The consortium itself is a single entity that manages the entire production process, including quarrying, primary and secondary processing, sales/marketing and, when requested, design and installation. This structure allows for optimum quality control, reliability, value and speed of delivery, explained Ute Froesa, export manager for Consorzio Cavatori Produttori Porfido.

The firms that make up the consortium are all qualified to apply the name “Porfido del Trentino†to their products, but the consortium also has its own specific brand name of KERN® porphyry to underscore the quality control.

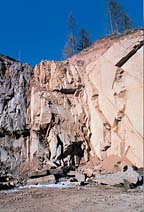

A total of 350 people work in the porphyry quarries. The stone sits vertically within the mountain, similar to slate, and the thickness is determined by the natural formation of the stone. Only some materials can be as thick as 16 inches. It's not an industrialized product,†explained Froesa. “It is decided by nature, and it passes through many hands before it becomes the final product.â€

To extract the stone, black powder explosives are used at the base of a stone wall ranging from 50 to 130 feet in height. After the material is freed and falls to the quarry floor, it is separated with Caterpillar loaders. The first worker to handle the stone has the difficult and important task of splitting the stone to the maximum thicknesses given by nature. This is critical and the most important difference in quality, because if not done properly, freeze/thaw cycles can split the stone after it has been set. From there, workers use hand tools or splitting machines to bring the stone pieces to their final dimensions, and it is loaded directly onto a palette. The waste level in the quarry runs between 50 and 60%.

The consortium controls the quality of the material, and only the best material can be sawn and flamed. By flaming the surface, the material develops a uniform gray or violet color. The stone has a naturally smooth, yet non-slip surface that makes it ideal for paving, and the mixed color range conceals staining, Froesa said. It is mainly used for exterior applications such as pavers, cubes, settes, pool coping, split-face wall cladding, pebbles, curbs and solid stairs. In addition to textured surfaces, the material can be finished with a semi-polished or polished surface, and it can also be used for interiors. Porphyry from the consortium has been used in high-profile applications such as Piazza Bra in Verona as well as a number of fashion retailers in Milan. In this sector, Froesa explained that the material provides a solid backdrop for merchandise without overwhelming a space.