Ultimate Granite Surfaces (UGS) Inc. of Gibsonia, PA, was started in 2001, and it is currently under the ownership of the father-and-son team of Dwight and Chris Morrow. The company operates out of a 10,250-square-foot facility that is equipped with state-of-the-art fabrication machinery.

Ultimate Granite Surfaces (UGS) Inc. of Gibsonia, PA, is the result of a family taking a chance on a new concept in stone fabrication at the time called “thinstone.” And while this initial investment was the force that drove the company’s growth in its early days, UGS has now expanded its operation to include the fabrication of 3-cm stone and quartz surfacing products.

The company opened its doors in 2001, and since that time it has continually improved upon its success by expanding the size of its shop, adding new pieces of state-of-the-art machinery and hiring new employees. Today it is owned by Dwight Morrow, who is responsible for all field measuring, and his son, Chris, who handles all day-to-day operations.

The company’s most recent investment is the Breton FabCenter K37 CNC stoneworking center.

According to Morrow, there was minimal start-up cost for producing thinstone because very little machinery was needed. “It was fabricated mostly by hand tools and one large tile-like bridge saw,” he explained. “I found a 6,200-square-foot building and leased it for three years. We hired one guy who was in construction for years to help put the shop together, and we fabricated all of our benches, A-frames, etc. We started fabricating right away and were doing about one-and-a-half jobs a week.”

Morrow went on to say that after only having the company up and running for about six months, UGS landed a contract with a reputable builder that put thinstone in as a standard option, and they built about 25 homes that year. “Our second year, we hired two more employees that had extensive stone experience in fabrication and installation, but in 3-cm material only,” he said. “We had landed the largest builder in Pennsylvania, and that was a huge account for us. That increased our production to about three to four a week - some of these homes had about 130 square feet of granite, so they took a good day and a half just to fabricate. At that time, we were also starting to get more kitchen designers and remodelers interested in our thinstone product. We continued to grow at about a 20% rate that next year.”

“[The FabCenter] is our favorite machine yet,” said Chris Morrow, who oversees UGS’s day-to-day operation. “This gave us pretty much a whole shop with one machine. It allows us to load full slabs and unload finished pieces - minimizing the handling process.”

Although thinstone was becoming a successful product for UGS, the company wanted to offer its customers more of a selection. “We wanted to get into fabricating 3-cm stone,” said Morrow. “In the third year, we bought a Yukon bridge saw and a Wizard Deluxe radial arm polisher [from Park Industries of St. Cloud, MN]. That allowed us to pretty much fabricate anything. We also started fabricating Zodiac and CaesarStone quartz products along with natural stone. We also continued to fabricate thinstone.

“Our company was growing so fast that we seemed to make so many changes in such little time to keep up with all the competitors,” Morrow went on to say. “At this time, we were doing a little over a kitchen a day, but our man-hours kept increasing, and our lead-times got longer. We needed to go digital.”

UGS purchased a Park Industries Yukon bridge saw when it decided to start cutting 3-cm material.

In 2005, after the operation had been running for four years, UGS invested in a Sassomeccanica Flying Flat edge machine, currently serviced by SassoAmerica of St. Louis, MO. “That was a life saver,” said Morrow. “We no longer had to polish backsplashes by hand. We hired two more guys and continued to fabricate by hand with Ghines Sector routers, but we were making less profit and working more hours and producing the same amount. Our sales, however, continued to increase at the same rate.”

In the shop, three fabricators are responsible for cutting and finishing the slabs.

Two years later, UGS purchased a new 10,250-square-foot facility with 12,000 square feet of outdoor slab storage space. At this time, the company also invested in its first CNC machine - an Intermac Master 33. “It was a major step for us to move all of our inventory and machines,” said Morrow. “It was a big adjustment, but a good one. We also added two more employees that had CNC experience. We instantly became a higher quality shop overnight with shorter lead-times and less overtime.”

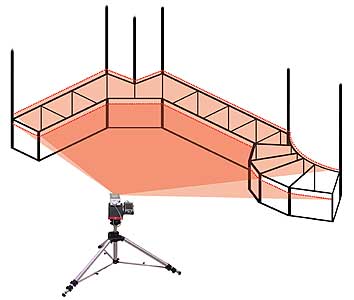

Six months after moving into its new facility, UGS made another investment to further increase its efficiency. “We bought an LT-55 Laser Templator [from Laser Products of Romeoville, IL] and became fully digital,” said Morrow. “It was a great investment for us. This allowed us to become 100% digital and more accurate in the templating process. We still print out vinyl templates from our ADSI vinyl plotter machine for a double check.”

Additional equipment used by UGS in its production process includes a Tesimeg water treatment system, vacuum lifters from Wood’s Powr-Grip of Mt. Laurel, MT, and a Gorbel overhead crane supplied by GranQuartz of Tucker, GA. Job Tracker job tracking and estimating software - manufactured by Moreware of Reno, NV - is used to maintain records of each job, two box trucks are fully equipped with all installation tools and there are also two pick-up trucks.

UGS’s extensive slab inventory is kept in a 12,000-square-foot outdoor area.

The company’s most recent investment is the Breton FabCenter K37 CNC stoneworking center. “This is our favorite machine yet,” said Morrow. “This gave us pretty much a whole shop with one machine. It allows us to load full slabs and unload finished pieces - minimizing the handling process. Along with the machine, we purchased Breton’s software for all our inventory so we can manage every single piece of material that comes in and out of our shop. We can also do a customer’s layout of their kitchen on their exact material and offer them a three-dimensional rendering to approve. Each slab is photographed through Breton ImageMaster that is networked throughout our company. Our salespeople, CAD guys, estimators and customers can all view our materials.”

In total, UGS is comprised of 13 employees, including Morrow and his father. There are three fabricators, two CAD workers, one salesperson, one project manager, two installers and two office assistants. “The most valuable asset to our company is our employees,” said Morrow. “We have a very dedicated staff that takes pride in what they do, and we have had very little turnover and would like to continue that mold.”

In 2005, after the operation had been running for four years, UGS invested in a Sassomeccanica Flying Flat edge machine, currently serviced by SassoAmerica of St. Louis, MO. “That was a life saver,” said Morrow. “We no longer had to polish backsplashes by hand.”

Overall, Morrow and his father hope UGS continues on the path it has been following since it first began. “Our short-term goal is to continue to improve every day as a team in every aspect of what we do here at UGS,” said Morrow. “For the long term, we want to continue to be a company that provides ultimate quality with excellent customer service in the high-end residential market and also be able to get more work in the commercial market.”

In 2005, after the operation had been running for four years, UGS invested in a Sassomeccanica Flying Flat edge machine, currently serviced by SassoAmerica of St. Louis, MO. “That was a life saver,” said Morrow. “We no longer had to polish backsplashes by hand.”

Sidebar: Ultimate Granite Surfaces (UGS) Inc.

Gibsonia, PAType of work: high-end residential

Machinery: A Yukon bridge saw, a Wizard Deluxe radial arm polisher -- both from Park Industries of St. Cloud, MN; a Flying Flat Edge machine from Sassomeccanica S.r.l., currently serviced by SassoAmerica of St. Louis, MO; an Intermac Master 33 CNC stoneworking center from Intermac America, Glass and Stone of Charlotte, NC; a Breton FabCenter K37 CNC stoneworking machine from Breton S.p.A. of Castello di Godego, Italy; an LT-55 precision laser templator from Laser Products of Romeoville, IL; vacuum lifters from Wood’s Powr-Grip of Mt. Laurel, MT; Job Tracker tracking and estimating software from Moraware of Reno, NV; a ADSI vinyl plotter; a Gorbel overhead crane from GranQuartz of Tucker, GA; hand tools and accessories from Braxton-Bragg of Knoxville, TN, GranQuartz; and Keystone Tools Co. of Commerce, CA; CNC tooling from Salem Stone of Winston-Salem, NC

Number of Employees: 13

Production Rate: 300 square feet (a little more than two kitchens) per day; 10 to 12 kitchens per week

A total of 90% of the company’s business is custom slab work.

Additional Photos

The LT-55 Laser Templator from Laser Products of Romeoville, IL, allowed UGS to become fully digital and more accurate in the templating process. (An example is pictured.)

High-end residential customers comprise the primary market for UGS. The company completes many kitchen countertops and islands such as the one in this private residence.

In addition to residential work, the company also completes custom slab work for establishments such as bars and restaurants.