Where are you focusing your time and energy in your business? One consideration that is often overlooked is evaluating your shop efficiency. By enhancing your shop's efficiency, you could reap literally hundreds of dollars per job, all while increasing volume and reducing fixed costs.

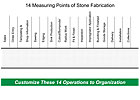

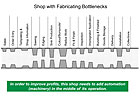

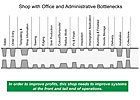

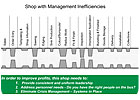

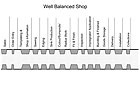

By conducting time studies on each of your areas of production, you will be able to determine the location of your bottleneck - which are limiting your operation's overall fabricating capacity. While doing a time study, there are 14 major areas of your production, as noted on the chart above.

Involve your employees

Before you conduct a time study of your operations, it is critical to get your employees involved in the process. Schedule a meeting to discuss your goals on improving the operations and how it will impact them as employees. You might be surprised how eager they are to show you what needs to be improved. If you don't involve your employees in the process, they may wonder what you are doing standing by them and clocking their every move.

Take the time to conduct a shop efficiency time study. It will be one of the best business evaluations that you can do to help you business grow and prosper.