Stone and tile industry professionals from around the world converged on the Georgia World Congress Center in Atlanta, GA, for Coverings 2018. The international stone and tile show filled the expansive exhibition hall with more than 1,100 exhibitors from May 8th to 12th – offering numerous displays of new stone and tile collections, innovations in product lines for stone and tile care, maintenance and installation, as well as fabrication machinery and new introductions of tooling and accessories for stone fabrication.

Debuting this year at Coverings 2018 was the Orientation Theatre. Stationed just outside the exhibition hall doors, this new feature provided a space for attendees to regroup and receive all the pertinent information they needed to make the most of their show experience, including answers to the most frequently asked questions and tips and tricks for tackling the massive show floor.

Further enhancing the show experience was the 2018 upgraded version of the Coverings mobile app, which assisted attendees and exhibitors in navigating the exhibition hall. Among the features of the app included an Online New Product Showcase that allowed discovery of the new product displays, as well as providing the opportunity for show attendees to mark favorites and visit those booths on the show floor. Additionally, the Meet @ Coverings feature allowed show-goers to meet face-to-face at Coverings 2018. They could add their profile in the app so attendees and exhibitors were able to connect with them directly and request a meeting through their profile. There was a dedicated lounge space onsite for meeting and networking in-person. Audio Tours were also available through the mobile app. Attendees had an opportunity for a self-guided exploration of the show floor to experience an enhanced educational component at Coverings, as well as an overview for those that are new to the show.

The stone arena

Throughout the four-day event, there seemed to be an energetic vibe in the stone fabrication machinery area. “The health of the industry is really good as far as fabricators goes from our perspective,” said Stephanie Kadlec of Park Industries. “While they may be in a pinch when it comes to labor, we see fabricators doing more business than in recent times. They are doing things a lot faster and more efficiently. The show was busy, and we saw a lot of traffic at our booth. We are really pleased with it.”

Paula Perry of Water Treatment Solutions in Hampton, NH, shared similar thoughts about the show. “We have had prospective new customers stop by our booth, as well as existing ones,” she said. “It’s giving us a good chance to reconnect.”

Many manufacturers were debuting new products – both large and small. Once again, the Stone Fabricators Alliance (SFA), an organization dedicated to the education of fabricators, created a buzz with its ongoing demonstrations and educational “how-to” topics in “The Cage.” The topics covered were specifically designed for fabricators and installers, and also products were featured that were “born on the SFA” — products designed by fabricators for fabricators. Additionally, the Natural Stone Institute (NSI) had a strong presence on the show floor – offering a wealth of information on everything from the benefits of using natural stone to best safety practices in the fabrication shop.

Moreover, machine demonstrations drew crowds and maintained a steady hum throughout the exhibition hall. Park Industries showcased its new SaberJet that can miter with both the blade and waterjet, while Salem Stone awed visitors with its T&D Robotics Lapisystem — featuring six operating axes and capacity to perform complex 3D machining, as well as saw cut, waterjet cut, route, drill, miter, edge polish, surface polish and manipulate slabs and work pieces throughout the production environment. This piece of innovative technology is designed to minimize labor – addressing the staffing issues many fabricators are currently faced with. Well-known for developing one of the first robotic SawJets, Baca Systems introduced its latest machine, the Baca Edge – designed for edge polishing. Gmm also made a grand introduction of its new Intec 713 waterjet – specifically designed for cutting porcelain and ultra compact/sintered stone surfaces. The Italian machine manufacturer was excited to announce its partnership with Australia-based Techni Waterjet. The companies mentioned are only several of the numerous machines, equipment, tooling and accessories that were presented during Coverings 2018.

Complementing the exhibition was an educational component featuring more than 45 sessions that were free to attend. Held annually, this year’s Fabricator Forum was set-up a little differently to allow for more audience participation. After a brief introduction of the panel of seasoned veterans, attendees were separated into four breakout groups, focusing on Business Management, Sales and Marketing, Fabrication and Installation. Participants were instructed to choose the group that most had their interest and a lively discussion took part in each – led by one of the panelists. The group then came together later in the session to share what they talked about in their small groups.

The dates for the 2019 edition of Coverings have been already set. The show moves back to the Orange County Convention Center in Orlando, FL, from April 9th to 12th.

Sidebar:

NSI holds tour at Coverings 2018 for new and innovative products from the marketplace

The Natural Stone Institute (NSI) held an interactive tour for fabricators at Coverings in Atlanta, GA, to visit vendors on the show floor and learn about new products that are available to the industry. The tour was led by Tony Malisani, of Malisani Inc. and GK Naquin of Stone Interiors.

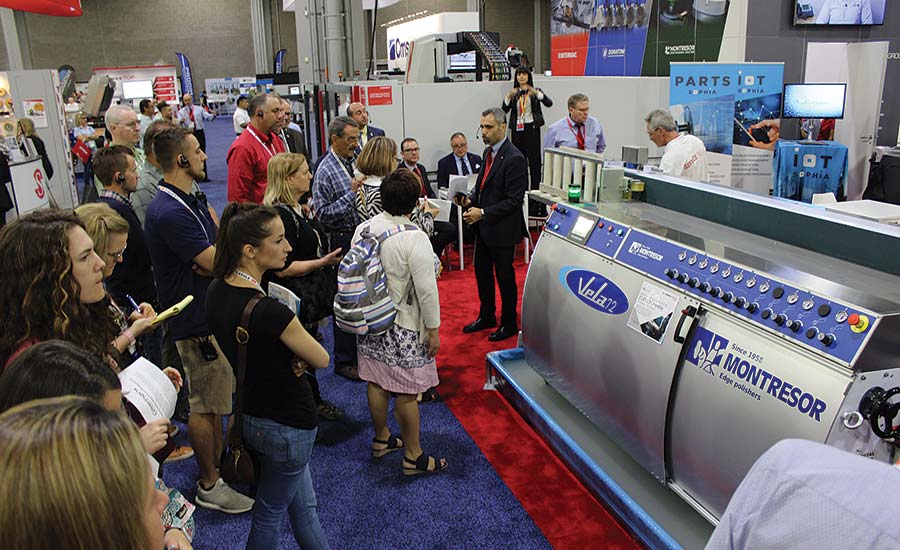

The first stop on the tour was at Intermac, where they demonstrated the Montressor Vela edge polisher. Because of the conveyor belt system it employs, the polisher can polish a piece of stone as small as 2 inches. It also features easy access to the polishing heads in the back, making tool change easier.

Next was Baca Systems where participants were shown the Robot SawJet. The completely sealed 2.0 version lets them remove about 80% of the wiring in the machine, reducing downtime.

The group then went to Park industries to view the companies SawJet lines, the Fusion, SaberJet and Optimus. The goal was to have a line, or version, of SawJet that could fit anyone’s needs, a Park representative told the group.

Following Park Industries, Integra Adhsives discussed its acrylic-based adhesives and also its MitreForma clamps. The company’s adhesives allow for exact color matching, while the MitreForma Clamps can help glue up any miter.

The tour also included a stop at Miles Supply where there was a demonstration of the company’s Ultraviolet Repair Kit, which repaired a stone in two minutes. Next up, Water Treatment Solutions showed its water recycling system. The company discussed its filter press system and how different sizes are needed for different size shops, and the importance of having clean water running through the fabricator machines.

At Prussiani Engineering, the group watched a demonstration of the Cut & Move CNC saw and learned of its capabilities of being able to process 40 slabs in an eight-hour day.

Lackmond Products demonstrated its Omega Tool Measuring Machine, showing the small footprint it has, allowing fabricators with a small shop to easily find space for the machine. GranQuartz showed their Zoeller Smile machine, allowing fabricators to save machine time on the initial set up of new profile tooling by getting precise measurements within minutes. Finally, the last stop was to Laser Products, who hosted a live demonstration of its LT2D3D Laser Templator — showing fabricators how easily and quickly digital templating can be completed.

|

NSI holds tour at Coverings 2018 for new and innovative products from the marketplace

The Natural Stone Institute (NSI) held an interactive tour for fabricators at Coverings in Atlanta, GA, to visit vendors on the show floor and learn about new products that are available to the industry. The tour was led by Tony Malisani, of Malisani Inc. and GK Naquin of Stone Interiors. The first stop on the tour was at Intermac, where they demonstrated the Montressor Vela edge polisher. Because of the conveyor belt system it employs, the polisher can polish a piece of stone as small as 2 inches. It also features easy access to the polishing heads in the back, making tool change easier. Next was Baca Systems where participants were shown the Robot SawJet. The completely sealed 2.0 version lets them remove about 80% of the wiring in the machine, reducing downtime. The group then went to Park industries to view the companies SawJet lines, the Fusion, SaberJet and Optimus. The goal was to have a line, or version, of SawJet that could fit anyone’s needs, a Park representative told the group. Following Park Industries, Integra Adhsives discussed its acrylic-based adhesives and also its MitreForma clamps. The company’s adhesives allow for exact color matching, while the MitreForma Clamps can help glue up any miter. The tour also included a stop at Miles Supply where there was a demonstration of the company’s Ultraviolet Repair Kit, which repaired a stone in two minutes. Next up, Water Treatment Solutions showed its water recycling system. The company discussed its filter press system and how different sizes are needed for different size shops, and the importance of having clean water running through the fabricator machines. At Prussiani Engineering, the group watched a demonstration of the Cut & Move CNC saw and learned of its capabilities of being able to process 40 slabs in an eight-hour day. Lackmond Products demonstrated its Omega Tool Measuring Machine, showing the small footprint it has, allowing fabricators with a small shop to easily find space for the machine. GranQuartz showed their Zoeller Smile machine, allowing fabricators to save machine time on the initial set up of new profile tooling by getting precise measurements within minutes. Finally, the last stop was to Laser Products, who hosted a live demonstration of its LT2D3D Laser Templator — showing fabricators how easily and quickly digital templating can be completed. |