Moscone Marble opened its doors in Vaughan, Ontario,

Canada in 1990. Today, the company operates out of a 63,000-square-foot

facility - complete with a stone gallery and designer showroom.

The shop is equipped with four Prussiani Energia Plus

CNC stoneworking centers.

“We started in a modest shop,” said Anthony Marrese, owner of Moscone Marble. “It was 5,000 square feet. There was one saw and a couple of workers. Since then we have expanded and moved a couple of times. Now we share a 63,000-square-foot facility with the tile company. We moved two years ago to our new facility, and both companies, tile and marble, have flourished with a designer tile and slab retail showroom.”

Primarily, Moscone Marble caters to the new construction market. “Our major business was and always is new construction,” said Marrese. “We do a lot of condos all around the Toronto area - downtown especially. We also do a lot of new [single-family] construction homes. We deal with a lot of kitchen fabrication companies and cabinet makers. On top of that, we have a terrific retail business.”

With a state-of-the-art facility, Moscone Marble

currently produces 100 kitchen and vanity tops per week. The CNC machines are

all equipped with tooling manufactured by Nicolai Diamant of Italy. “Nicolai

has an excellent quality product,” said company owner Anthony Marrese. “It is

long lasting and little to no hand touch up is required after the pieces are

finished.”

The Production Process

To maintain its high-quality production standards, the company’s fabrication shop is equipped with four Energia Plus CNC stoneworking centers from Prussiani of Italy and two bridge saws from Terzago Macchine Srl of Italy. The most recent addition to its line-up of state-of-the-art machinery is a New Champion 5 automatic saw with a conveyor belt from Prussiani.“This automated saw should increase cutting capacity to at least two times our production,” said Marrese, adding that his shop is the first in North America to use this machine. “Right now - between kitchen and vanities - we are doing 100 per week, which is equivalent to about 3,000 square feet.”

And despite the difficult economic times, business has remained steady for the company, according to Marrese. “This is our busiest year,” he said. “It really didn’t hit us. If anything, we have increased the amount of work we are doing.”

In addition to the large machinery, a variety of hand tools and accessories are also utilized in the production process. These are purchased through Advance Cutting of Richmond Hill, Ontario, Canada, and GranQuartz of Tucker, GA. Tooling used on the machines is manufactured by Nicolai Diamant of Italy. “Nicolai has an excellent quality product,” said Marrese. “It is long lasting and little to no hand touch up is required after the pieces are finished.”

At this time, Moscone Marble employs 50 people. “It’s a far cry from when we started 20 years ago,” said Marrese. “We only had two employees.”

The majority of the company’s market is in Toronto, but it also does some work in southern Ontario; Buffalo, NY; and Detroit, MI. The facility includes a slab gallery with approximately 1,000 slabs where customers can come to choose their material.

When looking towards the future, Marrese intends to focus on maintaining excellent quality. “Increasing production is also one of our goals,” he said. “The new machine will help us achieve that.”

Moscone Marble

Toronto, Ontario, Canada

Type of work: primarily new residential construction

Machinery: four Energia Plus CNC stoneworking centers and a New Champion 5 automated saw with a conveyor belt - all from Prussiani of Italy, two bridge saws from Terzago Macchine Srl of Italy, tooling from Nicolai Diamant of Italy, and hand tools and accessories from Advance Cutting of Richmond Hill, Ontario, Canada, and GranQuartz of Tucker, GA

Number of employees: 50

Production rate: 100 kitchen and vanity tops per week or approximately 3,000 square feet

The Prussiani Energia Plus CNCs allow the company to

maintain high-quality production.

Two Terzago bridge saws are also in place to cut

slabs.

The most recent addition to its line-up of

state-of-the-art machinery is a Prussiani New Champion 5 automatic saw with a

conveyor belt. “This automated saw should increase cutting capacity to at least

two times our production,” said Marrese, adding that his shop is the first in

North America to use this machine.

The shop includes a designated area for hand work.

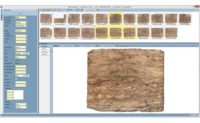

In addition to the fabrication shop, Moscone Marble’s

facility also includes a slab gallery where approximately 1,000 slabs are kept

in inventory.

The company also maintains a designer showroom where

customers can come to view stone samples.

The showroom was built two years ago when Moscone

Marble moved from a smaller space to its current facility.

Moscone Marble also produces custom work such as this

conference room table top.