At a recent Stone Fabricators Alliance (SFA) Workshop,

veteran stone fabricators discussed using CNC and digital technology for

smaller “microshop” operations as well as large-volume production. To showcase

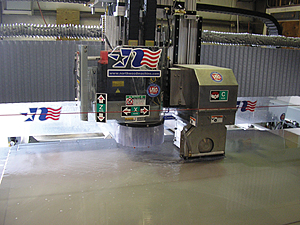

microshop production at the workshop, a Northwood SW138-UFC Ultimate FabCenter

was brought in to demonstrate how small-scale fabricators can utilize a single

CNC machine for both cutting and routing needs.

transcribed by Michael Reis

When CNC technology was first introduced to the stone industry, a common thought was, “When will my volume reach the point that I will need this technology?” Today, while large-scale operations are continuing to advance their utilization of CNC equipment, smaller-volume fabricators are also finding that CNC and digital technology can be the central component of their process.

At a recent Stone Fabricators Alliance (SFA) Workshop, two veteran stone fabricators presented both sides of the CNC spectrum. Scott McGourley from Kasco Stone of Tampa, FL, represented smaller “microshop” CNC/digital production, while Miles Crowe of Crowe Custom Countertops of Acworth, GA, discussed large-volume production using CNC technology.

McGourley began his presentation on microshop production with an explanation of how many shops are initially formed. “Most people start with a rail saw or a bridge saw and then figure it out,” he said. “We started manual, and I was never able to do enough to make the profit that I wanted while also not doing hack work. Then I read about a producer in Norway who was cutting slabs on a four-axis machine. He was a one-machine shop, and he was making it work.”

According to McGourley, a microshop is small in terms of size as well as production rate, but it is equipped with CNC and digital technology. “I consider a microshop to have 5,000 square feet of space or less, to have two to four employees and to produce 500 square feet or less per week. I personally do two slabs a day to make 400 square feet per week,” he said. “You need a digital cutting solution and digital renderings, and you are bringing everything down to the minimum. Just having a CNC router without a separate bridge saw is not a digital cutting solution. You still would need a saw man, so you are still dependent on manual labor. If you’re a small manual shop with three workers, it can be crippling if one guy doesn’t show up for work. Meanwhile, a machine is steady in its performance and the time to complete a task, so the level of quality and costs are maintained.”

At the presentation, Scott McGourley from Kasco Stone

of Tampa, FL (left), represented smaller “microshop” CNC/digital production,

while Miles Crowe of Crowe Custom Countertops of Acworth, GA, discussed

large-volume production using CNC technology.

Addressing the investment and costs of CNC technology, McGourley explained how a microshop can actually lower its monthly outlay. “Looking at tooling costs, we all know that CNC equipment is costly, but my tooling costs went through the floor,” he said. “We only purchase CNC tooling and a new saw blade once in awhile. A set of CNC tools is $3,000 or even a little less, but they last forever when you’re only doing 400 square feet per week. Our electricity costs have gone up, but our monthly outlay has gone down overall. A CNC is a lot of money on the initial investment, but when you look at our monthly outlay, it begins to make sense. You also have growth options. You cannot seriously do volume in a manual operation, but going from a microshop to a volume shop is possible with the addition of a digital cutting solution. Of course, a breakdown is very bad when you’re completely relying on one machine, so this is why finding a company with good service is key. You also have to pick the right machine for the right situation. This [Breton Fabcenter] is my solution.”

Kasco Stone utilizes a Breton Fabcenter for its

routing and cutting operations, and it averages 400 square feet of production

per week.

photo courtesy of Breton

photo courtesy of Breton

The process at Kasco Stone also allows McGourley to work directly with his customers. “In a microshop, the owner controls the quality. I am the templater right now, and that allows me to control the process,” he explained. “Digital renderings allow you to show the kitchen to the customer before cutting. It is also a way to check for errors. The customer might say that the sink is wrong, or that there are three faucet holes instead of two, or something like that. You cannot let the customer sit down and ‘design’ the kitchen, however, because they will sit there all day tweaking everything. If they want that, we offer the design option for $25 an hour.”

McGourley also stressed the need for a digital

rendering program in a microshop operation.

photo courtesy of Breton

photo courtesy of Breton

At the time of his presentation, McGourley said that his company is booked two months in advance. “We are now at the point where we can pick which customers we want to work with, because a small volume of work sustains our business model,” he said. “We can also select customers who are willing to pay higher margins for quality and service. We are not dependent on the customers who are comparing you to the guy down the street charging $29 per foot.”

After establishing itself as a small, manual shop,

Crowe Custom Countertops invested in a CNC stoneworking center from Northwood

Machine Corp. to reduce the shop’s reliance on manual labor. However, the

shop’s volume quickly grew after the investment.

Speaking on the operations at Crowe Custom Countertops, Crowe began by saying that he began as a much smaller shop. “I never planned on being a production shop,” he said. “We were doing two kitchens per week seven years ago,” he said. “And now we are doing 40 kitchens per week.”

Initially, Crowe invested in a CNC stoneworking center from Northwood Machine Corp. as a way to reduce his shop’s reliance on manual labor. “As we grew, I got tired of people always asking for a raise,” he said. “You sort of expect to be able to get rid of everyone when you invest in CNC, but we were getting more and more work, so we kept everyone on.”

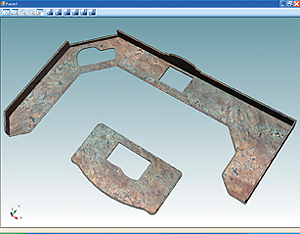

The next investment for Crowe Custom Countertops came

in November of 2007, when it added a dual-table SawJet from Northwood, which

provided the shop with a digital cutting solution. “When we first added the

SawJet, we were cutting with an old saw that didn’t even have a tilting table,”

Crowe said. “Now with the SawJet in place, we don’t even have any layout time.

It is all done digitally. It has increased our yield on slabs by about 10%

across the board, and it has also reduced our hand fabrication tremendously.”

With this new business model in place, Crowe’s sales techniques had to change as well. “We had to find the volume and devise creative ways to sell,” he said. “We also were able to find wholesale customers. I knew that I could produce granite cheaper than 75% of the shops out there, and once we got people to understand that, we could be successful. We also took over two shops, so we picked up their volume as well.”

The Northwood SawJet utilizes a waterjet pump and

cutting nozzle from KMT Waterjet Systems of Baxter Springs, KS.

Ultimately, Crowe said that the shop succeeded because it had the technology in place to set it apart from heavy competition in the Atlanta area during a down economy. “By having the SawJet and CNC, it turned out to be the best decision I ever made,” he said. “Atlanta has gone down from 300 shops to 150, but the last two years have been awesome for us. We have great opportunities in terms of purchasing material as well as not having downtime. We bought the first CNC when we were at 700 square feet of production per week, and now we are booked out for six weeks and can do 500 square feet in a shift.”

“We have a digital sales, templating, information flow

and fabrication, and we have the Moraware JobTracker system in place to keep

track of everything.” said Crowe.

For Crowe Custom Countertops, the investments ultimately presented the company with an opportunity to expand in size and scope. “My philosophy is based on growth,” he said. “We’ve grown because we were forced to grow and we had the capacity to do it. But there is a point of diminishing returns - for example, when overtime or Saturdays come into the equation to keep up. Also, selling the jobs comes with a cost. We now have four polishers working with us, and we also added a shop foreman and a quality control specialist.”

With a relatively large staff in place on the shop floor, Crowe said it is important that everyone is certain of all the specific details on a job. “No one in the shop can make a decision or an assumption on something,” he said. “If the type of radius isn’t listed, they need to go look it up rather than decide on their own. We have a digital sales, templating, information flow and fabrication, and we have the Moraware JobTracker system in place to keep track of everything.”

Crowe Custom Countertops also completes “fab-only” work for outside companies. “Everything is sent around digitally, and your quality-control manager is key,” Crowe said. “Approximately 40 to 45% of our work is fab-only on a square-foot basis. Of course, the revenue from fab-only is less than that, but that’s the percentage that goes through the shop.”