As a proponent of natural stone and sustainability, Tab India still found it necessary to recognize the growing trend of quartz surfacing. Brothers Amit and Sumit Gupta established the stone operation in 1997, and experienced quick success. Today, the company has grown to own more than 12 stone quarries – in numerous varieties – and branded its name in the stone industry worldwide. But as the industry and market trends continue to evolve over time, Tab India made the decision to grow with it by opening a new factory for TabQuartz in the beginning of 2018.

“TabQuartz started commercial production in January 2018 after running a series of trials and tests on various colors, patterns, polish techniques and finishes,” explained the Gupta brothers. “Tab has consistently and continuously adapted to the market dynamics. Getting into quartz production was an organic step forward, expanding our existing footprint in the natural stone and surfaces industry.”

According to the Gupta brothers, the ultimate decision to open the quartz plant came from the pressure and demands of Tab’s distributors worldwide to supply quartz slabs and cut-to-size in quartz, of the same quality levels as its natural stone offering. “We re-engineered the whole process of quartz production to ensure that the final product could stand the test of Tab’s polish/finish quality precision which we are known for in the stone industry,” they said. “The addition of quartz to the product range also makes Tab a unique one-stop shop for natural stone and quartz. We give the option to our customers to be able to mix their granite and quartz orders, if need be, as the granite and quartz plants are located on the same campus in South India. It also helps that India houses some of the best quality reserves of natural quartz material in very high deposits, which is in line with our policy of sourcing only the best raw materials.”

DEVELOPING A “NEW AGE” QUARTZ

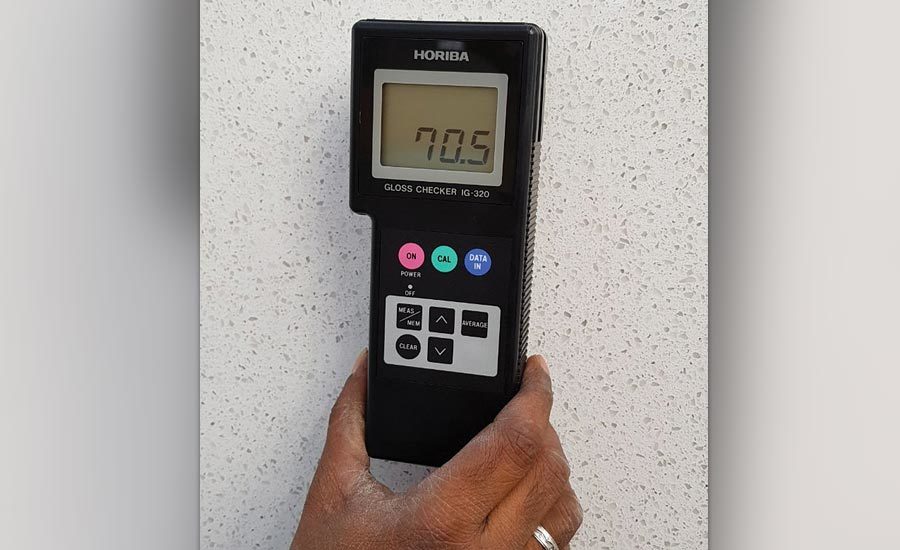

Tab has designed and developed a technology which has resulted in the evolution of normal quartz slabs to a “New Age” quartz, the Gupta brothers explained. “Tab re-engineered the production process using very high-quality quartz and specialty resins suitable only for production of low VOC quartz — ensuring very low-resin inside the slabs, pressed on a highly efficient and strong vibro-vacuum press,” they said. “The unique combination of inputs gives the surface a new construction definition. All the colors remain in the development, testing and prototype stage until they are proven fit for commercial production. The surface finish and the density thus achieved makes TabQuartz a New Age quartz.”

The company built a state-of-the-art laboratory two years before the commencement of the commercial production. “This was done with the plan to ensure that there would be a vast range of colors ready to go into production as soon as the machines were installed,” said the Gupta brothers. “Tab developed more than 300 colors and patterns successfully because of this early investment into the lab and is now releasing new designs and patterns regularly. The first offering that we came out with in the market was for 24 colors to keep the introduction simple for our customers, which was increased to 36 in three months, after adding 12 more colors; the same will keep getting added with the new trends as the market demands and allows. We do not want to come in and disrupt the market immediately, but the lab and the lab technicians are primed and ready to keep coming up with newer and better looks. Backed by the fully automatic molding and polishing process machines, making new colors has been made easier.”

TabQuartz is part of the 35-acre campus, which also houses the natural stone slab, tile and cut-to-size facilities in a green campus, built with solar-power generation, rainwater harvesting, 100% water recycling and many other carbon footprint reducing efforts. The quartz production facility has a covered constructed area of 150,000 square feet and another 50,000 square feet of supporting and ancillary functions. “The line is capable of producing up to 250 slabs per day in thicknesses of 15/20/30 mm,” said the Gupta brothers. “We are currently producing 200 slabs a day, equivalent to about 100 standard containers capacity per month. With the addition of the second production line soon, this capacity will double. The existing infrastructure/facility has been built keeping this in mind for expansion.”

Tab India’s primary markets remain the same as its natural stone markets, which are North America, South America, Europe, Australia and Asia Pacific. “The guiding philosophy for Tab has always been to produce goods and provide services of the highest standard, and we have done the same for all of the products and services that we offer, including TabQuartz,” said the Gupta brothers. “We have established a brand and value for our company and its products in the market, a legacy that we have to carry forward with offering quartz of the highest possible quality and value than has been done so far.”