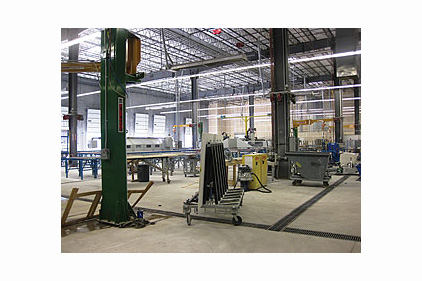

(This picture and the next) Barbosa Cabinets, Inc. runs a 66,000-square-foot countertop division out of its new facility in Lathrop, CA.

Started more than 30 years ago, Barbosa Cabinets, Inc. is a family-run business that prides itself on efficiency and outstanding customer service. From its humble beginnings as a cabinet shop working out of a 2,500-square-foot facility, the company has grown to include a full-scale countertop division, which operates out of a 66,000-square-foot plant in Lathrop, CA. Additionally, there is a 312,000-square-foot space that houses the company’s cabinet business and former countertop shops.

Barbosa Cabinets’ story began in 1978, when Armand Barbosa along with his two sons, Ed and Ron, founded the company to offer Old World craftsmanship to builders and homeowners throughout Northern California. Successful from the start, the company had outgrown its facility within three years. Continuing with its path of expansion, it opened a second facility that included a full-service finishing department in 1990, and in 1997, it further expanded into a third building to include a countertop division.

“The company started as a major cabinet subcontractor, and it really flourished and grew rapidly,” said Brian Towers, General Manager of the countertop division. “They started in solid surface and laminate, and quickly moved into stone.”

According to Towers, the company owners really take time to strategize and maintain a successful business. “The Barbosas are very focused on running an operation correctly,” he said. “They want it to run well and look good. The presentation of the facility is very important.”

Setting up a new countertop shop

At the time of Stone World’s visit, Barbosa Cabinets had recently moved its countertop division, which includes stone/solid surface and laminated plastic, into its new space. “We are set up for high production,” said Towers. “Right now, we are working at half capacity with four saws. We can grow to double that very quickly. The equipment here is well thought out, and the flow is excellent - all on a conveyor system.”Among the machinery in the new shop are a Yukon and a Yukon II bridge saw as well as a Velocity edge polisher - all from Park Industries of St. Cloud, MN; an AIM 2400 programmable CNC saw; three Intermac Master Stone CNC stoneworking centers equipped with the Terminator brand of tooling from Continental DIA Diamond Products of San Carlos, CA, and vacuum pods from Blick Industries of Laguna Beach, CA; a Stonecraft waterjet from Flow International of Kent, WA; and a Penta polishing machine and a Synthesis 12-head edge polishing station - both from Comandulli of Italy.

The saws are equipped with Terminator blades from Continental DIA Diamond Products, and Barbosa Cabinets also uses Terminator polishing pads and cup wheels. “The company has used Terminator blades before I even came here,” said Towers. “Continental also offers solutions. We rely on their expertise.”

An AIM 2400 CNC programmable saw, which is equipped with Terminator blades from Continental DIA Diamond Products of San Carlos, CA, is in place in the shop for stone countertop production.

A workstation is in place for handwork. Tools and accessories are purchased from Braxton-Bragg of Knoxville, TN, and National Abrasives of San Leandro, CA. Slabs are moved around the shop with Elephant cranes that use vacuum lifters from Woods Powr-Grip Co. Inc. of Laurel, MT.

“Our philosophy is that if you have the right equipment and the right people, you have the right products,” said Towers, adding that Barbosa Cabinets currently outputs 1,200 square feet of countertops a day. A total of 40% of its work is in natural stone, 25% engineered marble, 20% quartz surfacing and the rest is in solid surface and laminated plastic. The company works with engineered quartz from CaesarStone, Silestone and DuPontTM Zodiaq®, among others.

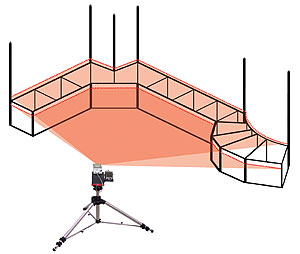

Presently, the countertop division includes 18 cutters, fabricators and polishers in the shop as well as eight two-man installation crews and sales/office staff totaling 48 employees. “We have three LT-55 Laser Templators [from Laser Products of Romeoville, IL] that we are going to start using this year,” said Towers. “Currently, we are cutting wood strips [for templating].”

A Yukon II bridge saw from Park Industries of St. Cloud, MN, is also used to cut slabs.

Marketing efforts

Towers explained that Barbosa Cabinets’ market currently spans a 100-mile radius. “We have the ability to go further,” he said. “We maintain a lot of builder business as well as commercial.”The company maintains an inventory of approximately 300 slabs. “I instituted the policy to hold inventory,” said Towers. “Bringing in inventory has helped us reduce material costs. It allows us to buy smarter and utilize remnants. [Also], we are batching now. We can project ahead and cut like-colored jobs and get a better yield.”

According to Towers, partnering with key suppliers has proven successful for the company. “Some suppliers will consider 90-day terms or consignment inventories with an agreement for quick inventory ‘turns’,” he explained. “This improves cash flow - especially with builders paying on a 60- to 90-day cycle.”

Another key to success for the company is that it offers a full-service experience to its customers purchasing staff and project managers. “We are a cabinet manufacturer and installer, so we can better control the sales of the countertops as well,” said Towers. “It works well for us. It gives our customers a lot of advantages if we are doing both.”

And to remain efficient, Barbosa Cabinets has developed its own software to track its jobs. “We can download information right from the purchase order to final drawings and track every part of job costs to stay competitive,” said Towers.

To ensure efficiency in the workplace, the company has plans to install a camera system in the new shop. “It doesn’t mean that we don’t trust our employees,” explained Towers. “It’s a great way to document safety issues, and it has also been known to increase production.”

Towers went on to say that many of the employees on staff have been with the company for over 20 years. “The Barbosas have always taken very good care of their people, despite difficult times,” he said.

Barbosa Cabinets, Inc.

Lathrop, CAType of work: primarily builder homes and commercial work

Machinery: a Yukon and a Yukon II bridge saw as well as a Velocity edge polisher - all from Park Industries of St. Cloud, MN; an AIM 2400 CNC programmable saw; three Master CNC stoneworking centers from Intermac America, Glass and Stone of Charlotte, NC; a Stonecraft waterjet from Flow International of Kent, WA; a Penta edge polishing machine and a Synthesis 12-head edge polishing station - both from Comandulli of Italy; two EnviroSystems from Water Treatment Technologies of Hampton, NH, two Quincy air compressors; Terminator CNC tooling, blades, cup wheels and polishing pads from Continental DIA Diamond Products of San Carlos, CA; vacuum pods from Blick Industries of Laguna Beach, CA; three LT-55 Laser Templators from Laser Products of Romeoville, IL; hand tools and accessories from Braxton-Bragg of Knoxville, TN, and National Abrasives of San Leandro, CA; vacuum lifters from Woods Powr-Grip Co. Inc. of Laurel, MT

Number of employees: 18 cutters, fabricators and polishers (countertop division), 8 two-man installation crews and sales/office staff totaling 48 employees

Production rate: 1,200 square feet of countertops a day

Other machinery in the shop includes a Stonecraft waterjet from Flow International of Kent, WA, which is ideal for cutting intricate stonework.

Three Intermac Master Stone CNC stoneworking centers - equipped with the Terminator brand of tooling from Continental DIA Diamond Products and vacuum pods from Blick Industries of Laguna Beach, CA - aid in the production of 1,200 square feet of countertops per day.

Barbosa Cabinets employs 18 cutters, fabricators and polishers in its countertop division.

Slab backsplashes are finished with a Penta edge polishing machine from Comandulli of Italy.

Hand tools and accessories that are utilized during the production process are purchased from Braxton-Bragg of Knoxville, TN, and National Abrasives of San Leandro, CA.

Water used during fabrication is recycled with two EnviroSystems from Water Treatment Technologies of Hampton, NH.

Partnering with key suppliers to maintain an extensive inventory has proven successful for the company.

Barbosa Cabinets inventory includes approximately 300 slabs. “I instituted the policy to hold inventory,” said Brian Towers, General Manager of the countertop division. “Bringing in inventory has helped us reduce material costs. It allows us to buy smarter and utilize remnants. [Also], we are batching now. We can project ahead and cut like-colored jobs and get a better yield.”

The company has eight two-man install crews, which service customers throughout the Northern California area.

Recently, Barbosa Cabinets invested in three LT-55 Laser Templators from Laser Products of Romeoville, IL, which will be used for measuring.