Located in Massa, Carrara, Italy, International Italmarmi finds itself in the very heart of the natural stone industry, with other stone producers at every corner. So to make itself stand out from its competition, the company has brought in a diverse line of unique stone products, headlined by its signature material -- Blue Sodalite from South America.

The company, which is run by Roberto Nicastro, was founded in 1976, and it initially included the U.S. market among its export targets. After the mid-'80s, however, when high-end construction in the U.S. slowed, the company turned to markets in Europe and the Far East, where it supplied stone for many prominent structures. Completed works include the Nikko Hotel in Malaysia, the Portman Ritz-Carlton in Shanghai, China, and several hotels in Hong Kong as well as the World Trade Center in Stockholm, Sweden, and the Langham Hilton Hotel in London, England. The company's Sodalite has also been used for renowned structures such as Buckingham Palace in London and the palaces of sultans in the Middle East.

As the market changed in the late '90s, International Italmarmi's focus turned back to the American market. Today, the U.S. comprises 40% of the company's exports, with another 35 to 40% going to the U.K. The remaining exports go primarily to Northern Europe. To keep in touch with its American client base, an International Italmarmi representative goes to the U.S. every month to visit customers.

Working with the U.S. market can be a challenge, as the company must always be ready to introduce new materials. "There is no point in selling them materials they already have," Nicastro explained, adding that they have to closely monitor design trends and try to successfully introduce new materials to the marketplace.

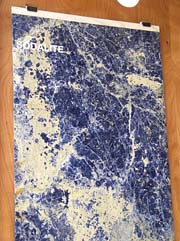

With this philosophy in mind, the company is continually bringing in exotic stones such as Blue Sodalite, which is quarried in the Andes Mountains of Bolivia at 12,000 feet. Sodalite is in the same family as Lapis Lazuli, and it has been used for jewelry as well as architectural applications. The company reports that the stone features strong technical characteristics as well as superior hardness.

Sodalite, which is used for high-end applications such as bathroom vanities and other three-dimensional arch-itectural pieces, is imported into Italy in block form, although the are smaller than standard marble or granite gangsaw blocks. International Italmarmi then processes the stone into various finished products as needed. The company has owned the production rights to the quarry in Bolivia.

Additionally, International Italmarmi has begun processing a new English Grey Fossil stone, quarried in Derbyshire, England, as well as White Onyx from Turkey. To ensure quality, the company has a geologist that visits the quarries on a regular basis to monitor the veining and color of the material being extracted at all times.

The company's latest development is a new facility in Massa. This 100,000-square-foot site allows for ample indoor and outdoor slab storage.

Currently, the facility includes a 13,000-square-foot building to house finished slabs.

To ensure quality service, a tracking system has been established so that everyone is aware of every step of every order. They take pictures of the slabs, and everything is cataloged so all parties have the same idea of the quality, color and veining of the slab. All of the slabs are registered on computer, so anyone in the office can check the status of the slabs electronically as well as in person. Blocks are also recorded with this system.

Additionally, a special form is completed with every order, so that everyone knows the exact status of the job throughout the entire process. They send pictures, or a customer comes and grants final approval to the company before packaging.

As a service to its clients, the company will send a mixed container to its customers, with a combination of granite, marble and other stones in both slabs and tiles. This practice bolsters sales of all materials, Nicastro said, as customers can -- for example -- buy two bundles of onyx and mix granite into the container as well.

In addition to tiles and slabs, cut-to-size work represents 20% of International Italmarmi's business, and the company has developed strong experience in this area over the past 23 years. The U.S. marketplace is important for cut-to-size sales, and the company has supplied many high-end projects. At the time of Stone World's visit to the company, it was in the process of supplying Bianco Carrara marble for the Liberty Bell surround in Philadelphia, PA. For this project, the company is supplying custom-carved pieces that will frame the bell itself. These pieces require the ultimate degree of precision, as they are all being cut on a very finely curved radius.

The company has ISO 9001 certification, which assures customers that the service is efficient and guarantees the quality of the material. To maintain this certification, the company undergoes two or three inspections per year, where each phase of the process is examined.

Resin processing

Following a trend that has been making inroads in the U.S. market, International Italmarmi offers marble, granite and other stones that have been reinforced with resin products. The marble slabs are reinforced with resin products and then polished. For certain materials, a fiberglass net is also adhered to the back of the slab for extra strength.In the first step of the process, the slabs are automatically delivered to a large oven, which removes any trace of water from the slab. This allows for maximum efficiency in applying the resin. After this stage, the resin is applied to the surface, and the slabs are moved to a second oven, where the resin is dried at a rate much faster than it would naturally dry. If needed, the slab is then flipped, and the resin is applied to the other side of the slab as well.

Depending on the amount of variation within the marble slab, the resin is either applied automatically or by hand, as workers may have to rely on their personal experience to determine which areas of a slab will need the most resin. When additional reinforcement is necessary, the slab is treated with a polyester resin and fiberglass netting is also used when needed.

After the resin is applied and the slab is fully dry, the material continues on to a 6-head Breton calibrating line, which is equipped with diamond abrasives. After calibration, the slabs continue to a 14-head Breton polishing line.

After polishing, a water-based liquid wax product, is applied to the slabs. This product makes the surface of the slab oil and water repellent in indoor or outdoor environments.

International Italmarmi also supplies resin-treated granite slabs. Its granite is processed at one of two facilities, including one facility for resining material and one for slabs that do not need resining. This second plant also processes edge work for vanities and countertops.

At the plant for granite resining, a very specific process is used to apply the resin to the slabs. The stone begins in a honed format, and then the slabs are placed in a large-scale oven from Breton to remove the water from the stone. Similar to the marble process, this allows the stone to more readily accept the resin. Again, the resin products are either applied by hand or automatically, depending on the material being processed. Afterwards, a vacuum chamber drives the resin deeper into the stone, and the slabs go into a second oven for quick hardening. These ovens can dry/harden up to 40 slabs at one time.

Once the resin has dried, the slabs are processed on a Levibreton KG 2000 from Breton, which has a total of 19 polishing heads. This unit was computer-engineered for optimum speed, precision and efficiency in processing granite slabs.

International Italmarmi's slab processing totals 70,000 square feet of material per month. Of this amount, 70% is granite and 30% is marble.

When processing customized stonework, the company first relies on a series of bridge saws and drilling machines. Additionally, stone is processed with a Comandulli edging machine, a waterjet and a pantograph for three-dimensional work.

In the near future, International Italmarmi plans to take full advantage of its new facilities by expanding its production and continuing to introduce and promote new materials to the international marketplace. In addition to having an international sales force and advertising in international trade magazines, the company exhibits at trade fairs around the world.