In the aftermath of the September 11 terrorist attacks, the damage to lower Manhattan was not limited to the World Trade Center buildings. Many architectural landmarks surrounding the complex were also damaged, some of them severely. One of these structures was the historic Barclay-Vesey Building, which is currently undergoing a restoration effort that includes the re-creation of its intricately carved limestone elements.

Originally built from 1923 to 1927 as the headquarters for New York Telephone, the Barclay-Vesey Building was significantly damaged when the fourth structure in the World Trade Center complex -- Building Seven -- collapsed. When Seven World Trade Center fell, steel girders from the building hit the ground with such incredible force that they penetrated several feet into the pavement. And as a result of the tremendous impact of the collapse and resulting debris, two of the facades at the Barclay-Vesey Building were brutally affected. The face of the brick-and-limestone building had substantial holes that peered out onto the destruction of the World Trade Center complex, and much of the carved limestone was shattered well beyond repair.

The 32-story building had been designed by McKenzie Voorhees & Gmelin Architects as the first Art Deco skyscraper, with a height of nearly 500 feet. At the time of its opening, its designers were awarded the Architectural League of New York's gold medal of honor in 1927 for "fine expression of the new industrial age." It was named the Barclay-Vesey Building after the streets to its north and south.

Although much of the exterior is brick, the feature elements of the facade are limestone, including large cubic pieces as well as ornately carved panels. The carvings depict a broad range of designs, with images of a bell -- New York Telephone's icon -- as a recurring theme throughout.

Replicating classic stonework

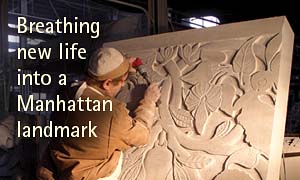

To reproduce the original limestone carvings that were destroyed, Tishman Construction, the general contractor, selected Petrillo Stone Corp. of Mt. Vernon, NY. Owners Ralph and Frank Petrillo of Petrillo Stone Corp. explained that their company has had a history of working with Tishman and that its proximity to lower Manhattan made them a nice fit for the job. "We spent days and days on the scaffolding," explained Frank Petrillo, who added that measurements are still being taken on a continual basis.To handle such a challenging task, Petrillo's carving team includes some of the New York area's top artisans in the field, including Bob Carpenter, who trained as a carver in Europe and heads the team; Michael Orekunrin, a master stone carver who was educated in Nigeria and formerly worked at the Cathedral of St. John the Divine for Cathedral Stoneworks; and shop foreman Doug Breitbart. The team also includes carvers and stonecutters Pooran Sanicharra, Ramesh Jodubar, Celine Canon and Johnny Parbhu; sandblasters Alvin Green and "Scap" Sahadeo; plannerman Fred Clayton and sawyer Joe Mangan. Alex Vays was the project manager for Petrillo Stone Corp.

To rebuild what was lost at the Barclay-Vesey Building on September 11, the carving team relied on what had survived the attack. Although two of the structure's facades were severely damaged, the stonework on the other two facades remained largely intact. And fortunately, many of the limestone designs that were destroyed on the building could also be found on the extant facades.

The first step in replicating the stonework was to take photographs and create molds of the existing stonework at the building. "We wanted to simplify things as much as possible," said Carpenter. "Every time I look at [the facade], I see something else. I took 30 to 40 molds of different areas, and we took pictures of everything. Then we took those to Astoria Graphics, and they blew them up to full size."

The images of the stonework are used to make latex matting that outlines the surface designs of the stonework. This matting is then placed over the slabs so they can be sandblasted in the same way that stone monuments are processed. A sand-blasting unit --purchased by Petrillo specifically for the Barclay-Vesey Building restoration -- is then used on the panels to achieve the necessary depth of the designs. Then, the artisans use routers set at a low speed to make sharper corners on the surface designs. By taking these steps, the carvers are able to complete the detailing of what is already dimensioned, and they do not have to spend an excessive amount of time removing surface material.

"We wanted to keep everything as close to the original as possible," Carpenter said. "The [original carvers] were brilliant. From the street level, you really learn the feel of the building. Even at two stories up, the detailing of the panels is incredible." To further convey the character of the original facade, the full-sized photos of the stonework are set up in the shop for the carvers to reference while they work.

The limestone is quarried by Victor Oolitic Stone Co. of Bloomington, IN, and it is cut into slabs by Michael & Sons of Bloomfield, IN. While the thinner slabs are 5 or 6 inches in thickness, some of the pieces were much larger. At the entrance, for example, pieces are as thick as 16 inches.

Before being delivered to the job site in Manhattan, all of the finished pieces are classified by number at Petrillo's shop so the installers can easily determine exactly where each piece should be installed. In total, the project will require 5,000 cubic feet of Indiana limestone, with 2,000 square feet of finished surface area.

In addition to the limestone, the project also requires approximately 500 cubic feet of Stony Creek granite for the base of the building. This stone was quarried in Connecticut by Granicor, a Canadian firm, and it is supplied through Furlong & Lee of New York.

The reconstruction of the Barclay-Vesey Building is expected to be completed by September of this year. Petrillo Stone Corp. is also responsible for the installation of the new limestone and granite, and it is starting work on the project this month with a crew of six to nine workers.