In business since 1997, K & D Counter Tops of Trenton, IL, has grown from a laminate shop to a full-scale stone operation.

When it was founded, K & D Counter Tops of Trenton, IL, specialized in the production of laminate countertops. But as time passed, the company evolved to the point that it is now primarily a stone fabrication shop. And despite a slowing economy, K & D Counter Tops has held its ground and has continued growing by diversifying into other segments.

“We started in 1997 as a laminate shop, but knew from the beginning our focus would be on more premium surfaces,” said John Daiber, who owns K & D Counter Tops with partners David Kapp and Troy Kapp. “While in college, I got my start sweeping floors for a small laminate shop. I gradually worked my way up within the company and after graduating managed their operation. I was starting to see a demand for premium surfaces and after failing to convince the owner to expand his operation I decided to branch out on my own.

“At the same time, my brother-in-law was in the cultured marble business and was considering his own business venture,” Daiber went on to say. “We decided to partner and focus on laminate, and then we quickly got into the solid surface business becoming a Certified Corian fabricator. We grew solid surface into a pretty nice business, but we could see the consumer’s interest beginning to move toward stone and in 2004, we got into the stone business by cutting Zodiaq for Lowe’s.”

The company’s 20,000-square-foot fabrication facility houses two Titan 1800 and two Titan 1600 CNC stoneworking centers from Park Industries of St. Cloud, MN.

Since its beginnings, the company has remained in the same location. “We expanded four times,” said Daiber. “We currently have about 20,000 square feet of fabrication space and 65 employees.”

The shop is equipped with two Titan 1800 and two Titan 1600 CNC stoneworking centers, a dual-table Fusion 4245 bridge saw/waterjet and a Pro-Edge polishing line - all from Park Industries of St. Cloud, MN. Additionally, a Marmo Meccanica edge polisher is also used in the production process.

The majority of the tools and accessories utilized during fabrication are purchased from GranQuartz of Tucker, GA, including ADI CNC tooling. The CNC machines are equipped with vacuum pods from Blick Industries of Laguna Beach, CA.

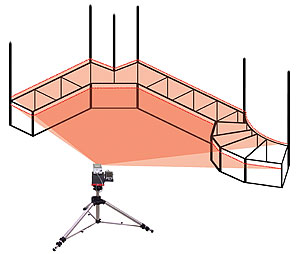

K & D Counter Tops has four templators who use LT-55 Laser systems from Laser Products of Romeoville, IL. “We tried virtually everything [for digital templating],” explained Daiber. “We used PhotoTop for a long time, but have made the switch to the Laser system. Laser Products really worked with us and listened to some things we wanted changed. It has been a very good partnership.”

The CNC machines are equipped with ADI tooling from GranQuartz of Tucker, GA, and vacuum pods from Blick Industries of Laguna Beach, CA.

Being 30 miles from downtown St. Louis, MO, K & D Counter Top’s market spans central and southern Illinois as well as the eastern part of Missouri. “Residential was our main focus until early 2009 when the economy started to soften,” said Daiber. “We looked for other avenues to continue our growth, and expanded our commercial branch.

“Right now, we are beginning to see hopeful signs the economy is strengthening,” he went on to say. “It has been a roller coaster ride the last few years but through it all we’ve seen fairly consistent growth in our stone business.”

Recently, the company completed a lobby for a high-rise in St. Louis, which features large-format tiles of Carrara marble on the walls. “We are really excited about that,” said Daiber. “We are getting a lot of positive feedback and are looking forward to more opportunities in the commercial segment.”

K & D Counter Tops

Trenton, ILType of work: residential and commercial

Machinery: two Titan 1800 and two Titan 1600 CNC stoneworking centers, a dual-table Fusion bridge saw/waterjet and a Pro-Edge polishing line - all from Park Industries of St. Cloud, MN; a Marmo Meccanica edge polisher; tools and accessories, including ADI CNC tooling from GranQuartz of Tucker, GA; vacuum pods from Blick Industries of Laguna Beach, CA; and LT-55 Laser systems from Laser Products of Romeoville, IL

Number of employees: 65

Production rate: approximately 4,100 square feet per week, including all surfaces (laminate, solid surface and stone/quartz surfacing) of which 2,700 square feet is stone/quartz surfacing

A Fusion 4245 bridge saw/waterjet from Park Industries is also used during the production process to cut stone for residential projects as well as for the newly developed commercial division.

K & D Counter Tops has four templators who utilize LT-55 Laser systems from Laser Products of Romeoville, IL. “We tried virtually everything [for digital templating],” explained John Daiber, who owns the company with partners David Kapp and Troy Kapp. “Laser Products really worked with us and listened to some things we wanted changed. It has been a very good partnership.”

The company has expanded its facility four times since first opening its doors to accommodate its growth.

Being 30 miles from downtown St. Louis, MO, K & D Counter Top’s market spans central and southern Illinois as well as the eastern part of Missouri. “Residential was our main focus until early 2009 when the economy started to soften,” said Daiber. “We looked for other avenues to continue our growth, and expanded our commercial branch.”

Recently, the company completed a lobby for a high-rise in St. Louis, which features large-format tiles of Carrara marble on the walls.