Stone fabricators rely heavily on machines to meet their customers’ needs. Selecting the right equipment is crucial for shops, whether they are just starting out or looking to upgrade from existing machines.

A hot discussion among stone fabricators is which machine is better…a CNC saw or a CNC sawjet? And the answer is…it depends. Both machines offer a ton of production capabilities, but what is right for you depends on your situation.

To help you make the best decision for your shop, we will explain the key differences and strengths of each machine type and compare CNC saws vs sawjets.

What is a CNC Saw?

The basics: a CNC saw allows fabricators to program a layout and let the saw cut it out automatically using computer numerical controls (CNC). Stone cutting CNC saws are a popular choice for countertop fabrication and can perform cuts cleanly, quickly and efficiently.

A CNC saw, especially a 5-axis one, utilizes its blade for straight cuts, miter cuts, straight line profiling and even some arc cuts. For sinks, faucet holes and radius parts, it uses tools and bits with its spindle.

With these milling capabilities and innovative features, CNC saws can perform nearly any cut and offer tight nesting. They are an excellent choice for your first CNC machine or when upgrading from a bridge saw, as they also offer manual cutting capabilities.

What is a CNC Sawjet?

You can think of a CNC sawjet as an upgraded version of a CNC saw. Both use a saw blade for straight and miter cuts, but instead of using a tool bit for sinks, tight nesting and radius cuts, a sawjet uses its precision waterjet. This is the key difference between sawjets and saws. The waterjet cuts faster, tighter and with more precision than a tool.

CNC sawjets, are typically considered the “crème de la crème” when evaluating cutting solutions. They offer the highest level of production, and with that, are a higher initial investment than a CNC saw.

With the waterjet’s ability to make any cut without worry of running into parts, CNC sawjets allow for faster finishing on CNC routers or significantly less hand fabrication. Sinks are the number one time saver on a sawjet. A sawjet can enable a shop to take on more jobs, including large commercial projects or complex custom projects, thanks to its waterjet capabilities.

CNC sawjets offer the highest level of production, and with that, are a higher initial investment than a CNC saw. Photo courtesy of Park Industries

Comparing Your Options

You know you want to cut with a CNC machine… now the question is which one?

Both machines offer excellent blade cutting, are extremely accurate and slice through a variety of materials like quartz, granite, quartzite, porcelain and more. The key differences in performance are production speed and material yield. These really come down to tool versus waterjet. See why in the example below.

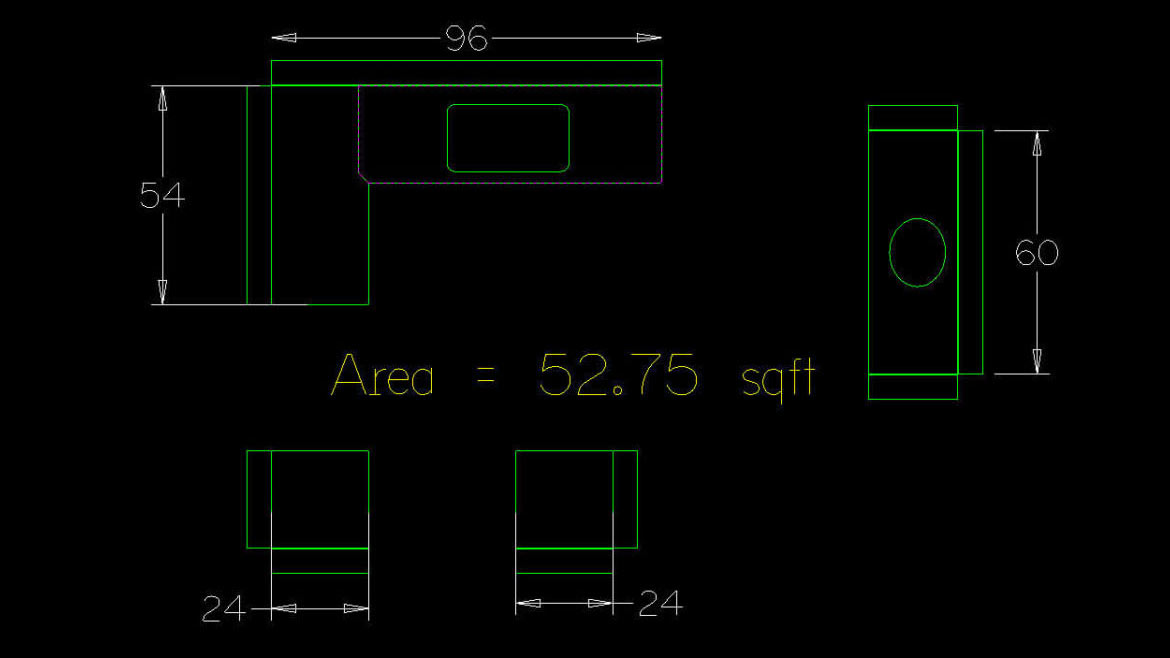

Example A: Common Kitchen Layout (52.5 Square Feet) Photo courtesy of Park Industries

Example A Scenario: CNC Saw

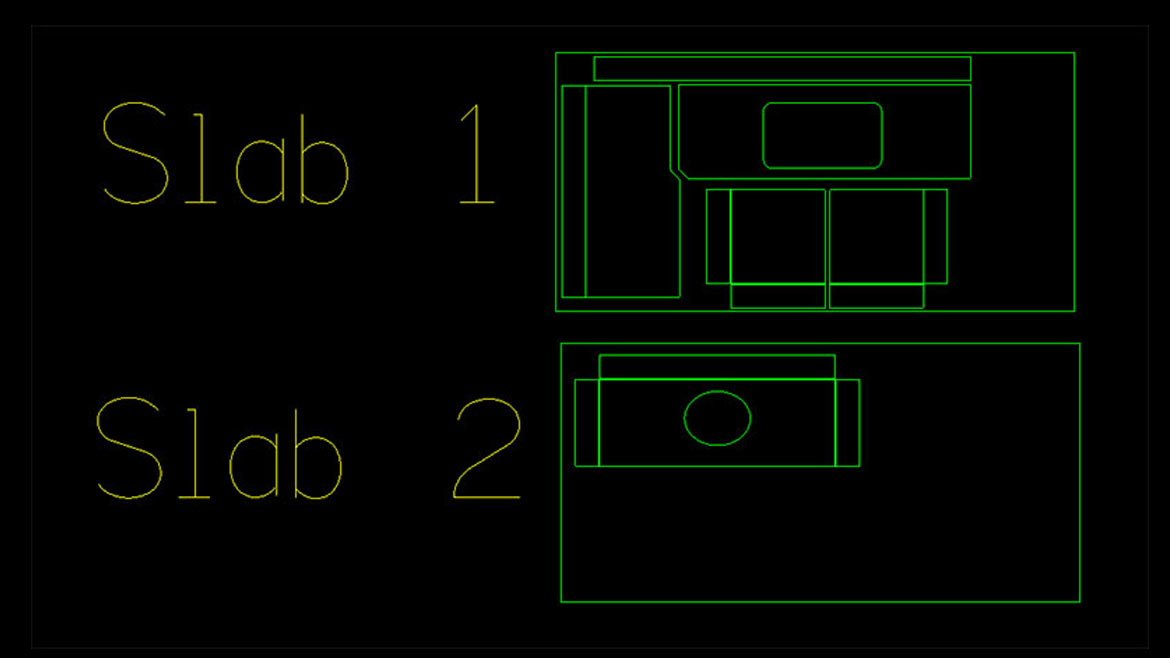

A CNC Saw cuts this example well, but the multiple sinks and tight nests increase its time to about 58 minutes and require two slabs. Here’s a preview of what the CNC saw program might look like, with two slabs needed.

CNC saw programs for Example A Photo courtesy of Park Industries

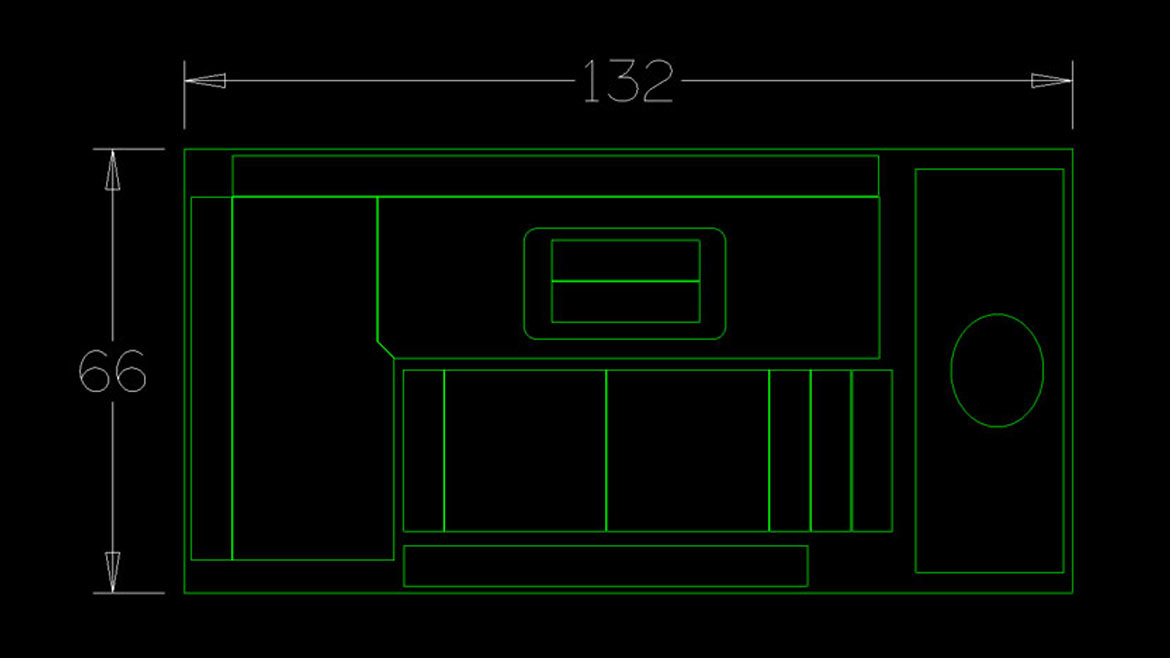

Example A Scenario: CNC Sawjet

A CNC sawjet allows you to breeze through this example, cut this program in about 25 minutes and needing only one slab. Below is a preview of what the program of a CNC sawjet might look like, tightly fit onto one slab.

CNC sawjet programs for Example A Photo courtesy of Park Industries

Investment

With an example like this, you may be thinking to yourself, why wouldn’t you choose a CNC saw? The CNC saw has one distinct advantage over a sawjet -- cost. A CNC saw comes in at nearly half of the monthly payment, along with less operational cost and consumables due to no waterjet system. A CNC saw may be a better option for shops that need lower initial investment and want to keep things simpler.

Saw vs Sawjet: Verdict

Most fabricators would agree that a sawjet is the higher production choice. If upfront cost is not a factor and you have the demand to warrant a sawjet, you can be confident choosing this option. Factoring in materials and labor saved with a sawjet, it offers excellent return on investment (ROI).

However, if you are new to these digital fabrications, still use stick templates or only produce a handful of kitchens a week, a CNC saw will offer plenty of cutting production and easily meet your needs. The best way to determine your needs is by answering a few key questions:

- How much money can you save in labor with a sawjet?

- How much money can you save on materials with tighter nesting?

- Does your chosen solution allow for growth?

After answering these questions, you will need to determine if the sum of these savings offset the added cost of a sawjet. If you are still undecided, the best thing to do is consult an expert.

.jpg?1657041008)