Given the scope of Trapani's marble industry, it makes sense that companies such as GMS Import Export srl are in place as a hub for the various sectors of the trade. The company is actually made up of several firms in the area, including marble quarrying, stone fabrication and even equipment maintenance and sales.

GMS represents five different quarries, and sells stone as finished slabs and tiles, which are processed in Custonaci. The company also offers architectural pieces such as window sills, steps and other items.

The quarries in Custonaci include sites for Perlato di Sicilia classifications as well as Perlatino. It has also started a new quarry for Libeccio marble near the Perlato and Perlatino quarries. This material, which was used in the Vatican, has been specified for an exclusive hotel in Dubai, United Arab Emirates. Additionally, it is already being sold in the U.S. marketplace.

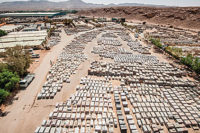

At the quarry for Perlato di Sicilia, which stands at an altitude of over 1,600 feet, stone is extracted using standard marble quarrying methods, with diamond wire saws being used for most of the cutting operations. The Perlato site represented by GMS produces a total of 700 cubic meters of stone per month, representing 150 truckloads of material.

Only a few meters away is the GMS site for Perlatino, which has a slightly higher demand than that of the Perlato. This site is also equipped with a Fantini chainsaw, in addition to diamond wire saws, and with the increased machinery and manpower, it produces 1,000 cubic meters of stone per month.

And at an even higher altitude, where a trip up the mountain trail leads past grazing cattle that calmly cross the roadway, the highly coveted Libeccio marble is quarried. At the time of Stone World's visit, workers were extracting stone while also expanding the overall size of the quarry site by removing overburden. The stone has a deep, golden tone with maroon and red veining, distinguishing itself from the other stones quarried in the region.

On the fabrication side, Marmi Eurosud is the tile-producing arm of the company, and it is equipped with two blockcutters from F. Meccanica as well as a F. Meccanica tile polishing line.

Back off the mountain, at sea level, is the slab-producing operation, which stands directly on the shore of the Mediterranean Sea. Here, slabs are polished with a River G slab polishing line from F. Meccanica, which is equipped with Tenax abrasives.

GMS exports a total of 100 containers per month, and in addition to stone from the Trapani area, it also imports material from other countries to make into slabs.

The company maintains a showroom in Carrara, Italy, where it showcases its products and conducts buyer meetings. In another interesting development, GMS is currently exploring sites in Eastern Europe to find a source of material similar to Botticino.