The company was established on January 1, 1989 by Joanne Martino, a native of Pueblo, CO. "I saw a need in the [Denver] market," she said. "Stone was really coming on board." Stone Craft began in a 600-square-foot shop with one saw and three employees. "We did high-end kitchens, and we did a lot of city work and airport work."

As time went on, the company steadily became busier, and it moved to a new 4.5-acre location in 1992. "The office and fabrication shop was 11,200 square feet, and we brought in an old Ty-sa-man saw," Martino said. "We were doing all materials, including granite and ceramic tile." In 1994, Stone Craft merged with Krizner Tile & Marble Co. and Versatile, Inc., both highly successful companies.

The company's latest expansion came last year, when it established a new facility on its existing property. "We finally outgrew the fabrication shop here," she said. "We figured that there was 5,000 feet of shop [previously], and I had a vision to build an 18,000-square-foot facility."

The expansion was not limited to a new facility, however, as Stone Craft purchased a full range of state-of-the-art stoneworking equipment. New machinery at the plant includes two Zonato bridge saws, a MondialMAC edge polisher and Dal Forno vacuum lifting equipment, all of which was purchased from International Machine Corp. of Holbrook, NY. The company also invested in a Breton NC 160 computerized stoneworking center.

Two different models of Zonato bridge saws - the 500 and 700 - were purchased by Stone Craft. "I was looking in the trade magazines, and I had known the [the owners of International Machine Corp.]," Martino said, adding she started negotiating price, and once that happened, they shipped the machinery to the Coverings show in New Orleans, LA, in May 2001. From there, the equipment was shipped to its final destination, Stone Craft. The Zonato Model 700 bridge saw, which has a cutting depth of 15 cm, is used for mass production. "We knew we were going to go into manufacturing for other people, so if there was a job that could be cookie cut, we could stack the slabs and cut them all at once with the 700."

The Zonato Model 500 bridge saw is used for more typical applications. "We also knew we needed a saw for custom work - kitchens and such," Martino said, adding that the MondialMAC Luca 88 edging machine was chosen for its automation capabilities. The machine automatically processes edgework - from the rough forming of the edge to the final polishing of stones with a thickness ranging from 3/4 to 5 1/2 inches. A programmable computer allows the company to store and recall various profiles from memory.

The Breton NC 160 is capable of a broad range of functions - including shaping, profiling, milling, chamfering and drilling - which are carried out automatically via the computer. The machine is equipped with two worktables, which allows the machine to process a piece of stone on one table while slabs are loaded and unloaded from the other table. "We sat down with the owners [of Breton] and asked them to show us the difference between the single table and what we ended up purchasing," Martino said. "And we figured it would be better to make the investment and let the machine take us to where we want to go."

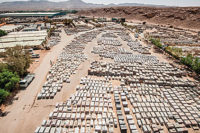

With the equipment in place, Stone Craft is currently fabricating stone for six complete kitchens per day in a single shift. "We're hoping that with two or three shifts that we can triple that capacity," Martino said, adding that about 60% of the company's fabrication work is residential projects, with the remainder being commercial spaces such as hotels and loft space. Stone Craft poured a 60,000-square-foot pad of concrete to house over 4,000 slabs. Over 200 types of natural stone are in stock.

In addition to doing the fabrication and installation for their own client base, Stone Craft has started for fabricate for other firms. "We have even become the selected fabricator for DuPont's Zodiaq product in the region," said Martino "Since we are [already] fabricating for Corian, and installers are starting to get into natural stone, it opened another market for us."

The company presently has a staff of 51 employees. "Right now, we are very fortunate to have the employees that we have," Martino said, adding that they have a training program in place for new workers. In addition to fabricating, the company installs stone for selected customers, but its preferred market is manufacturing. "It keeps us away from liability issues."

With the equipment up and running, Stone Craft has become a model of growth among stone fabricators. In May of 2001, Stone Craft hosted over 100 people as part of the Building Stone Institute Study Tour, held in Colorado in conjunction with the Tucker Awards. "Many positive comments came," Martino said. "People said we really stepped up to the plate." And even with the extensive growth over the past year, Martino said that more expansion may be coming in the future. "If business keeps going the way we anticipate it, we will probably be buying another Breton NC 160 and adding the Breton CTX to the family," she said.