Currently housing a

fabrication shop and showroom under a 6,000-square foot facility, Dauter Stone

Inc. of Calgary, Alberta, Canada,

plans to expand its production area and equipment line. Owning multiple CNC

machines from CMS North America of Caledonia, MI, the company will likely

purchase a third in the near future.

Beginning as a tile business, Dauter Stone Inc. of Calgary, Alberta, Canada, is now a successful stone fabrication facility - specializing in residential countertops as well as commercial cladding. The evolution into stone fabrication has called for investing in the latest in technology, including two CNC machines from CMS North America of Caledonia, MI, and it now garners room for more production space and a possible third CNC.

A CMS Brembana Falcon

CNC saw center was the company’s most recent investment.

The 6,000-square-foot facility is equipped with a CMS Brembana Falcon CNC saw, which was the company’s most recent investment. “That has vacuum manipulator arms that come down and move pieces out of the way,” said Leschyshyn. “That saves a lot of time.”

Purchasing the Falcon, which uses the Konig Plus blade from GranQuartz of Tucker, GA, has increased Dauter Stone Inc.’s production, according to Leschyshyn. “It’s increased the cutting capacity quite a bit,” he said.

Additionally, the shop is equipped with a CMS Brembana Maxima CNC stoneworking center that utilizes tooling from ADI, which is distributed by GranQuartz, a T108 manual workcenter from Thibaut of France, which features radial arms running along its track and a Fickert+Winterling saw that can accommodate blades as large as 2 meters in diameter.

Purchasing the Falcon, which uses a Konig Plus blade

from GranQuartz of Tucker, GA, has increased Dauter Stone Inc.’s production,

according to Shop Manager Brian Leschyshyn. “It’s increased the cutting

capacity quite a bit,” he said.

Expecting to expand its production, Dauter Stone Inc. is currently constructing a 6,000-square-foot addition to its facility, where it has plans to add another CNC stoneworking center. “Of course, we want to expand the business on both sides - kitchen and commercial,” said Leschyshyn. “Our current 6,000-square-foot building houses the showroom and production facility. We have under construction another 6,000-square-foot facility that will be the new showroom and slab warehouse. Once that has been completed, the old building will be converted to all production, and we will be adding another CNC workcenter.”

The shop also

operates a CMS Brembana Maxima CNC stoneworking center, which utilizes tooling

from ADI, which is distributed by GranQuartz.

Leschyshyn further explained that the staff is usually hired without experience, and then Dauter Stone Inc. puts them through its own in-house training program. “Up here in Canada, there’s not much in the way of training programs to send them to,” he said.

The shop’s most recent work involves some commercial and institutional projects. “We’re just finishing up the Centennial Towers in downtown [Calgary],” said Leschyshyn. “We did the cladding and granite flooring, stairs, etc.

“About 95% of our countertop business is done in and around Calgary, and 5% of the business is in places like Canmore, Banff and the interior of British Columbia, such as Invermere,” he continued. And although the company works with natural stone approximately 90% of the time, the other 10% features work that utilizes engineered stone such as CaesarStone quartz surfacing and Quantra quartz surfacing from Pokarna Ltd. of India.

A T108 manual

workcenter from Thibaut of France is used for surface finishing.

Sidebar: Dauter Stone Inc.

Calgary, Alberta, CanadaType of work: residential countertops and commercial cladding

Machinery/equipment: a Brembana Falcon CNC saw and a Brembana Maxima CNC stoneworking center - both from CMS North America of Caledonia, MI; a T108 manual workcenter from Thibaut of Vire, France; a Fickert+Winterling saw from Germany; tooling from ADI, which is distributed by GranQuartz of Atlanta, GA; blades from GranQuartz; an LT-55 Laser Templator from Laser Products of Romeoville, IL; Global StonePro software for job tracking

Number of employees: 15 in the kitchen department, around 25 in the commercial department

Production capacity: four kitchens a day, plus commercial and institutional work

The shop currently

produces an average of four kitchens a day under one shift plus commercial

work, and employees are divided into departments - with 15 in the kitchen

department and around 25 in the commercial department. “Quite a few workers can

do every aspect,” said Leschyshyn. “And then quite a few can only do polishing,

installing, etc.”

Additional Photos

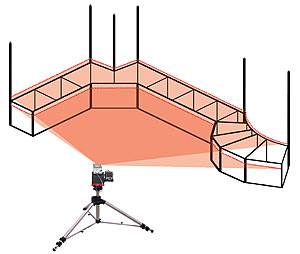

Templating is done

using an LT-55 Laser Templator from Laser Products of Romeoville, IL, (an

example of which is pictured). Digital templating along with CNC technology are

all factors in what has helped Dauter Stone Inc. advance in the last five

years, according to Leschyshyn.