Nearly two decades ago, when the stonecutters at Owen Sound Ledgerock of Owen Sound, Ontario, Canada, learned that the company was making a serious investment in CNC mills and CAM (Computer Aided Manufacturing) software, the group concluded that their jobs were in jeopardy. In the end, however, the company reports that the new software and equipment have protected jobs by allowing it to produce more work of higher quality with its existing manpower.

Today, the stonecutters have a greater opportunity to perform challenging artistic work and are less burdened with the tedious and physically punishing work of manually roughing out pieces with air chisels and other impact tools prior to doing the finish work.

“Our CNC machines and CAM software - Mastercam X4 and Mastercam Art from CNC Software, Tolland, CT - have allowed us to grow tremendously in the architectural and dimensional stone business, which was not a part of the company until the early 90s,” explained Company Engineer Jim Stobbe. “Prior to that, we did more traditional building stone applications, such as hearths, mantles and patio squares. We still do these and do them well. However, growing the business into dimensional stone has opened up doors to huge projects for various universities and other prestigious organizations.”

Quarrying operations

Owen Sound Ledgerock operates a quarry abounding in high-quality limestone that dates back 450 million years. There are a variety of layers in the limestone that have different properties and colorations. These are removed from the ground in 12-ton blocks and then cut down to progressively smaller billets using saws that range from 3.5 meters to 3.5 inches in diameter.

These are the raw materials for a wide variety of end products, including rough landscaping stone, patio squares, countertops, cladding for building exteriors and intricate architectural details. The products are sold directly to key customers and through an extensive dealer network in Canada and parts of the U.S.

Jim Stobbe’s father, Harold, established Owen Sound Ledgerock 51 years ago, and Jim grew up around the business. Then he went off to college, ultimately becoming a manufacturing engineer working for Ford as well as a number of major automotive suppliers. When he returned to Ledgerock, his extensive experience with CNC manufacturing fit in well with the company’s computer automated manufacturing initiatives, which were already well underway.

Today, Ledgerock has 11 CNC machines used for cutting architectural details. It has a number of machines from Park Industries of St. Cloud, MN, as well as three Omag mills from Italy. For higher-precision work, the company has Haas VF9 and VF4 mills - equipment designed for conventional metalworking.

Stoneworking

Unlike metalworking, stone cannot be cut while using coolant, because coolant would stain the product. So Ledgerock has developed dry stone-cutting processes and tooling that cut the stone efficiently while contending with all of the powdery stone dust. Remarkably, the Haas machines have been running in this manner for 10 years without requiring major overhauls.

“How the stone was formed in the ground is an important consideration when applying the cutter paths to the stones,” Jim Stobbe explained. “You have to make sure you are taking advantage of that, both from the strength of the stone and ultimately what is exposed to the elements and its weathering. You want it to weather well so it does not pose any problems down the road. After all, we are making product that will be out there for hundreds of years in some cases.”

To program the CNC equipment, Ledgerock has five Mastercam X licenses (Mill, Lathe, Solids, Art and Design.) There are six users (including Stobbe) and they share access to the various seats on a first-come, first-serve basis over a network.

Two of the users are draftsmen on the front end of the process. They handle the modeling of projects, starting with designs imported seamlessly from AutoCAD. One is a highly experienced Mastercam user who serves as a teaching resource for the company. The other three primary users are in the shop. They use Mastercam to generate the toolpaths for cutting the various stone pieces using a computer-simulated CNC manufacturing environment.

As in metalworking, Mastercam is used to build a library of tools that are used in various cutting situations. However, the tools are typically circular, ranging from 80-mm tools with diamond edges up to circular tools 1.4 meters in diameter - a saw blade. If corners sharper than the radiused ones made by the circular tools are required, the stonecutters do it manually.

“The primary objective is to make as much of the product as possible on the CNC,” Stobbe said. “We still rely on the artistry of the stone carvers to go in and sharpen up the piece and give it that uniqueness that people are looking for. Typically, our customers want something that is a piece of art - not geometrically perfect. Finishing it by hand gives it character. Once they have the basic shape with Mastercam, setting out the proportions and the various elevations from the base height, then the stone carver can go in and add the detail that really brings it to life.”

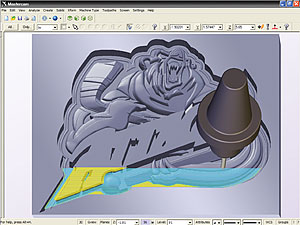

Recently, Ledgerock has been taking advantage of the Mastercam Art program to transform two-dimensional graphics such as photographs and drawings into three-dimensional surfaces. “With Mastercam Art, a stone carver can work with a pencil and a piece of paper and draw what he wants to create,” Stobbe said. “He can then scan the drawing and import it into Art, which will automatically create the desired toolpath.”

The process is very different from a straightforward laser etching. “Laser technology does a fantastic job of photo rendering, so you can see an image like a photograph,” Stobbe explained. “What we are doing with Art is making that photograph ‘pop’ by giving it the third dimension.”

One of the major advantages of this approach is that it strips a huge amount of labor content out of high value-added custom projects. To do this in the past, the programmer would have to create the toolpaths for all of these sculptured surfaces in Mastercam manually. “With the Art package, there are a variety of tools that automate a lot of the tedious work and significantly reduce the amount of time for creating these programs,” Stobbe said.

So Ledgerock is taking computer aided manufacturing in stone to places it has rarely gone before. For example, one of the most challenging applications the company has undertaken is the creation of three-dimensional rails for spiral staircases. Stobbe relied on his background in mechanical engineering and Mastercam’s CAD capabilities to create solid models of these complex geometries. This made it possible to eliminate discontinuities in the geometry, which made rails difficult to cut on the CNC equipment. Other tricks he uses with the software and tooling allow him to emulate 5-axis machining of these pieces on Ledgerock’s 4-axis equipment.

Compared to 10 years ago, when Ledgerock began its transition to computer aided manufacturing, Stobbe estimates that the company outputs five times more work with a comparable staff. Because of their increased productivity, the company has been able to retain its talented stable of stonecutters (a dying art) and high value-added dimensional stonework has become a significant profit center for the company.