Baca Pure Filtration System: Ebbco

The Baca Pure Filtration System is designed to remove stone particulate from water. A heavy-duty centrifugal pump is mounted directly over the floor pit, which incorporates a custom sweeper package to keep dirt from settling. Dirty water from the collection pit is delivered to the Cyclone Filtration System at the specified flow and pressure, water is polished down to 10 micron by a series of hydro-cyclones before entering a 2,600-gallon gray water holding tank. The Wizard System automatically injects a coagulant solution into the filtered water before entering the conical holding tank. The holding tank then overflows excess water back into the dirty water collection pit for continuous recirculation. All particles greater than 10-micron are deposited into a sludge hopper, lined with a heavy-duty disposable bag for easy disposal. The gray water delivery pump delivers the gray water from the holding tank to the entire shop at 75 psi. Optional Hurricane Filtration Systems provide point of use crystal clear water, which is cleaner than city water, as needed up to the established system flow rate.

Product Benefits:

- Reduce your water bill

- Recycle 100% of your shop water

- Upgradable as you grow

- Custom built for any shop requirements

- Provides constant water pressure to the entire shop

- Crystal clear water with “zero” downtime

- Manufactured in the U.S.A.

AIR FILTRATION SYSTEM: GRANQUARTZ

Fabrication processes produce dust and fumes that have been associated with impaired health which translates to decreased productivity. DuroTower from DuroAir efficiently collects these dangerous contaminants and fills the space with clean air from the system outlet. The DuroTower is a cost-effective air revolver system that is 10 times more energy efficient than traditional overhead dust purification systems. Flexible with multi-tower models that can be outfitted with casters for portability and environmentally compliant with air rotation technology that removes airborne particles down to one micron. The DuroTower reduces energy costs through the de-stratification of heat layers, homogenizing air from floor to ceiling to within five degrees.

www.granquartz.com

The HydroClear™ Pro Water Recycling System: Park Industries

The next generation of HydroClear Systems, the HydroClear Pro series by Park Industries, enables fabricators to better manage their water usage, which could translate to efficiency gains and a significant savings in water consumption costs. The HydroClear Pro series utilizes closed loop recycling to greatly reduce the amount of water used in your fabrication process, and less water means a positive impact to your shop and the environment. Features include:

- Six unique models that can be customized to meet your shop’s water needs.

- All-in-one design eliminating the need for a separate holding tank, saving precious floor space.

- Automated water system maintenance, reducing labor costs.

- Able to accommodate up to 170 gallons of water per minute to your shop.

- Reduces water consumption by up to 90% or more, and your water bill by nearly 70%.

- Many enhancement options available, including an Advanced Controller, pH Balance System, Bromine Sanitizing System, Second Stage Polymer Feed and more.

For the health of your equipment, your bottom line and the environment, the choice (and your recycled water) is clear. Transform the way your shop uses water with the Park Industries HydroClear Pro Water Recycling System.

www.parkindustries.com/hydroclearpro

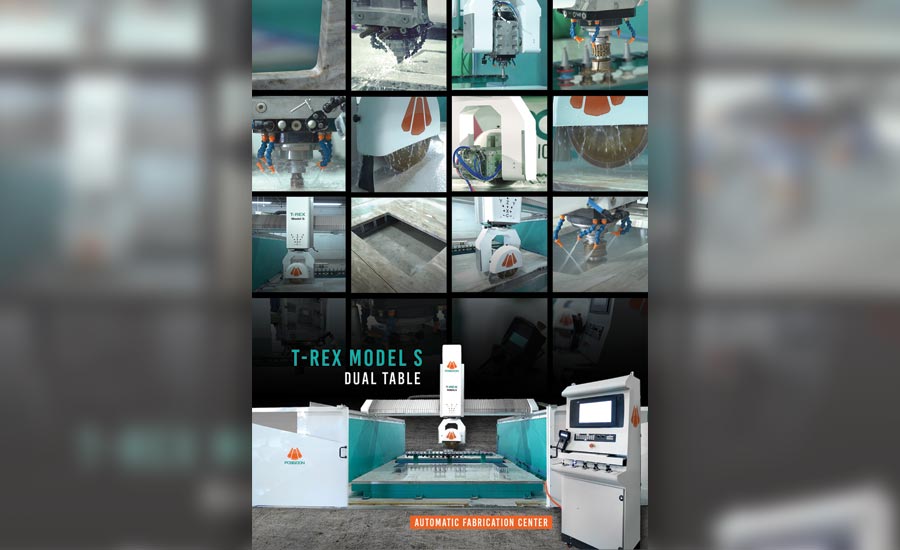

The T-Rex Dual Table Complete Fabrication Center: Poseidon

The Poseidon T-Rex Dual Table Complete Fabrication Center is the only machine to do all three phases (cutting, prepping, edge finishing) of the fabrication process and the only machine on the market that uses the “hybrid” cycle, allowing for cutting and routing in the same cycle. Also, the T-REX is the only machine that does upside-down cutting (the “Poseidon Plunge”) and is the only machine to do phase two (prepping [radius and shape prep]) and phase three (edge finishing) fabrication without stopping. The Model S Dual Table is the best seller. The Model X is geared for dimensional stone and countertops.

www.poseidonmachinery.com

WATER FILTRATION system: WATER TREATMENT SOLUTIONS

Water Treatment Solutions (WTS) pioneered the 100% closed loop, chemical-free, water recycling system for the stone industry. The company is an innovator in producing both crystal clear recycled water at less than 2 micron and gray/white water at less than 25 micron. With over 800 systems installed across the U.S., Canada, Mexico, South America and the Islands, WTS knows that water is the backbone of your shop – that’s why it prides itself on providing the best customer service. In 2017, its customers will collectively recycle over six billion gallons of water! WTS is also dedicated to the well-being of your team. That is why we use no chemicals in its process and its system has the ability to capture the stone dust residue to such an extent that the air born silica dust is meeting and exceeding OSHA standards in WTS shops tested across the U.S.

www.watertreatmentonline.com

SAW/CUTTING MACHINERY: WILSON

The new Wilson Heavy Duty Plunge Cut Saw is becoming a favorite among the company’s limestone customers. It has double the HP of Wilson’s regular heavy-duty saw and a new drive system that is proving to be a beast at cutting stone. The Plunge Cut saw has a wider and longer main beam, allowing it to cut up to 10-foot-long blocks. The Plunge Cut saw can be purchased in three different sizes and is fully programmable with the company’s UL Certified Mitsubishi Control Systems. It can also be installed inside or outside, with an additional weatherproof package.

www.wilsonsaws.com