(This picture and the next) Based in Atlanta, GA, and operating in three states, Construction Resources, Inc. has multiple fabrication facilities, and it also supplies a broad range of building materials.

Over the past few years, countertop fabricators across North America have expanded their business into sectors such as tile, sinks, fireplaces and even cabinetry in order to provide a more complete buying experience for their customers. However, this concept has been taken to a new level at Atlanta, GA-based Construction Resources, Inc., which offers a range of building products that is unparalleled in the industry.

The company’s fabrication shops include Atlanta Kitchen in Decatur, GA (with three showrooms in the Atlanta area), Florida Bath & Surfaces in Santa Rosa Beach, FL (with a second showroom in Tallahassee, FL), and Innovative Surfaces in Pelham, AL.

In addition to processing and installing natural stone, quartz and solid surface countertops, the company provides installation of porcelain, ceramic and natural stone tile, frameless glass shower enclosures, shower doors, bath hardware, whirlpool tubs, cultured marble vanity tops and elements such as blinds, fireplaces and gas logs. For residential exteriors, Construction Resources can supply wood and vinyl shutters, garage doors, carriage doors, garage door openers, gutters and custom chimney shrouds.

In addition to the stone fabrication facilities, another division, National StoneWorks, imports pre-fabricated cut-to-size stone and tile for commercial applications. “We used to be primarily involved in high-rise and multi-family projects, and now we are doing a lot of apartments and hospitality,” Hires said.

All of the various companies fall under the Construction Resources umbrella. “When we get a customer or a builder into our showroom, we try to bundle products and offer a value-added service of them dealing with one source,” Hires explained. “It helps on the builder side in terms of contracts and on the retail side, where a homeowner only has to write one check. We provide countertops, cultured marble, glass, marble, screens, locks, garage doors, bathtubs, tile, and we just started a new carpet/hardwood division. We are not concrete, sheetrock or lumber, but focus on specialty items.”

The Atlanta facility also has two CMS/Brembana Maxima CNC stoneworking centers.

Fabricating operations

The Atlanta Kitchen facility works in all aspects of fabrication of stone, solid surface and quartz, and it supplies large production builders, commercial projects, millwork houses, military, as well as Big Box retailers.“Our entire facility is under crane,” Hires said of Atlanta Kitchen. “We have four overhead bridge cranes on two separate sets of rails and an independent indoor slab gallery with three bridges in a separate building. There is a 10,000-square-foot showroom, and a 10,000-square-foot slab gallery for exotics, also under a crane. We warehouse 750 to 800 slabs in the indoor gallery, and also have an outdoor yard for 2,000 slabs. We are also the Cambria Lexus partner for the area, so we inventory 400 to 500 Cambria slabs. Granite is about 50 to 60% of total sales, and quartz is 25 to 30% - mostly Cambria. The remainder is Solid Surface, Heritage Wood, Artisan Stone Collection Marble, Saratoga Soapstone and Stainless Steel Tops.

In Atlanta, slabs are cut using four Marmo Meccanica HTO 1B bridge saws from Italy. Advanced cutting is also done using a dual-table Flow waterjet with a 100-horsepower pump as well as a Northwood 257 Double Table SawJet, which is among the company’s latest investments. “We have had very good success with [the waterjet.] I like it a lot,” Hires said. “We also have a single-table version in Florida. The larger pump is great for 3-cm material. I love the versatility of it. We do a lot of 6-cm and 9-cm lamination and miter folds for commercial work. Without the waterjet, we couldn’t do them in a cost-effective manner.”

A Comandulli Synthesis line polisher from Italy is used for automated polishing at Atlanta Kitchen.

At Innovative Surfaces in Alabama, equipment includes two Marmo Meccanica bridge saws; a CMPI edge processor from Italy; a Marmo Meccanica LCV polisher and a Prussiani CNC stoneworking center.

The Florida Bath & Surfaces facility in Santa Rosa Beach features two Marmo Meccanica HTO bridge saws; a single-table Flow waterjet; a CMS/Brembana Maxima CNC stoneworking center; a CMS/Brembana Speed 3 CNC stoneworking center; and a Marmo Meccanica LCV polisher. “Our Florida operation is managed by our partner in Florida Bath, Bob Schoen, who services the Panhandle into Tallahassee,” Hires said.

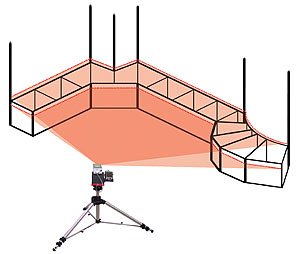

A range of templating methods is used at the company. “We have a Faro arm for digitizing, we have three LT-55 laser templating systems [from Laser Products of Romeoville, IL], and we also do some traditional templating,” Hires explained. “It really depends on the job and who is doing it. Some of the older people still do manual templating. We run two plotters as it is, so there’s no reason to force people to do that. There are some jobs that need to be stick templated.”

Overall, Construction Resources has 250 workers in three states, with 100 employees in Atlanta.

Overall, Construction Resources has 250 employees in three states, with 100 workers in Atlanta. “We try to cross train as much as possible,” Hires said. “Our fabricators fabricate, and our polishers polish, but we like the machine operators to be able to work the CNC, waterjet and bridge saws. We also cross train programmers. From an installation standpoint, one of the good things of us being slow was that our templaters cross-trained. It is a big advantage as we start to grow back, and it offers good customer service. Some of our templaters can do repair and light installs. We have had to travel further distances to find work - Augusta, Macon, Savannah and Columbus in Georgia - so it is an advantage when we can send someone out who can do more than one thing.”

When hiring employees, Construction Resources brings in a mix of experienced workers as well as staff members that require training. “It depends on the position. There are some things that we prefer to train from scratch,” Hires said. “I always need experienced CNC programmers. You don’t find them everywhere. We prefer experienced installers, but then they have to learn from us. From an employer standpoint, we found some good people over the last few years that we might not have found in a different economy.”

Considering the volume of Construction Resources’ business, the company’s ownership plays close attention to the amount of building permits issued. “In 2006, we had 40,000 to 50,000 permits per year,” Hires said. “Then in 2009, the entire metro Atlanta area took out 4,400 permits, but we weathered the storm, as our revenue went down from $50 million to $30 million. I am happy to be here and be in a good financial situation. I think we have turned the corner.”

Slabs are cut at Atlanta Kitchen using four Marmo Meccanica HTO 1B bridge saws from Italy.

A range of templating methods is used at the company, including stick templates, which are placed directly on top of the slabs.

The company also has three LT-55 laser templating systems from Laser Products of Romeoville, IL.

Among the many building products inventoried at Construction Resources, the company has a large collection of sinks.

Atlanta Kitchen’s indoor slab gallery warehouses 750 to 800 slabs and it also has an outdoor yard for 2,000 slabs.

Serving the Birmingham, AL, market and beyond, the company’s Innovative Surfaces facility is located in Pelham, AL.

Equipment in Alabama includes a Prussiani CNC stoneworking center.

Two Marmo Meccanica bridge saws are also in operation at Innovative Surfaces in Alabama.

The Florida Bath & Surfaces fabrication shop is located in Santa Rosa Beach, FL.

Among the equipment in the Florida facility, the company operates a CMS/Brembana Maxima CNC stoneworking center and a CMS/Brembana Speed 3 CNC stoneworking center.

Florida Bath & Surfaces operates showrooms in Santa Rosa Beach as well as Tallahassee, FL.

About the Artisan Group

Construction Resources is a member of the Artisan Group, a national organization of independent granite fabricators that have joined together to offer the Artisan StoneTM Collection, the first and only brand of granite wholly owned by Artisan Group, which has a comprehensive lifetime warranty. The group also offers Heritage WoodTM countertops and Kohler® sinks and faucets.Mitch Hires, Co-Owner of Construction Resources, serves on the Board of Directors for the Artisan Group, and he said membership offers a range of benefits. “Not only are they a great group of guys, but it has been a great learning tool for me,” he said. “There are a lot of guys in this group who have been doing this a lot longer than I have. I never managed a downturn. I was used to 30 to 50% growth, and having a group like that to talk to and learn from has been very helpful. Also, there is only one Artisan member per territory, so you don’t have competition, and there is a complete free exchange of information. Single sourcing from AG&M is another great benefit.”

Mitch Hires also serves on the Cambria Board of Directors. Mitch Hires and Sonny Hires Hires are also on the Atlanta Home Builders Association Board of Directors.

Construction Resources Atlanta Kitchen, Decatur, GA/Innovative Surfaces, Pelham, AL/Florida Bath & Surfaces, Santa Rosa Beach, FL

Type of work: processing and installation of natural stone, quartz and solid surface countertops; supply of a vast selection of interior and exterior building materialsStoneworking Machinery (Atlanta Kitchen): four Marmo Meccanica HTO 1B bridge saws from Italy; double-table waterjet from Flow International of Kent, WA; Comandulli Synthesis line polisher from Italy, two CMS/Brembana Maxima CNC stoneworking centers, manufactured in Italy, including dual-table and single-table models; a CMS/Brembana Maxima Speed 3 CNC stoneworking center; two Marmo Meccanica LCV polishers; a Thibaut radial arm polisher from France; and EnviroSystem from Water Treatment Technologies of Hampton, NH Northwood 257 SawJet

Stoneworking Machinery (Innovative Surfaces): two Marmo Meccanica bridge saws; a CMPI edge processor from Italy; a Marmo Meccanica LCV polisher and a Prussiani CNC stoneworking center from Italy

Stoneworking Machinery (Florida Bath & Surfaces): two Marmo Meccanica HTO bridge saws; a single-table Flow waterjet; a CMS/Brembana Maxima CNC stoneworking center; a CMS/Brembana Speed 3 CNC stoneworking center; and a Marmo Meccanica LCV polisher

Templating Equipment: three LT-55 laser templating systems from Laser Products of Romeoville, IL; Faro arm for digitizing

Number of Employees: 250 (in all facilities)

Production Capacity: 3,000 square feet per day (in all facilities)