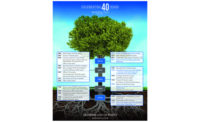

The company celebrates a distinguished history marked by some of the industry’s most significant technological advances and a specialized organizational design. Industry changing worldwide patents have been issued for the P.B.S.® diamond brazing system and, most recently, for the apparatus that is designed and engineered to produce VFlex™ superabrasive grinding wheels. Four decades of patents and developments showcase Abrasive Technology’s innovative expertise.

Dedicated to a culture of learning, growing and being curious, Abrasive Technology has set the standard in the industry by developing and implementing a Process Centered Organization. This flat organizational design focuses on individual accountability and associate development programs where team members are committed to “Shaping the World Around Us.”

The company’s successful implementation of this design was featured in the book “Transforming Your Leadership Culture,” authored by South Carolina-based Center for Creative Leadership (CCL), after an extensive 10-year research program on Process Centered Organizations.

Founded in 1971 by four entrepreneurs in a small, single facility in Columbus, OH, Abrasive Technology’s original mission was to design, develop and manufacture state-of-the-art superabrasive tools for dental and industrial applications. Today, that goal has been realized and greatly expanded. Currently headquartered in Lewis Center, OH, the company has facilities in the U.S., United Kingdom, Canada, Mexico, Singapore, Spain and Poland -- serving a multitude of industries, including aerospace, automotive, medical, electronics, stone, general industrial and more.

“We are honored to have stayed true to our entrepreneurial foundations and our innovative spirit; while growing into a dynamic worldwide organization,” said Loyal M. Peterman, Jr., President and Founder of the company. “We continue to embrace the opportunity to develop products and associates who can help ‘Shape the World Around Us’ while manufacturing results-driven products for our customers’ specialized application needs.”