The main goal of the project was to “represent the diversity and richness of various regions and cultures of Texas,†said Paul Adams, project manager of Wilson & Associates of Dallas, TX -- the project's interior architectural design firm. In regard to the size of the resort, he responded by saying, “Think Texas size -- imagine the largest hotel you've ever seen and double it.â€

In order to create this Western feel on such a large scale, it was essential to select the right building materials. Various types of marble, granite and limestone were key design components for the interior spaces. The material came from many sources, including International Granite & Marble (IGM)'s facility in Dallas, TX, which supplied more than 20 different types of stone.

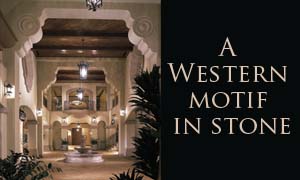

Italian honed and lightly polished Dore Reale marble and Murgiano marble decorate the lobby floor, and it is complemented by two varieties of limestone for the vertical applications. Lueders Antique limestone with a smooth finish was employed for the wall bases and corbelled column bases, while Lueders Rough Back limestone with a natural cleft finish forms the main portion of the lobby walls and arches. “The stones were chosen for durability and consistency of color due to the size and scale of stones used,†said Adams, adding that Mezger Enterprises Inc, of Lampasas, TX, supplied the limestone.

Additionally, the lobby features polished Emperador Light and Dark marble, which was quarried in Spain. The lighter shade was used for the concierge desk and bellman counters as well as a mosaic floor inset. Emperador Dark was employed for the front reception desk. The desk was accented with pieces of Inca Gold limestone with a honed finish that was quarried in Pakistan.

Another noticeable characteristic of the lobby is a marble mosaic of Texas' state symbol, the Lone Star, which was cut and implemented by Tesserae Mosaic Studio, Inc. of Plano, TX.

Among the many other impressive architectural details within the resort is a 330- x 30-foot-long walkway leading to the convention center. It is comprised of 20,000 square feet of 24-inch squares of Antique Gold from Egypt -- supplied by IGM. According to Adams, this is significant because tiles are typically no larger than 18 x 18 inches for a thinset installation. “Antique Gold was selected because it looks like limestone, but is harder, and wouldn't break as easily in this application,†he explained.

Moreover, the resort also features the Mission Plaza -- complete with two varieties of Mexican stone, which create a rich warm feel in the space. The floor border, column bases and stair nosing are made from Adoquin Stone, while the fountain -- the focal point of the room -- is clad in smooth Cantera stone.

The use of stone continues into the eateries, where Juparano Dourado granite with a polished finish -- quarried in Brazil -- dresses up the countertops and bar top in the Old Hickory Steakhouse. Further enhancing the décor is a floor comprised of African Multi-Color slate with a natural cleft finish.

Another area of interest in the establishment is Gaylord's signature glass atrium, which is a prime example of using several building materials in a design to achieve the desired look. “When you walk through the lobby, the atrium space transitions from real stone to faux stone,†said Adams. “Such an exceptional job was done at blending the two, you can't even tell where one stone ends and the other begins.â€

Making the selection

When it came to selecting the numerous amounts of stone for the project, the architect explained that the design team was challenged by trying to get the approval of a suitable range of materials without an excessive cull rate. “The samples we are given don't always represent the full range of materials,†Adams said. “We took the mock-up of the color range of materials, and eliminated the percentage of colors not desired. With such an exceptional team, we were allowed to be selective about the range and really get what we wanted out of it. Mezger and their installers did an exceptional job of reducing the percentage of undesirable colors in the lobby. We were very lucky. Everyone on board had a common goal for the project, which made it so successful.â€Working with such a large supply of stone to coordinate, IGM also faced challenges during the project -- in particular, regarding delivery time. “We had a ton of problems trying to get stuff in on time,†said Frank Hardwick of IGM. “Then, there were some things that came too quickly, so we had to worry about storage. Egypt was a challenge because the stone wasn't shipped directly to the U.S. It was shipped from Egypt to Israel to Spain to Houston. It took about two months just to get it.â€

Among the material supplied by IGM was 8,000 square feet of various colors of Chinese granite, including New Roman Gold, Atlantic Green and Tiger Skin, which were used for each of the 8-foot-long vanity countertops featured in the guestrooms and suites, according to Hardwick. Crimson Red granite from India was also used for the guestroom vanities.

A majority of the 200,000 square feet of stone that was supplied was in the form of 12- x 12-, 24- x 24- and 36-x 36-inch tiles, which were featured throughout the public areas and guestrooms of the resort.

In addition to the stone supplied by IGM, a number of other suppliers were involved with the construction of the Gaylord Texan Resort & Convention Center. Polished Giallo Provenza marble was supplied by Stone Quarry, Inc. of Dallas, and was used for the guestroom entry floors. Walker Zanger's Dallas office provided some of the other stones. Some of the custom-cut materials were specially fabricated overseas, and others by Sigma Marble and Granite Inc. of Dallas, TX, which was also the installer for all of the stone utilized in the project.

Installing the stonework

According to Robert Harris of Sigma Marble and Granite Inc., implementation of the stonework took approximately one year using mud set and thinset installation methods, with about 35 workers on the job at any given time. Harris said the only real difficult aspect of the job was the sheer magnitude of the project. “There was so much going on at one time,†he said.Construction began in June 2001, and according to Adams, since opening, the Gaylord Center has received rave reviews. “The hotel brought a lot of prosperity to the area,†said the architect. “Over 2,000 jobs were awarded, and it is conveniently located near the airport. People comment on the exceptional stonework job in the lobby.â€

The resort also features a 25,000-square-foot spa and fitness center, which contains an indoor pool, a golf course and water sports nearby.

End box

Gaylord Texan Resort & Convention CenterGrapevine, TX

Interior Architect: Wilson & Associates, Dallas, TX

Exterior Architect: Hnedak Bobo Group, Memphis, TN

Stone Suppliers: International Granite & Marble (IGM), Dallas, TX; Stone Quarry, Inc., Dallas, TX (Giallo Provenza); Walker Zanger, Dallas, TX

Custom Mosaic Supplier: Tesserae Mosaic Studio, Inc., Plano, TX

Stone Supplier/Installer: Mezger Enterprises Inc., Lampasas, TX (Lueders limestone)

Stone Installer/Fabricator: Sigma Marble and Granite Inc, Dallas, TX