In operation for more than 40 years, Marmi Graniti

Favorita of Vicenza, Italy, now specializes in unique materials, which it

exports to a worldwide client base.

Founded by Orazio Conterno more than 40 years ago, and still operated by the Conterno family today, Marmi Graniti Favorita of Vicenza, Italy, initially quarried and processed marble - typical of the stoneworking operations of its time. Over the years, it expanded into the production of finished and semi-finished products in granite and other stones. Today, the company specialty is processing one-of-a-kind materials. It works with a range of unique materials from around the world, including a broad variety of onyx slabs as well as unique materials in granite and sought-after white marbles such as Calacatta.

Currently, 70% of Marmi Graniti Favorita’s production is granite, and 30% is onyx and marble.

The production process begins with blocks, which are

brought in from quarries around the world.

Raw slabs are then calibrated on an 18-head honing line from Simec, and once calibrated, they are delivered to the resin-treatment line as needed. This line includes large-scale units from Simec that allow for treatment of many slabs at once. The calibrated slabs first enter a drying unit, and then resin products from Tenax of Italy are applied either automatically or by hand, depending on the material being processed. The resin-treated slabs are then placed in an automated curing unit that can accommodate 40 slabs at once, and after the curing process is complete, the slabs receive their final polish on one of two Simec polishing lines.

Blocks are processed on one of four Italian-made

gangsaws, including three from Barsanti and one from Simec.

Additionally, the plant uses a new Tenax resin technology, Glaxs, which protects the material from yellowing when exposed to UV rays. Tenax has also developed a special formulation of Glaxs for softer stone materials.

In all, approximately 40% of the slab material processed at Marmi Graniti Favorita is treated with resin.

Raw slabs are then calibrated on an 18-head honing

line from Simec, and once calibrated, they are delivered to the resin-treatment

line as needed. This line includes large-scale units from Simec that allow for

treatment of many slabs at once.

In addition to producing slabs, Marmi Graniti Favorita also processes stone tiles. In this operation, blocks are first processed on one of several Simec blockcutters, which cut the blocks into workable strips. The strips are then processed into tiles on a complete Simec tile line and packaged for shipment.

In terms of marketing, Marmi Graniti Favorita is targeting growth in Italy and beyond. “The company is strongly engaged, now more than ever, in a policy of commercial expansion on the national and foreign markets,” stated Marmi Graniti Favorita. As evidence of the company’s commitment to the international marketplace, 100% of exotic production is exported, and markets include nations in Europe as well as the U.S.

The resin is either applied automatically or by hand,

depending on the material being processed.

Additional Photos

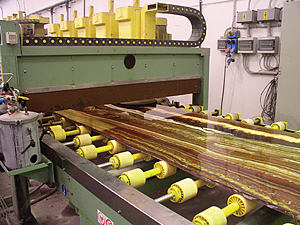

The slabs receive their final polish on one of two

Simec polishing lines.

Typically, one of the polishing lines is for

resin-treated material, while the other is for untreated slabs.

Marmi Graniti Favorita also processes stone tiles, and

blocks are first processed into strips on one of several Simec blockcutters,

and the trips are then processed into tiles on a complete Simec tile line.

The company maintains a large inventory of products at

its facility, and approximately 40% of production is resin treated. Among the

resin products in use at the plant, Marmi Graniti Favorita utilizes an

anti-bacterial epoxy resin coating from Tenax. It also uses a new Tenax resin

technology, Glaxs, which protects the material from yellowing when exposed to

UV rays.

Onyx varieties offered by Marmi Graniti Favorita

include Kilamanjaro and Meile, and the slabs can also be backlit.

Exotic granite varieties include materials with shades

of blue, such as Glacial Eyes.

The company also processes sought-after marble

varieties, including Calacatta.

A total of 100% of exotic production is exported, and

markets include nations in Europe as well as the U.S.