Originally established as a solid surface fabricator,

Surface Products of Cornelius, NC, expanded into quartz and natural stone. In

addition to residential stone processing, it has also made inroads into the

commercial sector.

Located in Cornelius, NC, and serving the Charlotte region and beyond, Surface Products began as a solid surface processor and ultimately began processing quartz and natural stone - including a high volume of countertops for production builders. Today, it uses that same lineup of machinery - including CNC technology - to fabricate stone for a range of projects in the commercial sector.

The company, which is a member of the Artisan Group of stone fabricators, processes natural stone as well as Corian Solid Surface, Heritage Wood, CaesarStone, DuPont Zodiaq, Cambria and other materials.

A primary piece of equipment in the shop is a Destiny

CNC stoneworking center from Park Industries of St. Cloud, MN. The machine

features laser projection to assist with pod placement.

In selecting machinery for stone processing, Lancto consulted his colleagues in the solid surface trade who had also expanded. “I was the original Founding President of ISSFA [the International Solid Surface Fabricators Association] and I had friends within the industry that already made the jump over to stone, so I had a lot of help in that regard,” he said.

Stone is maneuvered around the shop using a Gorbel

overhead crane system, which is equipped with Manzelli vacuum lifters from

GranQuartz of Tucker, GA.

In addition to the Destiny CNC, the stoneworking shop at Surface Products features a Park Yukon bridge saw for slab cutting and a Park Velocity edge processor, which can work pieces ranging from 2 to 12 feet in length and 4 to 12 feet in width. Stone is maneuvered around the shop using a Gorbel overhead crane system, which is equipped with Manzelli vacuum lifters from GranQuartz of Tucker, GA. Jobs are templated using LT-55 laser templating technology from Laser Products of Romeoville, IL.

The company has specially outfitted trucks for

carrying finished work to the jobsite.

The company employs between 40 and 45 workers, depending on the workload at a given time, and many are cross-trained to work in either the solid surface or hard surface shop. When bringing in new employees, the company has established a training program to help workers learn the trade.

Speaking on challenges in the marketplace, Lancto said that it is critical to educate customers - in the residential sector as well as commercial clients. “The biggest challenge is having customers understand the product,” he said. “On the commercial side, most architects don’t realize the limitations of the product. On the residential side, customers don’t understand the variations within a stone or the seam placement. So there is a learning process on every job.”

Sidebar: The Artisan Group

Surface Products is part of the Artisan Group, a national organization of independent granite fabricators that have joined together to offer the Artisan StoneTM Collection, the first and only brand of granite wholly owned by Artisan Group, which has a comprehensive lifetime warranty. The group also offers Heritage Wood TM countertops and Kohler sinks and faucets.“I was a founding member of Artisan,” said Jon Lancto of Surface Products. “We are getting close to 40 fabricators from across the country. It has become a great ‘best practices’ group. We trade a lot of information because we are all working towards the same goal in non-competitive situations.”

Group members average more than 20 years of fabrication experience in the countertop industry. Moreover, all Artisan Group members have achieved - or have begun the process to achieve - full accreditation with the Marble Institute of America. The group is among the first granite fabricators in the world to be working towards this distinction. Artisan Group also provides a complete line of granite care products including: FirstlineTM Sealer, FirstlineTM Clean & Restore and FirstlineTM Shine.

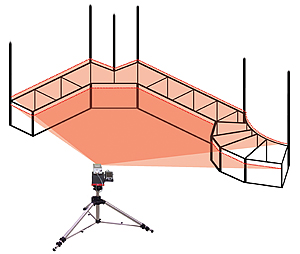

Jobs are templated using LT-55 laser templating

technology from Laser Products of Romeoville, IL (an example of which is

pictured).

Sidebar: Surface Products

Cornelius, NCType of work: Fabrication of stone, quartz and solid surface products for the residential and commercial sector, including healthcare facilities

Machinery: Destiny CNC stoneworking center router with laser production from Park Industries of St. Cloud, MN; Park Yukon bridge saw; Park Velocity edge processor; Gorbel overhead crane system with Manzelli lifters from GranQuartz of Tucker, GA; LT-55 laser templating technology from Laser Products Industries of Romeoville, IL

Number of Employees: 40 to 45 (including solid surface)

Production Rate: 12 to 15 kitchens per week, plus a range of commercial projects

Advanced technology in the shop allows Surface

Products to process a wide variety of countertop shapes.

Additional Photos

The company has processed countertops for a range of

kitchen styles and layouts.

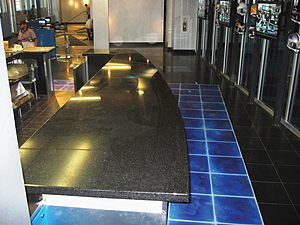

Among its high-profile projects, Surface Products

fabricated countertops for the “Gridiron Club” inside Bank of America Stadium,

home to the NFL’s Carolina Panthers.