market. With more and more dedicated solutions being offered to facilitate the handling and conversion of mineral surfacing, fabricators, designers, retailers and specifiers are all buying in.

Part of the maturing process for the category sees a steady demystifying of “what” it is and what the benefits are. Understanding that the generic sintering process is endemic to the large-format product, manufacturers remain free to differentiate however they can while the enterprise of stakeholders can now understand that mineral surfaces is a catch-all name and can begin to specify according to aesthetic, function or both.

In January, we will run Part Three in this series on mineral surfacing. It will be rich in practical information on attributes, uses, strategies and touch on the how’s and why’s of strategic inclusion into the fabricator product mix. We will also touch on some new developments into the strategic use of manufacturing process technology to create further differentiation. It will be a grand finale to this particular series, the rate of change, advancements and improvements will necessarily require a revisit. Part Three is a must-read, and like a drawstring, pull the whole series together in an informative and exciting climax.