With 20 years of experience in the homebuilding

industry, Clark White decided to open Precision Stoneworks, a high-tech stone

fabrication business, in 2003.

For years, Clark White focused his efforts on servicing new homebuilders, but in 2003 he decided to take his business a step further by opening his own fabrication shop, Precision Stoneworks, which is located in Lodi, CA. Since that time, the company has strived to operate a top-quality facility - complete with state-of-the-art equipment and green fabrication practices.

“I spent 20 years in homebuilding, and before I knew it, I was selling a lot of countertops without really trying,” said White, explaining the reason for establishing his own fabrication business. “When I started, I had no preconceived ideas of how to do fabrication. I sought out the best technology in the industry at that time, and I still believe it is right up there. We have three CNCs.”

Precision Stoneworks operates out of a 24,000-square-foot facility, which sits on two acres of land. “We are very centrally located,” said White. “I picked Lodi on purpose, because it is right in the middle of everything.” The company’s strategic location allows it to cover the entire Northern California market - from the Oregon border to Fresno, CA - in both the commercial and residential sectors.

The 24,000-square-foot shop is equipped with a lineup

of machinery from Park Industries of St. Cloud, MN, including a Fusion 4000

saw/waterjet CNC machine.

To meet its market demand, the shop consists of 10 workers and a line-up of machinery from Park Industries of St. Cloud, MN. “Park is an American manufacturer,” said White. “I like their level of service and their commitment to service quickly. They have a full lineup of machines. I wanted to deal with a reputable manufacturer.”

Among the Park Industries equipment used for fabrication are two Destiny CNC stoneworking centers, a Fusion 4000 saw/waterjet CNC machine, a Yukon II gantry saw and a Velocity edge polisher. “As technology goes in the stone business, we would be right up there at the top,” said White. “We used CNCs from the beginning.”

According to White, the quickness and precision of the

Fusion 4000 has increased production significantly. “One machine replaced about

three saws,” he said.

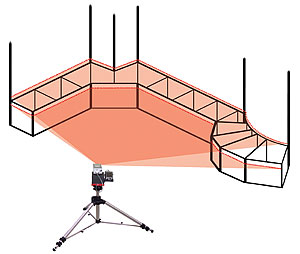

In addition to the shop staff, Precision Stoneworks also employs two full-time templators who use an LT-55 Templator from Laser Products Industries Inc. of Romeoville, IL. “We are all digital,” said Clark. “We never used sticks and glues. We utilize technology to the fullest extent. Digital templating requires not only embracing it, but it’s a significant investment.”

The waterjet capabilities of the Fusion 4000 allows

Precision Stoneworks to produce high-quality custom pieces.

And while production is important, safety remains a top priority for Precision Stoneworks. “The shop is as safe as can be,” said Clark. “We put a high premium on safety. We are a completely wet shop. We are committed to being a green fabricator. We don’t create dust. We own a closed loop filter system, and there is no dumping of water in the storm drainage.”

Additional environmentally friendly practices include recycling all scraps. “We give them to a road bed producer that grinds them,” said Clark. “There are many more green products out there now. We have embraced those things.”

The shop also houses a Yukon II gantry saw from Park

Industries.

Moreover, the company has looked for other outlets to expand its business during the economic downturn. “The new home segment is very quiet now,” said Clark. “We made up for it by expanding our opportunities by developing a network of dealers. We opened up kitchen and bath shops. We hope to continue to grow and expand. We are always seeking new opportunities.”

Two Park Industries Destiny CNC machines play a

critical role in the company’s production of approximately 12 kitchens a day.

Sidebar: Precision Stoneworks

Lodi, CAType of work: commercial and residential

Machinery: two Destiny CNC stoneworking centers, a Fusion 4000 saw/waterjet CNC machine, a Yukon II gantry saw and a Velocity edge polisher -- all from Park Industries of St. Cloud, MN; two LT-55 Laser Templators from Laser Products Industries of Romeoville, IL

Number of Employees: 10 shop workers, two templators

Production Rate: approximately 12 kitchens a day

In addition to the shop staff, Precision Stoneworks

also employs two full-time templators who use an LT-55 Templator from Laser Products

Industries Inc. of Romeoville, IL.

Additional Photos

A Velocity edge polisher is in place to finish the

edges of tiles and slabs.