The Stone Fabricators Alliance held its first

“Mega-Workshop” in the St. Louis suburb of Collinsville, IL, from October 7 to

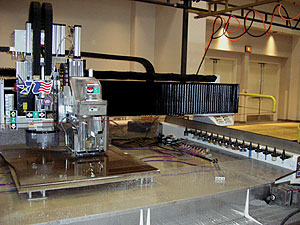

9. Throughout the event, large-scale machinery was in operation on the show

floor, processing actual kitchen projects.

For several years, the Stone Fabricators Alliance (SFA) has been conducting workshops for its members and guests at fabrication shops around the country. From October 7 to 9, the SFA expanded on that model by holding its first “Mega-Workshop” in the St. Louis suburb of Collinsville, IL.

The event included a full range of stoneworking machinery and other technology in operation on the show floor, and actual kitchen jobs were templated and processed over the course of the event. These finished kitchens went to homes through the local Habitat for Humanity charitable initiative. A total of four granite kitchens were fabricated for St. Louis area homes, and the “Habitat Restores” initiative also received a large quantity of finished tops for resale. In all, more than 40 slabs were cut, and the edges finished and polished into different configurations for demonstration purposes.

In terms of education, a range of opportunities were in place, ranging from hands-on education to classroom sessions. In addition to showcasing the machinery and tooling in action for attendees, the SFA MegaWorkshop also included a demonstration where slab bundles were unloaded from a container using a forklift, demonstrations of digital templating technology, seam-setting products and more.

Show managers reported an average attendance of 300

people per day, and the fabricators who attended the event praised the quality

of the exhibitions.

Show managers reported an average attendance of 300 people per day, and the fabricators who attended the event praised the quality of the exhibitions. Specifically, they cited the demonstration of machinery, tooling and other technology in “real-life” situations and the ability to test products on the show floor.

By using the equipment for actual cutting and routing

operations, the event also allowed attendees to gauge the performance of

various stoneworking tools and accessories, such as Terminator blades and CNC

tooling from Continental Diamond Products.

Additionally, suppliers of tooling and accessories

were able to showcase their products in action within “The Cage,” a dedicated

area where attendees could actually use and test products from the sponsors in

attendance.

Suppliers of tooling and accessories from around the U.S. and beyond

were on hand in Collinsvillle.

Among the machinery innovations on display, CMS North

America showcased its Vertical Nesting Technology for CNC machinery. The system

allows various workpieces to be automatically raised from the table for

processing, and it is shown here on the CMS UniMax.

Complementing its educational seminar on direct

importing, the Stone Fabricators Alliance Mega-Workshop featured a

demonstration where slab bundles were unloaded from a container using a

forklift.

In a creative marketing initiative, CMS North America

also utilized its UniMax CNC stoneworking center in a role as “bartender” for

its Happy Hour festivities at the close of the Mega-Workshop.

Session Summary: Importing and Buying Materials

Among the educational sessions in place at the SFA MegaWorkshop, an open forum on Importing and Buying Material was hosted by the following industry experts:- Dan Riccolo, Morris Granite, Morris, IL

- Miles Crowe, Crowe Custom Countertops, Acworth, GA

- Eric Rolseth, Centerpiece Surfaces, Inc., Elk River, MN<

An open forum, “Importing and Buying Materials,” was

led by (pictured from left): Eric Rolseth of Centerpiece Surfaces, Inc., Dan

Roccolo of Morris Granite and Miles Crowe of Crowe Custom Countertops.

How do you get started, and what are the benefits of importing directly?

Crowe: As our shop grew, it just made sense. For us, it wasn’t just a matter of getting a better price, but avoiding mismatched slabs of the same material. When you buy a bundle of one material, you know that the slabs should all look the same. We are cutting 40 to 50 kitchens per week, and that was important for us.Rolseth: We looked at our sales versus our costs, and it just made sense for us. A total of 50 percent of our sales dollars were spent on granite, and it was the biggest hole we had. The second was labor.

We looked on the Internet and in Stone World Magazine, and we started calling companies on our own. We went to Cachoeiro in Brazil, and at first, they couldn’t believe that we weren’t with anyone. We buy about $900,000 worth of material, and it has saved us 68 percent on material costs.

What about the cost factor of keeping a material inventory?

Crowe: You definitely tie money up. We have 600 to 800 slabs in stock.But we didn’t start doing it because we had extra money lying around. We did it because the numbers made sense. Also, as a retail operation, our inventory is a sales tool for us. If you end up selling customers somewhere else to look at slabs, we have found that 58 percent of the time, they don’t come back. By maintaining inventory, we keep control of the process.

Riccolo: If you look at the savings versus the costs, a savings of 33 percent is going to be better than any type of interest you will get out there. As far as insurance goes, that inventory will be insured if it is within 500 feet of your property.

How do you know if you are carrying the right materials for your market?

Riccolo: Not all inventory is perfect, but people have their own tastes. I am amazed at what people are drawn to. There are some beautiful stones out there in two- and three-lot bundles.With staples, we have bought them at times to help fill a container. But it is really not worth it to fill a container with staples, especially when you consider that your trip to Brazil costs around $3,000.

Crowe: Sometimes you can make a deal on just one color if it appeals to your market. Going to Brazil opened my eyes to how the process works. There are many different sizes of processors, from small factories to really large plants.

Are there other ways of importing?

Crowe: We also import through local distributors. They didn’t necessarily want to do it at first, but then they saw that I was serious and would be importing either way.Importing through a distributor was attractive to me because I was afraid of the risks. We all saw a container loaded right here at the show, so you can see the risks involved.

The savings wasn’t the same as buying [completely] direct, but the distributors deserve to get paid for their work, and I avoid the risks.

Riccolo: Another option is to buy multiple bundles, but then spread out the shipments - something like six bundles in six months.

Crowe: The important thing is to have a contact at the source so you are protected. You have to find the right factory, and groups like Brothers in Granite [a sourcing agency in Brazil] can assist you with that. They will go to the factories and get you the deal you are looking for. You will pay for that, but that’s why they’re in business.

Roselth: We have bought through Brothers in Granite, and it is important to understand that there are different levels of “buying direct” - factory, agent, broker and so on.

It is important to be a good customer. Some factories will try and show you their rejects, but when they see you are for real, some factories are great to work with.

We pay CAD - Cash Against Documents - and not terms.

Riccolo: We also pay CAD, by choice, for a price advantage.

Crowe: If you’re willing to pay and you have cash in hand, you can buy one container for a better price than a company that is buying in volume, but is in debt.

You’re not actually handing over cash, but you negotiate the price of a container, and they send you a pro forma invoice. You pick the stone before it is packed and on the water, and you see all of the photos and get the slabs numbers, etc. Then you send the money when you see the Bill of Lading that the stone is on the water.

Are you ever surprised with what you received?

Crowe: Once we received a stone that was half gray and half orange, with purple spots. We were supposed to pay $7/foot for it, and we ended up paying $4.75/foot. To our surprise, it sold within three weeks. People loved it for some reason.But overall, you have to build relationships, so people know your expectations and they know what you call “first quality.”

What about breakage?

Rolseth: We actually pay to have our material unloaded and delivered to our door on A-frames. It costs about $900 per container, but it is worth it.Riccolo: We pay marine insurance, and it is $140 per container. It is important to remember that if something breaks, it won’t be a couple of bundles. You will end up with a container of broken pieces. Our insurance covers the material on the water, at the receiving port, in the rail yard and on the train to Chicago.

Rolseth: It is very important to buy insurance. Brothers in Granite always has insurance on their invoices, but some don’t.

Riccolo: If you end up with a claim, you need to photograph it and have a marine surveyor come in and look at it. It is hard to report the claim yourself.

In most cases, though, most factories don’t want to steal $20,000 from you [by sending bad/broken material]. They’d rather earn $100,000 from you.