Spaulding Fabricators Inc. operates out of a 13,000-square-foot facility in

Brick, NJ, which owner Stephen Spaulding built himself in 2000. Photos by Michael Reis

With a background in construction, Stephen Spaulding ventured into the fabrication business with his wife, Michele, in 1988. Specializing in solid surface products, Spaulding Fabricators Inc. was based in the driveway of Spaulding’s in-laws’ home in Bergen County, NJ. More than 20 years later, the company has significantly expanded - operating out of a 13,000-square-foot facility in Brick, NJ - and it fabricates both natural and engineered stone products for primarily the Southern New Jersey and Philadelphia areas.

“We are a family-owned and operated business,” said Spaulding, adding that the company is a member of the International Surface Fabricators Association (ISFA). “My father-in-law helped start the business. He was like a mentor to me. He had a lot of experience in manufacturing. We started with a saw and hand tools when we were doing Corian.”

Once the business was established and sales picked up, Spaulding Fabricators needed more work space. As a result, the operation moved to a facility in Englishtown, NJ, in 1990. Ten years later, the company had outgrown the new building, and an opportunity became available for Spaulding to buy property in an industrial park in Brick, NJ, and build his own facility.

“We built our building ourselves in 2000,” said Spaulding. “It took a year to complete it. I was renting a building nearby while it was being built, so I was able to go back and forth.”

To cater to both the solid surface and stone industries, the building is divided into two work areas. Additionally, it includes radiant heating throughout and is equipped with state-of-the-art machinery, which Spaulding carefully researched before making an investment. “I did some homework and learned a little bit from everyone,” he said. “I went looking at shops in Maryland and Pennsylvania. That’s why I bought what I did.”

The company’s most recent investment was a SawJet from

Northwood Machine Manufacturing of Louisville, KY.

Investing in technology

In 2002, Spaulding invested in a Northwood 158 CNC stoneworking center from Northwood Machine Manufacturing in Louisville, KY. “I have the eighth one they ever built,” said Spaulding. “It’s unbelievable. [Due to its large size], we had to rip a wall out to get it in the shop.”A few years later, the company purchased a Northwood 138 CNC, and most recently, it added a Northwood SawJet several months ago to its lineup of equipment. “Their service is unbelievable,” said Spaulding. “Nothing can compare to the SawJet. It does a great job. You can saw by yourself or waterjet by yourself or do a combination.” The SawJet is equipped with a StreamlineTM SL-V50 Plus pump from KMT Waterjet Systems of Baxter Springs, KS.

Among other machinery in the shop is a Yukon bridge saw and Fastback flat-edge polishing machine - both from Park Industries of St. Cloud, MN, and a Gorbel 2,000-pound overhead crane. Additionally, a Hy-Pack water treatment system from Beckart Environmental, Inc. of Kenosha, WI, was put in place four years ago to recycle water used during the fabrication process.

Spaulding Fabricators also utilizes vacuum lifters from Wood’s Powr-Grip of Laurel, MT, sink hole saver edge protectors from Omni Cubed of Placerville, CA, and it purchases its hand tools and accessories from companies such as GranQuartz of Tucker, GA, and Stone Boss of Fair Lawn, NJ.

Currently, the company consists of a staff of 16 employees, which includes six shop workers and two install crews with two workers in each. An LT-55 Laser Templator from Laser Products Industries of Romeoville, IL, is used for templating. “I bought one of the first ones,” said Spaulding. “That company has been really good to work with.”

“Nothing can compare to the SawJet,” said Spaulding.

“It does a great job. You can saw by yourself or waterjet by yourself or do a

combination.”

Marketing its products

A total of 40 percent of Spaulding Fabricators’ work is in natural stone, while the other 60 percent is in engineered stone products such as CaesarStone, Silestone and IceStone. The company purchases its stone material from about five local distributors.Marketing to New Jersey, Eastern Pennsylvania and some areas of New York, including Staten Island, Spaulding Fabricators caters to both the residential and commercial sectors. On average, 10 to 12 stone jobs are typically in production at one time. Recent work includes a stone fireplace surround for a project featured in the DIY Network television show “Man Caves” and a bar top for Jenkinson’s bar in Point Pleasant, NJ. The company also supplied 80 slabs of DuPontTM Zodiaq that were employed as wall panels and a staircase in the Philadelphia airport.

And although Spaulding reports that business is just starting to pick up a little, he stresses the importance of finding new ways to sell products. He explained how he and his staff dedicated time to organizing all of its leftover stone pieces so that builders and homeowners can easily sort through the selection. “We started putting signs on the road saying ‘remnant sales’,” he said. “Organization is key. Now I can see exactly what I have.”

Spaulding Fabricators Inc.

Location: Brick, NJType of work: residential and commercial processing of stone and quartz surfacing

Machinery: a 158 CNC stoneworking center, a 138 CNC stoneworking center and a SawJet - all from Northwood Machine Manufacturing in Louisville, KY, a StreamlineTM SL-V50 Plus pump from KMT Waterjet Systems of Baxter Springs, KS, a Yukon bridge saw and Fastback flat-edge polishing machine - both from Park Industries of St. Cloud, MN, a Gorbel 2,000-pound crane, a Hy-Pack water treatment system from Beckart Environmental, Inc. of Kenosha, WI, vacuum lifters from Wood’s Powr-Group of Laurel, MT, edge protectors from Omni Cubed of Placerville, CA, hand tools and accessories from GranQuartz of Tucker, GA, and Stone Boss of Fair Lawn, NJ, and an LT-55 Laser Templator from Laser Products Industries of Romeoville, IL

Number of employees: 16, including six in the shop and two install crews of two men each

Production rate: 10 to 12 stone jobs per week

The SawJet is equipped with a StreamlineTM SL-V50 Plus

pump from KMT Waterjet Systems of Baxter Springs, KS.

The fabrication facility also houses two Northwood CNC

stoneworking centers.

A Yukon bridge saw from Park Industries of St. Cloud,

MN, is utilized to cut slabs during the production process.

A Park Industries Fastback flat-edge polishing machine

is used for polishing the edges of countertops.

A Hy-Pack water treatment system from Beckart

Environmental, Inc. of Kenosha, WI, was put in place four years ago to recycle

water used during fabrication.

Slabs are lifted with vacuum lifters from Wood’s

Powr-Grip of Laurel, MT.

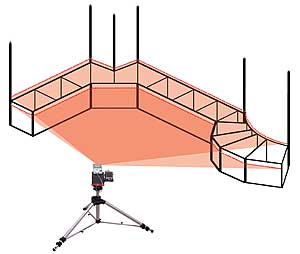

An LT-55 Laser Templator from Laser Products

Industries of Romeoville, IL, is used for templating. “I bought one of the

first ones,” said Spaulding. “That company has been really good to work with.”

A total of 40 percent of Spaulding Fabricators’ work is in

natural stone, while the other 60 percent is in engineered stone products such as

CaesarStone, Silestone and IceStone.

The staff at Spaulding Fabricators dedicated time to

organizing all of its remnants so that builders and homeowners can easily sort

through the selection.

The company’s market spans across New Jersey, Eastern

Pennsylvania and parts of New York, including Staten Island.