Just as there has been major advancement in equipment for cutting, shaping, polishing and edging stone products (as reported in the January 2009 issue of Stone World), there have also been significant developments in the tooling, accessories and other products for stone processing and countertop production.

These new introductions in this sector include tooling and accessories such as blades and polishing wheels, as well as products for handling and storage, software, digital/electronic templating, air and water treatment systems and other shop products. The following is a look at some of the latest advancements in this area.

Tooling and Accessories

Abrasive Technologyoffers specialized P.B.S. stone tools for custom edge shaping. The brazed tools are developed for high-end users needing a custom tool for a special project, and Abrasive Technology reports a quick turnaround time. The P.B.S. tools are designed to rapidly remove a significant amount of material, leaving a smooth surface finish ready for polishing. The tools can be designed to fit any and all machinery.

Ghines carefully controls each step of the production process, from the manufacturing of the metallic supports to the diamond application. The geometry of each tool is achieved with the necessary increments so that all the steps can be accomplished without modifying the spindle trim. Thanks to accurate manufacturing and the capability of tools to retain their shapes, replacing a single wheel is now possible without resetting all the other tools, offering savings in time and money, the company reports.

Ghines wheels are suitable for any stone material, and they fit any manual or CNC machines. Ghines rubber and sintex polishing wheels are interchangeable without modifying the settings.

The bit can cut curved lines as well as straight lines.

The CL-830B features a patented “Linear Lens” and the company’s state-of-the art “Powershift” technology. It also comes complete with a bracket that is simple to mount and easy to adjust as well as a power supply that wires directly into the panel and works with both 110- and 220-watt power.

The polishing wheels are designed to achieve a high polish with a special continuous multi-layered resin formula. Additionally, they cut down on manual polishing and material handling costs because users will not have to finish edges by hand, Diamax reports.

Minimal deformation of metal positions leads to efficient polishing output, and there is no need to reshape metal positions.

Specifications

- Blade length (continuous band): 61.5 inches (1.562 m)

- Blade thickness or kerf: 0.01969 inches (0.050 mm)

- Blade depth: 0.1772 inch (4.5 mm)

- Blade life estimate: Approximately 80 to 100 hours (cutting time will vary based on material cut and operator experience)

UHS technology allows a fabricator the option to more than triple a profile tool’s speed or double its tool life. According to the company, the new UHS profile tool can perform at a rate of up to 150 inches per minute. UHS technology also makes it possible to now mill bowl holes at a feed rate of up to 24 inches per minute, according to GranQuartz, while enjoying longer tool life.

“ADI’s existing Eraser System is being supercharged with UHS technology for the ultimate blend of speed and polish quality. In fact, the biggest constraint to a fabricator’s productivity now is whether the fabricator can keep up with the speed of the UHS tools,” said Paul Taylor, Diamond Consumables Product Manager for GranQuartz. “A fabricator can achieve much greater utilization of their biggest capital investment, their CNC, with ADI Ultra High Speed tools.”

The Backsplash Polishing Workstation includes an aluminum stand with Velcro for pads, two grinder holders, two 5-foot Sink Hole Savers (SHS) and two pairs of SHS mount brackets (enough to hold four Sink Hole Savers). All Omni Cubed products are engineered, manufactured, and assembled in the U.S. and are covered by a one-year manufacturer’s limited warranty.

Also available is the Multi-Seam Expansion Kit, which includes two additional VC2 seam setters with storage case and an accessory coil tube adapter. The expansion kit enables installers to simultaneously join and level two seams (up to 14 feet apart with use of the coil tube and only one vacuum pump), saving time during the installation process. Installers can also “chain link” up to four seam setters together for larger seams (i.e. longer island seams).

The grinder can be used for polishing as well as core drilling.

Material Handling and Storage

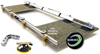

The Abaco KPT8340 Kitchen Processing Table is designed to allow users to work more efficiently. The tabletop tilts from being flat to stopping at various degrees so users can work more comfortably. It can easily handle slabs up to 1 ½ inches thick.The processing table is 79 inches in length, and it adjusts from 29 to 39 inches in height. It tilts at two angles, either 45 or 76 degrees. It comes with casters that make transportation easier, and the collapsible design saves on freight costs.

Size specifications:

- At flat position: 79 x 24 x 39 inches (2,000 x 600 x 1,000 mm)

- Tilt at 45 degrees: 79 x 24 x 46 inches (2,000 x 6000 x 1,180 mm)

- Tilt at 76 degrees: 79 x 24 x 49 inches (2,000 x 600 x 1,250mm)

The ALG50 has a grip range of 5/8 to 2 inches (15 to 50 mm); the ALG60 has a grip range of ¾ to 2 3/8 inches (20to 60 mm); and the ALG75 has a grip range of 1 1/8 to 3 inches (30 to 75 mm). All three have a weight limit of 2,202 pounds (1,000 kg).

Features:

- Handy lever action assures safe dumping

- Reinforced steel makes the Dumpster last longer

- Heavy-duty channel forklift pocket and safety pin add stability and safety when unloading

- Compact design with two heavy-duty swivel casters with brakes and two rigid casters allows the Dumpster to be moved around the shop floor, construction site or through narrow spaces easily.

A new, compact, high-capacity vacuum lifter for granite and other stone materials within a small footprint is being introduced by Anver Corp.

Equipped with a 78-CFM pump, motors, reservoir tanks and an audio-visual alarm system, the Anver E4000M16 vacuum lifter has a safety interlock switch that prevents the release of a load until the lifter has been lowered completely. Each suction pad can be individually controlled to correspond with the load configuration.

Breton A.R.M. Systems are customized material warehousing solutions designed to automate the order-fulfillment process - starting with the receipt of inbound material and continuing to where it exits the facility as a finished product.

Incoming slabs are robotically picked from stock A-frames, and then they are photographed, marked for defects, applied with protective film and bar-coded for storage before being transferred to the warehousing unit.

Depending on the type of material to be stored, the warehousing units are engineered to store slabs vertically in a magazine configuration, or horizontally stacked in multi-level units, or a combination of both. The control automatically records the location of the piece prior to storage, and the operator only recalls the pieces required. Or, the entire process can be automated and integrated with Breton’s Fabmaster system.

At each stage, the workpieces can be automatically placed onto A-frames or conveyors for movement into workstations or positioning onto the worktables of the machines. The cut-to-size and finished pieces are conveyed back into the warehousing unit for storage prior to installation, where they can be called and their status updated.

Gorbel workstation cranes and Manzelli vacuum lifters are a proven way to improve productivity, increase quality and provide a safer work environment. According to the company, customer case studies found that the use of a Gorbel workstation and a Manzelli Vacuum Lifter increased productivity by 25%. Through the automation of Gorbel and Manzelli, one person can move a slab efficiently and safely, GranQuartz reports, adding that Gorbel workstation cranes are easy to install and are available in steel or patented aluminum. Custom-built to the size of any shop, the freestanding overhead cranes have capacities ranging from 250 to 4,000 pounds.

Manzelli lifter models range in capacities of 1,100 to 4,400 pounds and include many standard features, including automatic safety alarms for sufficient vacuum power, adjustable vacuum plates to fit different pieces such as L-shaped tops, rubber gaskets to lift polished, honed or some rough-cut materials (may reduce load capacity), vertical/horizontal tilt from 0 to 90 degrees, an emergency backup reservoir if the primary air supply is interrupted, a vacuum line filter to trap dust and moisture, an overhead hooking eyebolt and an electro-welded and corrosion-resistant steel frame.

Groves also manufactures a complete line of fabrication tables, storage racks and transport carts.

The optional upgrade kit enables the cart to be folded for easy storage (reduces cart width to only 9 inches).

The Original Sink Hole Saver TM is suited for keeping tops in one piece during installation, but the innovative edge-clamping design allows it to be used for other applications such as for lifting stone off CNC and waterjet machines; for protecting stone during transport on A-frames; and during manual fabrication to strengthen the top while cutting.

The Sink Hole Saver TM VC1 features thumb-pumped cups, and the Automatic Sink Hole Saver TM VC2 features an automatic vacuum pump that operates on a 9-volt battery. Both secure to countertop surfaces with durable 6-inch vacuum cups. These vacuum cup rails are used during installation of curved or “bump-out” countertops, and they are often combined with the Original Sink Hole SaverTM (clamp version) for added versatility during tough installations.

The SHS Angle Bracket allows protection of “L,” “bat wing,” or any other angled countertop during transport and installation. The bracket connects two Sink Hole Savers of any length, allowing rotation of 0 through 270 degrees. The product works for inside and outside corners, making it especially helpful for the installation of fragile “L-shaped” countertops.

SHS Vacuum Cup Attachments are added to an existing Original Sink Hole Saver to enable installers to “flip” between two systems. The install crew can use the mechanical clamps for countertop transport on the A-frame, and then they can “flip” the same rail to the vacuum cups side for the final installation.

With movable vacuum pads and sliding adjustable pad arms, the FL6HV11AC flat lifter offers the ultimate versatility for handling irregularly shaped slabs or for avoiding sink cut-outs, defects or surface obstructions. This vacuum lifter comes standard with an AC vacuum pump and 1,000-pound (455-kg) capacity, and it is also available with a compressed air or DC power system, as well as other capacities.

The FL12HV11AC flat lifter features a 3,000-pound (1,360-kg) capacity, making it Wood’s Powr-Grip’s highest capacity flat lifter for stone handling. Movable vacuum pads and optional pad shutoffs enable this vacuum lifter to handle a wide variety of slab sizes and shapes. It comes standard with an AC vacuum pump, and it is also available with a compressed air or DC power system, as well as other capacities.

The MRTA8HV11DC lifter features DC power, 360-degree manual rotation and mechanically assisted 90-degree manual tilt. Movable vacuum pads and extension arms accommodate nearly any size or shape of stone. A high-flow vacuum system helps overcome leakage associated with semi-porous or contaminated stone surfaces. It has a standard capacity of 1,200 pounds (545 kg) and is also available with an AC power system.

Offering economy and versatility at the job site or in the shop, the PF Series Vacuum Lifters feature manual 180-degree rotation and 90-degree tilt. A wide variety of models lets a shop select the vacuum lifter that best meets its stone handling requirements. Different configurations of vacuum pads are available for long and tall slabs, as well as for two different groups of stone weights. PF Series vacuum lifters are available with either cord-free DC power systems or economical AC pumps.

Powr-Grip’s MT Series stone lifters feature 90-degree tilt with an above-the-center pivot point so that slabs automatically hang in the upright position when lifted. The resulting narrow profile allows them to fit between tight, vertical storage racks while also protecting the remote power source. Foam pad rings and individual pad shut-offs are standard. Available power systems include AC, DC or compressed air. An optional flat lift adapter makes these lifters ideal for loading cutting tables, CNC machines or other horizontal processing machinery. Load capacities from 600 pounds (270 kg) to 1,500 pounds (680 kg) are available.

Featuring manually operated, 90-degree tilt between upright and flat positions, the MT5HV11AC is designed specifically for lifting, tilting and transferring medium-sized slabs between cutting tables, processing equipment and storage racks. While AC power is standard, this vacuum lifter is also available with a DC or compressed-air power system. Load capacity is 800 pounds (365 kg).

The N4300 Hand Cup combines Powr-Grip’s ABS plunger, durable metal handle and a flat vacuum pad. The result is a vacuum cup that is especially well suited for handling flat stone products. The ABS plunger does not rust in wet conditions, and the metal handle resists grit and contaminates common in stoneworking facilities. This hand cup has a diameter of 8 inches (204 mm) and a load capacity of 125 pounds (57 kg). It is also available with 9-inch (229 mm) flat and 10-inch (254 mm) concave vacuum pads.

Designed primarily for lifting in the flat position, the G609 Grifter cup allows for quick and easy handling of small tiles. All-rubber construction prevents rust in wet working conditions. It features a diameter of 3 ¼ inches (83 mm) and a load capacity of 15 pounds (7 kg).

LJ45HG, TL6HG and LP6HG Handi-Grip cups are well suited for handling floor tiles, small slabs and manufactured stone products. Different vacuum pads are available for gripping curved or flat stone surfaces. They feature diameters of 4 ½ (115 mm) or 6 inches (153 mm) and load capacities of 40 pounds (18 kg) or 70 pounds (32 kg) per vacuum cup.

Air and Water Treatment

The Abaco Dehydrator is a dehydration system for the fast collection and trapping of the abrasive mud produced by machining and finishing marble, granite and other stones. The Abaco Dehydrator was designed to offer an economical, one-step method in separating and dewatering sludges and slurries. The Dehydrator is constructed of stainless steel and consists of four basic components: pump, mud-holding tank, clean water tray and filter bags. The Abaco Dehydrator has no moving parts, requires minimal labor and is very economical to use. Since it is constructed out of stainless steel, it requires extremely low maintenance.Two versions are available - stainless steel and zinc sealed marine coated.

Also available is the Novair 1000 Negative Air Machine with a powerful 1-horsepower motor.

Cycle Description

Wastewater coming from the stone processing plant is collected in a pit or tank, where a float-actuated submersed pump automatically pumps the slurry into the cylindrical decant tank. Before reaching the tank, a flocculent is automatically injected into the slurry. The chemical action of the flocculent accelerates the suspended solid particles “falling” out of suspension. The treated slurry is pumped into the decant tank in a way that minimizes turbulence to further facilitate the efficient separation process. The “clean” water flows to the top of the decant tank, overflowing into a surrounding chamber while the heavier solids collect in the bottom of the decant tank. The treated water is pumped from the “clean water chamber” back to the processing machine by a centrifugal pump. The mud collected in the bottom of the decant tank is discharged into a filter press, where the water is finally filtered.Specifications

- Overall Dimensions (model CS): 7 feet, 4 inches x 17 feet high

- Overall Dimensions (model CF): 7 feet, 4 inches x 13 feet high

- Decant Tank Size: 6 feet, 6 inches x 6 feet, 6 inches

- Clean Water Reservoir Size: 1,320 gallons

- Maximum Waste Capacity (per minute): 132 gallons

- Solids Disposal (per hour): 16 – 42.24 gallons

- Power (kW): 10÷5

- Full Load Weight: 66,150 pounds

A unique and patent-pending feature of the MiniClean is its unique Turbo SprayTM nozzle system that permits the main bag to “weep” at its maximum rate.

Other water treatment systems available from VIC include the MicroClean and SlurryClean TM. The MicroClean is designed for companies that generate up to 50 gallons of water per minute, while the SlurryClean is best utilized in shops creating up to 200 or more gallons of water per minute.

The VeriDRY Dust System meets OSHA standards for the removal of airborne particles when installed and used according to the manufacturer’s specifications. These dust collectors have a 99.97% efficiency rating on submicron dust particles resulting from the dry grinding of granite, limestone, quartzite, bluestone, marble and other materials.

From the economical ClearTech to the standard EnviroSystem and up to the completely integrated systems of the Concentrator in concert with the EnviroSystem, WTT has installed configurations for fabricators doing one kitchen a week up to those fabricating 35 kitchens per shift. All of WTT’s systems guarantee 100% crystal clear recycled water, which is safe for all equipment in a fabrication facility. The company reports that it is the only manufacturer of its kind that has been endorsed and approved by all the major manufacturers in the industry.

Products are backed by a superior warranty and a solid customer service team.

Software and Electronic/Digital Templating

ETemplate Photo digital templating automatically verifies accuracy and intends to eliminate drive-backs. Its exclusive fully automated DXF/CAD drawing capability adds radii, overhang and more. No tape measure or field verification is necessary. According to the company, the program collects 500 million measurements per click of the calibrated camera. Users “deliver” the entire jobsite and all of its measurements back to the shop in the camera, and the software does the rest.ETemplate has the exclusive ability to visually verify the final countertop design by graphically placing it on the jobsite photographs to scale for quality control and customer approval. Users can extract any additional measurements needed directly from the photos while sitting at a desk in the fabrication shop. The template is parametrically adjustable to suit a shop’s customers’ design changes.

ETemplate Photo simulates the GPS system, with the calibrated camera representing the satellites. Shooting photos from various angles creates triangulation to specific fixed points in three-dimensional space. A pictorial history and integrated quality control features provides the fabricator a thorough set of information. Everything is automatically measured a minimum of twice to ensure optimal accuracy of measurements. The visual benefits further ensure accuracy by providing a photographic memory that goes beyond the measurements.

The system does not require a tripod or any leveling, and there are no limitations of range, reach or line-of-sight limitations. The CAD/DXF can be used to cut a vinyl template, print a detailed shop drawing or go directly to any CNC machine.

The ETemplate Render Tool also intends to help homeowners with the challenge of selecting a color/material for remodel projects. During the templating process, the homeowner can select colors in their computer-generated kitchen from the same photographs taken by the templater for measurement. The templater leaves the appointment with accurate measurements and the color selections.

Fabricators utilizing the ETemplate Photo software can load the kitchen photo into the rendering tool, providing an in-home countertop selection service for the homeowner, which aids in the entire production process - from measure to install. Retailers can allow homeowners to instantly see their selections rendered on their photos during the design appointment prior to purchase.

This new Kitchen Render Tool by ETemplate Systems is available in both CD and online format.

The powerful software included with the ETemplate 3D Laser draws points, lines, arcs and freeform curves in two and three dimensions. According to the company, this allows users to pre-measure vertical walls, outlet locations and more easily and accurately with a laser.

Unique functions include the ability to average lines using multiple points, which minimizes wall scribe and gaps between walls and splashes. The ETemplate 3D Laser may be used together with ETemplate Photo for measuring a single job when applicable, as well as being used independently. When both systems are used together, the data from both systems can be automatically linked together to create a single digital template. This complete integration of data allows both systems to be used to their greatest potential.

Both residential and commercial templating projects can benefit from using the ETemplate 3D Laser as a standalone as well as in combination with the ETemplate Photo 3D digital measuring system.

The machine’s weight is only 18.7 pounds (8.5 kg), and the measuring head can be folded into the machine for optimal protection during travel. A socket connection, as well as the possibility to use rechargeable batteries, provides optimal flexibility. The machine has a USB port, so results can be downloaded onto a laptop or USB stick, and the digitizing processing can be started immediately.

The software platform of the Proliner 8-Series is very extensive and offers a variety of possibilities. It has extensive integrated CAD software, so users can complete the drawings on the jobsite and prepare for production.

The Proliner 8 Series can measure up to 45.9 feet (14 m). With the integrated Leapfrog software, larger surfaces can be measured. Although the model is small and compact, it has ample extra storage space. It is possible to carry two spare batteries, a digital camera and other add-ons, with space for additional other items.

The design of the Proliner 8 Series is advanced in functionality and aesthetics. It has been made to provide maximum comfort, stability and durability. The 8.4-inch touch-screen makes the Proliner 8 Series very user friendly.

The integrated speakers enable the user to adjust the beep-volume, which makes it suitable for noisy working environments. A LED light indicates the status of the battery.

With all Proliners, there is no need for leveling the unit. The Proliner 3D offers both two-dimensional and three-dimensional files, while the Proliner 2D only offers two-dimensional results.

In the Western U.S., the Prodim Proliner is available from Blick Industries.

The Proliner 6 series has basic integrated CAD software that allows users to complete drawing on the jobsite and prepare for production. A 6-inch touch-screen facilitates ease of use, while the integrated speakers enable the user to adjust the beep-volume - making the unit suitable for noisy working environments. A LED light indicates the status of the battery.

With all Proliners there is no need for leveling the unit. The 3D model offers both two-dimensional and three-dimensional files, while the Proliner 2D only offers two-dimensional results.

In the Western U.S., the Prodim Proliner is available from Blick Industries.

Users can plan, measure, design and calculate countertops, and they can also visualize countertops, backsplashes, edges and cut-outs in the correct material directly on-site.

There are only six steps to measure a countertop:

- Define a reference plane for the projection by simply measuring three points

- Measure the external contour of the countertop

- If any, measure the internal contour (the one against the wall)

- If needed, digitize other shapes (holes, marks, etc)

- Users can then finish the drawing and transfer it to the USB-stick

- Open the results with the user CAD or CAM software

The Procutter Plotter cuts out a vinyl template in minutes. A shop can then place the vinyl on the slab for vein matching as well as showing the customer what a kitchen will look like on a specific material.

Management/Production Software

Breton FabCAM is a turnkey software suite designed for Breton’s multifunction machine, the FabCenter, a CNC router/saw combination allowing the user to perform four-axis saw cutting, routing and polishing operations starting from the slab. The process eliminates the need for the user to remove the cut pieces from the work environment, therefore saving time and effort.First, the slab is photographed, marked for defects and referenced. The FabCAM software is employed for auto tool-pathing and artistic nesting, and then the saw-cutting operations begin. The sawing operations are performed using a combination of the saw blade, core bit and fingerbit to achieve cut-to-size pieces with rod slots, including radius work. The cut pieces are then shifted for final routing and polishing, and complete slab layouts are machined with very minimal user intervention, increased accuracy and maximized efficiency.

The key features of Breton FabCAM are its one click tool-pathing process, a live interactive three-dimensional view of countertop project design - complete with backsplash and a three-dimensional live rendering and collision detection system. The software can be fully integrated with the “Imagemaster” inventory control system to optimize layouts across the entire inventory of slabs, thus potentially incorporating remnant pieces and the most suitable material for the project, which saves material, eliminates wrong cut piece errors and saves time.

The entire photographic system, the machine and the software are supplied and supported by Breton. The FabCAM software may be seen by contacting a local Breton representative or by searching “Breton FabCAM” atwww.YouTube.comto view the product in action.

With a wide range of pricing methods, QuickQuote can virtually price any material, and it allows different materials to utilize different pricing methods. Splashes, edging and premium items are automatically tabulated and separated out to provide maximum pricing flexibility. QuickQuote can also calculate slab counts for job costing and material layout.

Designed to seamlessly integrate with a shop’s existing systems, QuickQuote exports to QuickBooks, .DXF/.DWG and a host of other file formats. QuickQuote’s professional printouts put the quote and drawing together on a single page, and quotes in multiple colors and price levels side by side. Printouts can be further customized to include company logo, work orders, legal disclaimers and more.

Purchase of QuickQuote includes installation of a company’s entire product catalog, complete with pricing - including colors, edge options and sinks, along with all updates for one year.

JobTracker Enterprise Edition offers a powerful calendar with a spreadsheet of the same job information without retyping anything and instant access to the details of any job. As a multi-user system, changes made by one person are immediately accessible to everyone in the office, shop and in the field using mobile devices. Because it is an integrated solution, account information automatically shows up on jobs and quotes. Also, changes to the jobs show up on the calendar instantly, and there is no need to duplicate data.

With everything from a powerful calendar and quoting system, through sophisticated business reporting, Moraware JobTracker allows users to save time and get organized.

Moraware JobTracker Standard Edition eliminates the time fabricators and installers waste on scheduling and paperwork. JobTracker Standard Edition is scheduling and job management software that uses a simple Web browser-based interface. It can be configured to manage the variety of jobs done by stone fabricators and other specialty contractors.

JobTracker Standard Edition is a multi-user system, where changes made by one person are immediately accessible to everyone in the office, shop and in the field using mobile devices. Dealers, builders and other customers may also log into JobTracker to see dates and other information about their jobs.

Moraware JobTracker Standard Edition users who want to integrate their quoting, purchasing and inventory can upgrade to JobTracker Enterprise Edition.

Moraware JobTracker Basic Edition is affordable and easy-to-use scheduling and job management software designed for businesses that want to eliminate the time they waste scheduling and looking for paperwork.

As a subscription service, JobTracker Basic Edition lets customers get started without installing any software, and no upfront purchase is required. There are no long-term contracts, and Moraware offers an unconditional 90-day refund policy.

The Synergy Inventory software tracks each slab of material from the time is it photographed at the Pathfinder Digital Photo station until is has been processed. The remnants are barcoded and filed in the inventory database. This software gives fabricators the ability to easily store and manage remnant pieces digitally without retaking a photo.

Users just have to print a new barcode tag and place on the remnant. The barcode stores remnant information, including the slab bundle, slab block, size of the remnant, color and thickness, among other details.

Another feature of the Synergy Inventory software lies in its reporting capabilities. Users can create user-defined inventory reports, which can be easily exported into an Excel file. The Synergy Inventory software allows fabricators to sort inventory through a variety - or a combination of - 12 different filters.

Diversified Shop/Field Product

Akemi’s new color-matched polyester adhesive kit provides the stone professional/installation professional with 15 pre-mixed Mixbond adhesives that are used in combination with each other to match virtually any color of natural and engineered stone, the company reports. With a solid pre-mixed base color, the professional is able to easily adjust for shades without having to use coloring tints. Refills are also available.

According to Bellinzoni, StonEpoxy hardens in about three hours, will not shrink and can be used in temperatures between 41 and 75 degrees F.

E-Z Bracket attaches to the cabinet with wood screws as well as to the countertop with impact-absorbing adhesive caulk or silicone. It is made to accommodate virtually any dishwasher on the market, and it may be installed prior to or after countertop installation. There is no need for the dishwasher to be on site, due to the multiple attachment locations. Countertop installers need only install the bracket across the top of the dishwasher bay, flush tabs to face of cabinet and install the screws provided with the bracket at each end.

- Engineered dust control systems

- Material handling

- Traffic

- Electrical

- First aid

- Ergonomics

- General shop safety

- Personal protective equipment, including, hand, respiratory, eye, head, hearing and foot protection

“This catalog is the culmination of a tremendous effort by GranQuartz to compile a comprehensive, best-in-class safety program,” said Dave Flanagan, Product Manager for GranQuartz. “GranQuartz built this program around key suppliers that we partnered with because of the leadership within their respective product categories, the innovation of their product lines and the commitment to safety evident in the engineering, production and quality control of their industry-leading, high quality safety solutions.”